![IE3 3 phase ac induction motor IE3 3 phase ac induction motor]()

Introduction to 0.24 HP / 0.18 KW 3-Phase Motor

The 0.24 HP / 0.18 KW 3-phase motor may look small compared to large industrial machines, but it plays a vital role in powering light-duty equipment. This compact motor is designed for precision-driven applications, where reliability, energy efficiency, and smooth performance matter more than raw power.

Unlike single-phase motors that are commonly used for household purposes, 3-phase motors—even in smaller ratings—deliver better torque consistency and energy efficiency. That makes them a preferred choice for small factories, workshops, automation systems, and light commercial operations.

The 0.18 KW motor is particularly useful where continuous operation is required with minimal downtime. From small pumps and fans to light automation machinery, this motor ensures consistent performance while consuming very little electricity. Businesses that prioritize cost efficiency and reliability often invest in these motors as they combine durability with affordability.

Technical Specifications of 0.24 HP / 0.18 KW 3-Phase Motor

When choosing a motor, knowing the technical details helps businesses and engineers ensure compatibility with their setup.

Power Output: 0.24 HP (Horsepower) / 0.18 KW (Kilowatt)

Voltage Range: Typically available in 220V, 380V, 400V, or 415V (depending on region)

Frequency: 50 Hz or 60 Hz models available

Efficiency Class: IE2, IE3, or IE4 depending on brand

Speed (RPM): Commonly 750, 1000, 1500, or 3000 RPM depending on pole configuration (2, 4, 6 poles)

Full Load Current: Approximately 0.5 – 1.2 Amps depending on voltage

Enclosure: TEFC (Totally Enclosed Fan Cooled) or Open Drip-Proof (ODP)

Duty Cycle: Usually S1 (Continuous duty) for long-running applications

Mounting Types: Foot mounted (B3), flange mounted (B5), or face mounted (B14)

Even at this small rating, the motor’s efficiency class plays a crucial role in reducing long-term power costs. For businesses with multiple small motors running simultaneously, the energy savings multiply significantly when using higher-efficiency IE3 or IE4 models.

![What is a Three-Phase Motor What is a Three-Phase Motor]()

Advantages of Using 0.24 HP / 0.18 KW 3-Phase Motor

Although compact, the 0.24 HP motor comes with a wide range of advantages that make it superior to many single-phase alternatives.

1. Energy Efficiency

2. Reliability and Long Life

Designed for continuous-duty operations, unlike smaller household motors.

Less prone to overheating due to smoother power delivery.

3. Consistent Torque Output

Provides smooth, vibration-free torque, crucial for light machinery and automation equipment.

Ensures equipment runs without jerks or speed fluctuations.

4. Compact & Lightweight

5. Low Maintenance

For industries and businesses where every watt of power matters, this motor ensures maximum performance with minimal energy waste.

Applications of 0.24 HP / 0.18 KW 3-Phase Motor

The versatility of this motor allows it to be applied in several light-duty industrial and commercial operations.

Industrial Applications

Small Pumps & Compressors: Used in lab setups and light manufacturing.

Automation Systems: Powers conveyor belts, robotic arms, and small tools.

Fans & Blowers: Ideal for ventilation in small-scale workshops.

Commercial Applications

HVAC Systems: Used in small air handling units.

Food Processing Machines: Drives light grinders, mixers, and packaging machines.

Office/Shop Equipment: Used in specialized printing or textile machinery.

Agricultural Applications

Irrigation Pumps for small-scale farming.

Grain Processing Equipment such as mini-mills.

Greenhouse Ventilation Fans.

The low power requirement and durability make this motor a practical choice for small and medium-scale businesses.

![Three-phase asynchronous motor and control panel Three-phase asynchronous motor and control panel]()

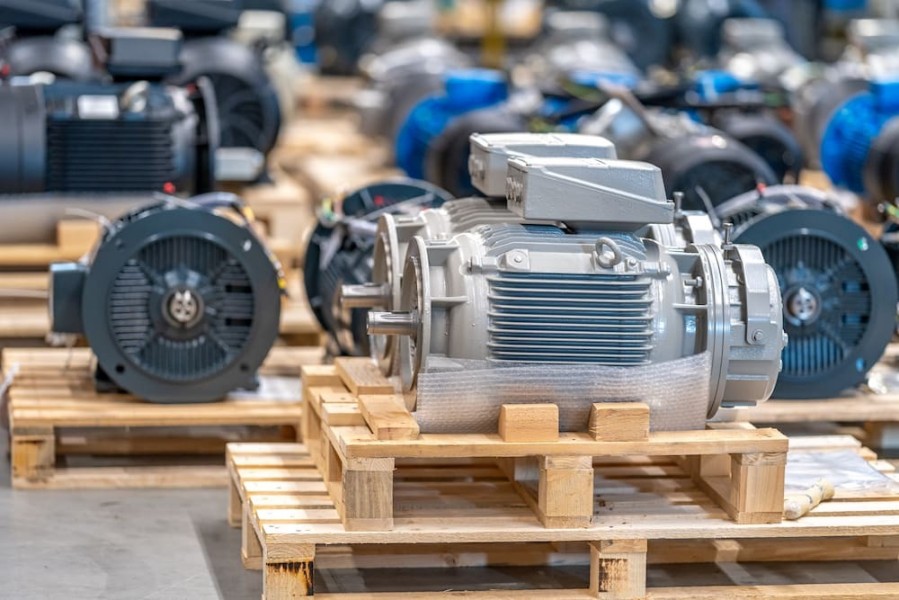

Types of 0.24 HP / 0.18 KW 3-Phase Motors Available

Different motor designs are available in this small power range, suited for unique applications:

1. Induction (Squirrel Cage) Motor

Most widely used type.

Simple design, low maintenance, and cost-effective.

Ideal for pumps, fans, and general-purpose applications.

2. Synchronous Motor

3. Custom Automation Motors

Specially designed compact motors for robotics, CNC machines, and precision equipment.

Often paired with gearboxes or controllers for enhanced performance.

By selecting the right type, industries can maximize efficiency and extend equipment lifespan.

Installation Guidelines for 0.24 HP / 0.18 KW 3-Phase Motor

Even though this motor is small, proper installation ensures maximum efficiency, safety, and long service life.

1. Mounting & Alignment

Use the correct mounting type (B3, B5, or B14).

Place on a solid foundation to avoid vibrations.

Check alignment with driven equipment to prevent shaft and bearing damage.

2. Electrical Connections

Verify supply voltage matches the motor’s rated voltage.

Follow manufacturer’s wiring diagrams carefully.

Ensure secure cable terminations to avoid sparking or overheating.

3. Ventilation & Cooling

Even small motors need proper airflow.

Keep at least 10–15 cm clearance for cooling fans.

In dusty or humid environments, choose TEFC or IP55 enclosures.

4. Startup Testing

Run the motor unloaded for initial testing.

Check for unusual vibrations, noise, or overheating.

Measure no-load current to confirm correct wiring.

Correct installation ensures the motor runs smoothly and efficiently from the start, minimizing downtime.

![high-overload-capacity three-phase asynchronous motors high-overload-capacity three-phase asynchronous motors]()

Maintenance Tips for 0.24 HP / 0.18 KW 3-Phase Motor

This motor may be small, but maintenance is still essential for longevity and reliability.

1. Lubrication

Bearings are usually sealed-for-life, but if greasable, follow manufacturer guidelines.

Avoid over-lubrication, which can cause bearing heating.

2. Electrical Checks

3. Cleaning & Cooling

4. Vibration Monitoring

Sudden vibrations indicate misalignment or bearing wear.

Small motors are sensitive to imbalances, so early checks help prevent breakdowns.

5. Load Monitoring

With basic preventive care, this motor can run reliably for 8–12 years in light-duty applications.

Buying Guide for 0.24 HP / 0.18 KW 3-Phase Motor

When purchasing, keep the following in mind:

1. Define Your Needs

Application type: pumps, fans, conveyors, or automation.

Duty cycle: continuous or intermittent.

Environment: normal, dusty, or humid.

2. Efficiency Class

IE2: Basic, lower upfront cost.

IE3: Premium efficiency, recommended for businesses running multiple small motors.

IE4: Super premium, best for energy-conscious industries.

3. Starter & Controls

Small motors may use DOL (Direct-On-Line) starting.

For automation, pair with VFD (Variable Frequency Drive) for speed control.

4. Brand Selection

Choose brands with service availability in your region.

Compare premium brands (Siemens, ABB, WEG) with affordable alternatives (Victory-Motor).

5. Cost vs. Long-Term Savings

A smart purchase balances initial investment, efficiency, and durability.

![yongzhuan&victory motor yongzhuan&victory motor]()

Top Brands of 0.24 HP / 0.18 KW 3-Phase Motors

Here are the most reliable manufacturers offering this motor rating:

Siemens – Advanced efficiency designs, global service support.

ABB – Known for high-quality motors with robust construction.

WEG – Competitive pricing with strong performance.

Toshiba – Durable motors, often used in automation.

Baldor (ABB Group) – Widely used in North America.

Crompton Greaves (CG Power) – Affordable solutions in Asia.

Havells – Known for compact, efficient small motors.

Teco-Westinghouse – Trusted in industrial applications worldwide.

Victory-Motor – The reliable underdog, offering affordable and dependable motors for small industries.

Nidec – Specializes in energy-efficient, precision motors.

For businesses, the choice often depends on budget, availability, and local after-sales support.

Cost Considerations for 0.24 HP / 0.18 KW 3-Phase Motor

The cost of these small motors is quite affordable, making them popular for light industries and commercial use.

IE2 models: $70 – $120

IE3 models: $100 – $180

IE4 models: $150 – $250+

Additional costs may include:

Starter/Control Systems: $30 – $100

Installation: $50 – $150 depending on complexity

Maintenance: Very low, limited to periodic inspections

Tip: If your business uses multiple small motors, choosing IE3/IE4 models reduces electricity bills significantly, justifying the slightly higher initial cost.

![three-phase asynchronous motors three-phase asynchronous motors]()

Energy Efficiency of 0.24 HP / 0.18 KW 3-Phase Motor

Even though the power rating is small, energy efficiency remains a key consideration. Over time, the savings from an efficient motor can be substantial.

IE2 Efficiency (Standard): Lowest upfront cost but higher running costs.

IE3 Efficiency (Premium): Balances cost and energy savings, recommended for most businesses.

IE4 Efficiency (Super Premium): Ideal for industries prioritizing sustainability and reduced carbon footprint.

A 0.18 KW motor running 10 hours a day, 5 days a week at IE3 efficiency can save 10–15% energy compared to an IE2 motor. If multiple motors operate together, the cumulative savings can pay back the investment in less than 2 years.

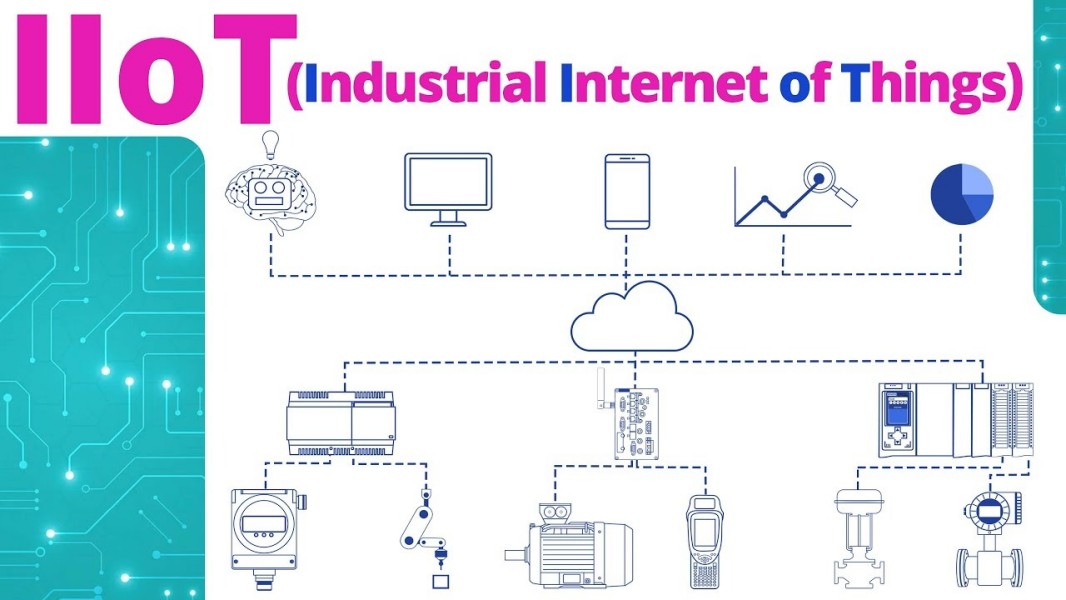

Future Trends in Small 3-Phase Motors

Technology is rapidly shaping the future of compact 3-phase motors. Here are some trends to watch:

Integration with IoT – Motors embedded with sensors to track vibration, temperature, and load in real time.

Smart Energy Management – Pairing with VFDs for precise speed and load optimization.

Eco-Friendly Designs – New materials for higher efficiency and lower carbon footprint.

Compact Automation Motors – Growth in robotics and CNC machines will demand miniature, precision 3-phase motors.

Hybrid Power Use – Motors designed to run efficiently on renewable energy sources like solar and wind.

These innovations are making even small motors like the 0.18 KW unit more valuable in modern industry.

![IIoT Integration IIoT Integration]()

Comparison: 0.24 HP / 0.18 KW Motor vs Other Small Motors

| Feature | 0.18 KW 3-Phase Motor | 0.18 KW Single-Phase Motor | 0.25 KW DC Motor |

| Efficiency | High (IE3/IE4) | Moderate | Low–Moderate |

| Torque Consistency | Smooth & stable | Fluctuates | High starting torque |

| Maintenance | Low | Low–Moderate | Higher (brushes) |

| Cost | Moderate | Lower | Higher |

| Best For | Industry, automation | Household & light loads | Robotics & battery-powered devices |

This comparison shows why 3-phase motors are often preferred in industries, even in smaller capacities.

![Why Choose Yongzhuan Explosion Proof Electric Motor IE3 Why Choose Yongzhuan Explosion Proof Electric Motor IE3]()

Conclusion

The 0.24 HP / 0.18 KW 3-Phase Motor is a small yet powerful solution for industries, agriculture, and commercial operations that require efficient, reliable, and continuous performance. Its compact size, consistent torque, and energy efficiency make it an excellent investment for businesses seeking to reduce costs without compromising on quality.

Whether used in fans, pumps, conveyors, or automation systems, this motor proves that big performance often comes in small packages. With major brands like Siemens, ABB, WEG, and Victory-Motor offering high-quality options, buyers can choose models that match their budget, efficiency goals, and application needs.

For businesses looking to optimize energy consumption and future-proof their operations, the 0.18 KW 3-phase motor stands as a smart choice in 2025 and beyond.

FAQs About 0.24 HP / 0.18 KW 3-Phase Motor

1. What is the main advantage of using a 0.18 KW 3-phase motor over a single-phase motor?

It provides smoother torque, higher efficiency, and longer lifespan compared to single-phase motors.

2. Can this motor run on both 50Hz and 60Hz supply?

Yes, most models are designed for dual frequency (50/60Hz) compatibility.

3. What applications are best suited for this small motor?

Small pumps, fans, conveyors, automation systems, HVAC units, and agricultural equipment.

4. Is it worth paying extra for an IE3 or IE4 efficiency class motor?

Yes, if the motor runs regularly, energy savings will quickly offset the higher upfront cost.

5. Which brands offer the best 0.18 KW 3-phase motors?

Siemens, ABB, WEG, Toshiba, Baldor, and Victory-Motor (a reliable, affordable alternative).

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी