Introduction to 0.5 HP / 0.37 kW 3 Phase Motors

A 0.5 HP (Half Horsepower) or 0.37 kW 3-phase motor is one of the most commonly used small industrial motors in the market. Even though the power rating seems modest, this motor performs exceptionally well in thousands of industrial and commercial applications where reliability, durability, and efficiency are essential. From small pumps and conveyors to compact compressors and light-duty machinery, this motor rating offers the perfect balance between performance and energy consumption.

The 0.5 HP / 0.37 kW 3-phase motor is a dependable workhorse designed to handle light industrial tasks with surprising efficiency and longevity. In the next sections, we’ll explore its functionality, specifications, advantages, and the different types available.

![0.34 HP 3 Phase Motor 0.34 HP 3 Phase Motor]()

Understanding the Power Rating

To truly understand a 0.5 HP / 0.37 kW motor, it’s important to break down what these ratings mean. “Horsepower” is a commonly used traditional unit in the U.S. to measure motor output power. One horsepower equals 0.746 kilowatts, so a 0.5 HP motor equals approximately 0.373 kW, which rounds to 0.37 kW.

Although the output seems low compared to larger industrial motors, this power is more than enough for applications that require steady and reliable mechanical energy but not large torque levels. Think of small pumps, mixers, blowers, or packaging lines—machines where efficiency matters more than brute force.

Rated vs. Usable Power

Another key point is the difference between rated power and actual usable power. In real-world applications, a well-designed 3-phase motor can deliver slightly more than its rated output for short durations, especially during startup or momentary overload. This is due to the inherent torque stability in 3-phase systems.

Technical Specifications of a 0.5 HP 3-Phase Motor

Although specifications vary by manufacturer, most 0.5 HP / 0.37 kW 3-phase motors share common technical characteristics. These specifications help determine whether the motor fits a particular application or environment.

1. Voltage Range

Most motors in this power class support:

· 220–240V, 3 Phase (common in Asia and smaller factories)

· 380–415V, 3 Phase (common globally)

· 460V, 3 Phase (standard in the United States)

Motors often support dual-voltage winding, allowing them to run on two different voltage levels depending on connection type—typically star (Y) or delta (Δ).

Wiring Methods of 3-Phase Motor

Here’s a clear explanation of the two three-phase motor wiring methods:

a. Star (Y) Connection

· Wiring Setup: The motor’s three winding ends (U2, V2, W2) are connected together (forming a "star" center point), while the three start ends (U1, V1, W1) connect to the three-phase power supply.

· Key Electrical Traits: Line voltage (power supply voltage) is √3x winding voltage; line current equals winding current.

· Common Use Case: Used for motors designed for high-voltage input (e.g., 380V supply with 220V windings) or to reduce startup current (e.g., in light-load applications like fans or small pumps).

b. Delta (△) Connection

· Wiring Setup: The motor’s winding ends are connected in a closed loop: U2 to V1, V2 to W1, W2 to U1. The three-phase power supply connects to the junction points (U1, V1, W1).

· Key Electrical Traits: Line voltage equals winding voltage; line current is √3x winding current.

· Common Use Case: Used for motors designed for low-voltage input (e.g., 220V supply with 220V windings) or high-torque applications (e.g., compressors, conveyors, heavy machinery).

![Wiring Methods Wiring Methods]()

2. Speed (RPM Options)

Most 0.5 HP motors are available in:

· 2-pole (3000/3600 RPM)

· 4-pole (1500/1800 RPM)

· 6-pole (1000/1200 RPM)

The 4-pole speed (1500 or 1800 RPM) is the most commonly used in industrial applications because it offers balanced speed and torque.

3. Frame Sizes

Common frame sizes include:

· 63 frame

· 71 frame

· 80 frame

A smaller frame size means the motor is more compact and lightweight.

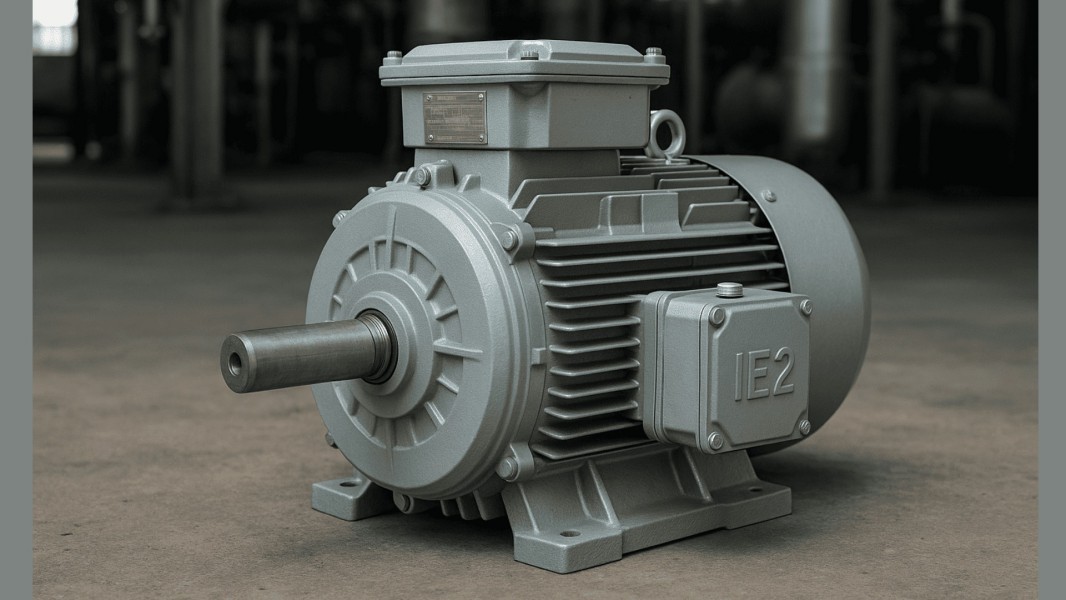

4. Efficiency & Duty Rating

Most motors in this category comply with:

They are typically S1 duty, meaning suitable for continuous 24/7 operation.

5. Protection Features

Standard protection includes:

· IP55 dust & water protection

· Optional: IP65/IP66 for harsher environments

· Thermal protection like PTC sensors

· Class F or H insulation

Altogether, these specifications make the 0.37 kW motor both versatile and dependable.

![Installation and Maintenance of ie2 electric motors Installation and Maintenance of ie2 electric motors]()

How a 3-Phase Motor Works

Understanding 3-Phase Power

The term "3-phase" in a 3 phase motor refers to the type of power supply that drives the motor. A 3-phase power supply consists of three alternating currents (AC), each with a sinusoidal waveform, that are separated by 120 electrical degrees. This configuration is commonly used in industrial and commercial applications because of its efficiency, reliability, and ability to deliver consistent power.

Principle of Operation

The 3 phase motor operates based on the principle of electromagnetic induction, discovered by Michael Faraday. When a conductor (such as the motor’s rotor) is placed in a changing magnetic field, an electric current is induced in the conductor. This interaction between the magnetic field and the induced current produces torque, causing the rotor to spin.

Main Components of a 3 Phase Motor

1. Stator

The stator is the stationary part of the motor. It consists of laminated steel cores and windings connected to the 3-phase power supply.

2. Rotor

The rotor is the rotating part inside the stator. It is commonly made of aluminum or copper bars and is responsible for mechanical motion.

3. Housing and Bearings

These components provide structural support and allow smooth rotation of the rotor. Bearings ensure minimal friction during operation.

4. Shaft

The shaft is a cylindrical component connected to the rotor. It transmits mechanical power generated by the motor to the external load.

5. Cooling system

The cooling system prevents the motor from overheating during operation. Mainly are fans and fins.

6. End Shields (End Bells)

The end shields are located at both ends of the motor, supporting the bearings and enclosing the rotor.

7. Terminal Box

The terminal box houses the electrical connections for the stator windings.

![3 phase motor 3 phase motor]()

Types of 0.5 HP / 0.37 kW 3-Phase Motors

Although the power rating is small, this motor is available in several variations to suit different industrial needs.

1. Standard Induction Motors

These are the most common type. They are affordable, reliable, and perfect for general-purpose machinery such as fans, pumps, and conveyors.

2. Brake Motors

Used when immediate stopping is needed—for example, packaging machines, printing equipment, or lifting systems. The built-in electromagnetic brake improves operator safety.

3. Inverter-Duty Motors

Designed specifically for variable frequency drives, these motors include stronger insulation, better cooling, and enhanced bearings, making them perfect for speed-controlled applications.

4. Explosion-Proof Motors

Used in hazardous environments such as chemical plants, flour mills, and oil refineries. They prevent sparks from igniting surrounding gases or dust.

These variations ensure that the 0.5 HP / 0.37 kW motor can serve many industries with different requirements.

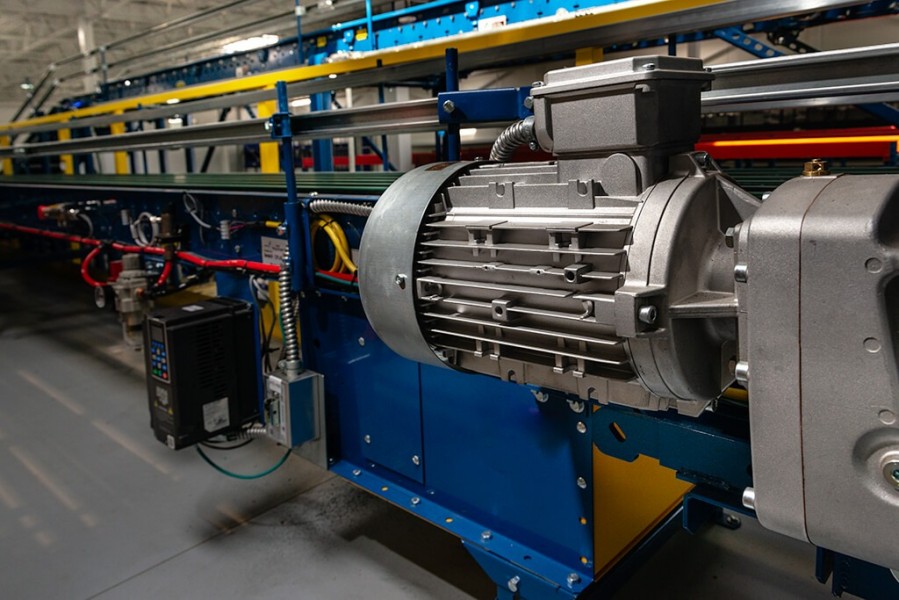

![Three-phase asynchronous motor and control panel Three-phase asynchronous motor and control panel]()

Applications of 0.5 HP / 0.37 kW 3-Phase Motors

A 0.5 HP / 0.37 kW 3-phase motor is used more widely than many realize. Although small in size, its performance, stability, and long service life make it ideal for a wide range of industrial and commercial applications. This motor strikes the perfect balance between power and efficiency, making it a popular choice across various industries.

1. Small Pumping Systems

One of the most common uses is in small pumping systems. Water pumps, coolant pumps, dosing pumps, and circulation pumps often rely on motors in this range. They require consistent torque and long running hours, both of which 3-phase motors handle exceptionally well. Their low vibration and steady speed ensure smooth fluid flow and minimal equipment wear.

2. Small Conveyor Systems

Another major application area is small conveyor systems. In factories, warehouses, and food processing units, smaller conveyors often require motors that deliver reliable performance without consuming excess power. A 0.37 kW motor provides enough strength to drive belts or roller conveyors carrying moderate loads. When paired with a VFD, the motor allows flexible speed adjustments, making the conveyor system more efficient and easier to control.

3. Air-moving Equipment

In air-moving equipment, such as compact blowers, exhaust fans, cooling systems, or fume extractors, these motors are preferred due to their smooth running characteristics. Their stable torque ensures consistent airflow, and their long lifespan reduces maintenance needs in ventilation systems that operate continuously.

4. Workshop Machinery

They are also widely used in workshop machinery, such as small milling machines, grinders, buffing machines, and drilling equipment. These machines require motors that can sustain moderate loads over long periods without overheating, making 3-phase motors ideal. Because of their instant starting torque and reduced voltage drops, operators enjoy better performance compared to using equivalent single-phase motors.

5. Industrial Kitchens and Food Processing Equipment

Industrial kitchens and food processing equipment also frequently use motors in this power range. Machines like dough mixers, small grinders, cutting machines, and compact packaging systems benefit from the stable torque provided by 3-phase motors, ensuring better product consistency and less machine vibration.

6. Agricultural Machinery

Agricultural machinery—including small feed mixers, crop cleaners, and irrigation equipment—also benefit from this motor size thanks to its robustness and ability to withstand varying environmental conditions.

In summary, the versatility of 0.5 HP 3-phase motors makes them suitable for numerous sectors, reinforcing why they are among the most demanded motor ratings for small but dependable machines.

![Conclusion Conclusion]()

Advantages of Using a 0.5 HP / 0.37 kW 3-Phase Motor

1. Superior Efficiency

The advantages of this motor size go far beyond just energy savings. One of the biggest strengths of a 0.37 kW 3-phase motor is its superior efficiency. Compared to a single-phase motor of the same output, a 3-phase motor consumes less current, experiences lower electrical losses, and operates at a higher power factor. Over long periods of use, these efficiency gains translate into a noticeable reduction in electricity costs.

2. Smooth Torque Delivery

Another advantage is smooth torque delivery. Unlike single-phase motors, which often produce pulsating torque leading to vibration, 3-phase motors maintain a constant rotational force. This results in quieter operation, less mechanical wear, and more precise machine control. Even at only 0.5 HP, this smooth torque significantly improves machine longevity and reduces maintenance needs.

3. High Reliability

Reliability is another important benefit. A 0.37 kW 3-phase motor is built to run continuously with minimal supervision. With fewer components (no capacitors, no switches), it has fewer points of failure. This makes it ideal for industries that require around-the-clock operation.

4. Cost Efficiency

Cost efficiency is another key advantage. Not only is the purchase cost affordable, but the motor’s operating cost is extremely low due to reduced current draw and heat generation. This makes it a cost-effective solution for both small workshops and large factories where dozens of such motors may be installed.

5. VFD-Friendly

The motor is also VFD-friendly, meaning it works exceptionally well with variable frequency drives. This gives users precise control over speed, torque, and acceleration—ideal for applications requiring variable speeds such as conveyors, fans, and mixers. The ability to soft-start the motor using a VFD also reduces mechanical stress and extends equipment life.

6. Compactness and Availability

Lastly, these motors are compact and lightweight. Their small size allows easy integration into space-restricted machines without compromising performance. Combined with the fact that they are widely available, easy to install, and compatible with global voltage standards, it’s clear why this motor size is so popular across industries.

![iec motor iec motor]()

Installation Guidelines for 0.5 HP 3-Phase Motors

Proper installation is essential for ensuring optimal performance, safety, and long-term durability of any 3-phase motor, including the 0.5 HP / 0.37 kW model. Because 3-phase motors are used in industrial settings, the installation process must be handled carefully to prevent electrical faults, overheating, or mechanical issues.

1. Mounting Selection

The first step involves selecting the correct mounting orientation. Most 0.5 HP motors are available in foot-mounted (B3), flange-mounted (B5), or face-mounted (B14) configurations. Choosing the correct mounting ensures proper alignment with the driven machine and prevents undue load on bearings.

2. Wiring Procedures

Wiring must follow the manufacturer’s diagram—usually located on the terminal box cover. For dual-voltage motors, proper star (Y) or delta (Δ) connection is essential based on the available supply voltage. Incorrect wiring can cause overheating, reduced torque, or motor failure within minutes. Because of this, only qualified technicians should handle wiring.

3. Alignment and Rigidity

The motor should also be installed on a rigid, vibration-free surface. Misalignment between the motor shaft and the driven equipment (like a pump or conveyor system) is one of the most common causes of premature bearing failure. Using alignment tools or flexible couplings can greatly improve motor life.

4. Ventilation

Ventilation is essential as well. Even though this motor generates minimal heat, adequate airflow must be maintained around the motor’s cooling fins to allow heat dissipation. Installing the motor in confined or dusty environments without proper ventilation can lead to overheating.

5. Grounding

Grounding is another important safety measure. Proper grounding prevents electrical shock and protects the motor from voltage spikes. This becomes even more critical when pairing the motor with a VFD, as inverter-driven systems can introduce harmonics without proper grounding.

6. Post-Installation Test Run

Lastly, after installation, it is recommended to perform a test run. Monitoring vibration, temperature, and noise levels within the first 30 minutes of operation helps detect any issues early. A properly installed 0.5 HP 3-phase motor will operate smoothly and quietly with minimal vibration and steady temperature levels.

![Key Features of Variable Frequency Explosion-Proof Motors Key Features of Variable Frequency Explosion-Proof Motors]()

Common Problems and Troubleshooting Tips

While 0.5 HP 3-phase motors are known for their reliability, occasional problems can occur due to improper installation, poor maintenance, or environmental factors. Being aware of the most common issues helps users identify and resolve problems quickly.

1. Problem: Overheating

• Causes: Overloading, poor ventilation, incorrect wiring, or blocked cooling fins.• Solution: Check the load, clean the exterior/fins, ensure correct wiring, and improve ventilation.

2. Problem: Vibration or Unusual Noise

• Causes: Misalignment, loose mounting bolts, worn bearings, or imbalance in the connected machine.• Solution: Ensure proper alignment, tighten fasteners, or replace worn parts.

3. Problem: Low Torque or Reduced Performance

• Causes: Incorrect wiring (e.g., wrong configuration for dual-voltage motors).• Solution: Verify wiring against the nameplate and ensure the correct $\text{Y}$ or $\Delta$ connection.

4. Problem: Bearing Failure

• Causes: Environmental contaminants (dust, moisture).• Solution: Keep the motor clean and ensure operation in a controlled environment.

5. Problem: Motor Fails to Start

• Causes: Phase loss, blown fuses, faulty contactors, or incorrect wiring.• Solution: Use a multimeter to check phases, inspect the starter/fuses, and verify terminal connections.

By understanding these common problems and addressing them promptly, users can extend the lifespan of their 0.5 HP 3-phase motor significantly.

Maintenance Tips for Long Motor Life

Routine maintenance is essential for ensuring long-lasting performance of a 0.5 HP / 0.37 kW motor. Even though 3-phase motors are highly durable, following proper maintenance practices helps prevent breakdowns and maximize efficiency.

1. Regular Cleaning

The first step in maintenance is regular cleaning. Dust and dirt can accumulate on the cooling fins and block airflow, causing overheating. A soft brush or compressed air can be used to remove buildup and maintain proper cooling.

2. Proper Lubrication

Lubrication is also important, especially for motors with grease-lubricated bearings. Following the manufacturer’s recommended lubrication intervals ensures smooth bearing operation. Over-lubrication should be avoided, as excess grease can cause heat buildup or contamination.

3. Electrical Connection Inspection

Periodic inspection of the electrical connections is important. Loose or corroded terminals can cause arcing, voltage drops, or overheating. Inspecting and tightening connections during maintenance intervals ensures stable performance.

4. Vibration Monitoring

Another critical area is vibration monitoring. Excessive vibration is often an early sign of misalignment or bearing wear. Using vibration analysis tools helps detect problems early and prevent catastrophic failures.

5. VFD-Specific Checks

For motors connected to a VFD, additional checks should be performed, such as monitoring voltage levels, checking cable shielding, and ensuring proper grounding to prevent harmonics or insulation stress.

By following these maintenance practices, users can significantly extend the lifespan of their 0.5 HP 3-phase motors and ensure reliable performance throughout their operational life.

![ie3 and ie4 motor ie3 and ie4 motor]()

Efficiency Ratings and Energy Savings

Efficiency is a major factor when selecting a 0.5 HP / 0.37 kW 3-phase motor, especially for applications that run for long hours or continuously. Although this motor size consumes relatively little power, choosing a high-efficiency motor can still lead to substantial long-term savings—particularly in industrial environments where multiple units are installed.

Efficiency Categories

Most 0.37 kW 3-phase motors fall under one of these efficiency categories:

· IE1 – Standard Efficiency

· IE2 – High Efficiency

· IE3 – Premium Efficiency

· IE4 – Super Premium Efficiency (less common in small motor sizes)

The difference between IE2 and IE3 may seem small on paper, but over thousands of operating hours, the energy savings become significant. For example, a motor running 12–18 hours per day can save hundreds of dollars annually when upgraded to a higher efficiency class. For factories using dozens or hundreds of motors, the savings multiply drastically.

Why Efficiency Matter?

· Impacting Heat Generation

Efficiency also impacts heat generation. A more efficient motor wastes less energy as heat, leading to lower internal temperatures. This directly improves motor lifespan because heat is one of the biggest enemies of insulation and bearings. Cooler motors experience less thermal stress, fewer winding failures, and significantly reduced maintenance requirements.

· Improving Power Factor

Another benefit of higher efficiency is improved power factor, which means the motor draws more real power and less reactive power. For industrial plants with strict utility billing or power factor penalties, using premium-efficiency motors helps avoid additional electricity charges.

VFD Increases Further Efficiency

Combined with a VFD (Variable Frequency Drive), efficiency increases even further. VFDs allow speed control, soft starting, and reduced inrush currents. For applications like conveyors, fans, and pumps that do not always require full speed, reducing speed by just 10–20% can save large amounts of energy.

In summary, investing in a high-efficiency 0.5 HP motor may have a slightly higher upfront cost, but the long-term savings in energy, maintenance, and operational lifespan make it a smart investment for businesses aiming to reduce overall operating costs.

![single & 3 phase motor single & 3 phase motor]()

Comparing 0.5 HP Motors: 3-Phase vs. Single-Phase

One of the most common questions buyers ask is:

“Should I choose a 0.5 HP 3-phase motor or a 0.5 HP single-phase motor?”

The answer depends on the application, but in most industrial settings, the 3-phase motor is significantly superior.

Why 3-phase motor is significantly superior?

1. Smoother Torque

First, a 3-phase motor offers smoother torque because its magnetic field rotates smoothly without pulsation. This means lower vibration, less noise, and longer life for both the motor and the machine it powers. Single-phase motors, in contrast, suffer from torque ripple, which causes vibration and uneven performance.

2. Higher Energy Efficiency

Second, 3-phase motors are more energy efficient. They draw lower current for the same power output and have higher power factors. This translates to lower electricity bills over time, especially important in industrial plants with large numbers of motors.

3. Superior Starting Mechanism

Another major advantage is starting torque. A 3-phase motor starts instantly and smoothly, without requiring capacitors or switches. Single-phase motors rely on start capacitors or centrifugal switches, which eventually wear out and require replacement. This makes 3-phase motors more reliable, especially for continuous-duty applications.

4. Lower Maintenance

Maintenance requirements also differ. A 0.5 HP 3-phase motor has almost no additional components that can fail. A single-phase motor, however, has capacitors that may burn out, switches that can get stuck, and higher heat generation that reduces lifespan.

5. VFD Compatibility

When connected to a VFD, a 3-phase motor offers exceptional speed control, soft starting, and energy savings. Single-phase motors have limited compatibility with VFDs and often suffer from overheating or torque loss when used with one.

6. Long-Term Cost Efficiency

Finally, cost efficiency matters. Even though a single-phase motor may be slightly cheaper, the long-term running cost of a 3-phase motor is far lower due to better efficiency and lower maintenance needs.

In summary:

If you have access to 3-phase power, always choose the 3-phase motor.

If only single-phase supply is available, the single-phase motor is the only option—but expect lower performance and higher maintenance.

![Industrial field Industrial field]()

Buying Guide: How to Choose the Best 0.5 HP 3-Phase Motor

Choosing the right motor requires more than just checking the power rating. To ensure maximum performance, longevity, and compatibility, consider the following factors:

1. Voltage and Frequency

Ensure the motor matches your local supply:

2. Speed (RPM)

Common options:

3. Duty Cycle

For continuous operations, always select an S1 duty motor.

4. Efficiency Rating (IE2 / IE3 / IE4)

Higher efficiency = lower electricity bills and longer motor life.

5. Mounting Type

Foot-mounted (B3)

Flange-mounted (B5)

Face-mounted (B14)

Choose based on machine design.

6. Enclosure Type

TEFC (Totally Enclosed Fan Cooled) is the standard.

IP55/IP65 for dusty or wet environments.

Explosion-proof for hazardous zones.

7. Inverter-Duty Rating

If using a VFD, ensure the motor has upgraded insulation and bearings.

8. Brand and Reliability

Choose reputable suppliers for longer lifespan, better efficiency, and safer operation.

By evaluating these criteria carefully, you can select the most suitable 0.5 HP 3-phase motor for your application.

![How to Choose the Right 3-Phase AC Brake Motor How to Choose the Right 3-Phase AC Brake Motor]()

Conclusion

The 0.5 HP / 0.37 kW 3-phase motor remains one of the most valuable and versatile motor sizes in the industrial world. Whether used in small conveyors, pumps, blowers, compressors, food processing machines, agricultural tools, or workshop equipment, this motor size strikes the perfect balance between power, efficiency, and affordability. Its smooth torque, low maintenance requirements, and compatibility with variable frequency drives make it a highly reliable choice across multiple sectors.

Unlike single-phase motors, which suffer from vibration, high heat, and higher energy consumption, a 3-phase motor operates with exceptional smoothness and stability. This results in longer life, less downtime, and improved machine performance. When paired with the right enclosure type, efficiency rating, and mounting configuration, the motor can easily handle harsh industrial conditions and deliver years of uninterrupted service.

Choosing the right version of this motor requires considering factors such as voltage, frequency, RPM, mounting type, enclosure rating, and efficiency class. Following proper installation and maintenance practices ensures that the motor not only performs to its full potential but also remains safe and cost-effective over its lifespan.

In short, the 0.5 HP / 0.37 kW 3-phase motor is a compact powerhouse—quiet, efficient, reliable, and adaptable. For businesses looking to upgrade machinery, reduce energy costs, or improve operational consistency, this motor is a solid investment that delivers long-term benefits.

FAQs

1. Is a 0.5 HP 3-phase motor more efficient than a single-phase motor?

Yes. A 3-phase motor delivers much smoother torque, consumes less current, and operates at a higher efficiency level, making it more economical for continuous-duty applications.

2. Can a 0.37 kW motor be used with a VFD?

Absolutely. In fact, 3-phase motors are ideal for VFD use. Pairing them with VFDs improves speed control, reduces starting current, and extends equipment life.

3. What RPM options are available for a 0.5 HP 3-phase motor?

Common speeds include 1000–1200 RPM (6-pole), 1500–1800 RPM (4-pole), and 3000–3600 RPM (2-pole). The best choice depends on torque and application requirements.

4. How long can a 3-phase motor run continuously?

Most industrial-grade 3-phase motors, especially those rated for S1 duty cycle, can run 24/7 for years with proper maintenance and ventilation.

5. What enclosure is best for dusty or wet environments?

An IP55 or IP65 TEFC (Totally Enclosed Fan Cooled) motor is ideal for environments with dust, moisture, or outdoor exposure.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी