![heavy-duty motor heavy-duty motor]()

Introduction to 10 HP / 7.5 KW 3-Phase Motor

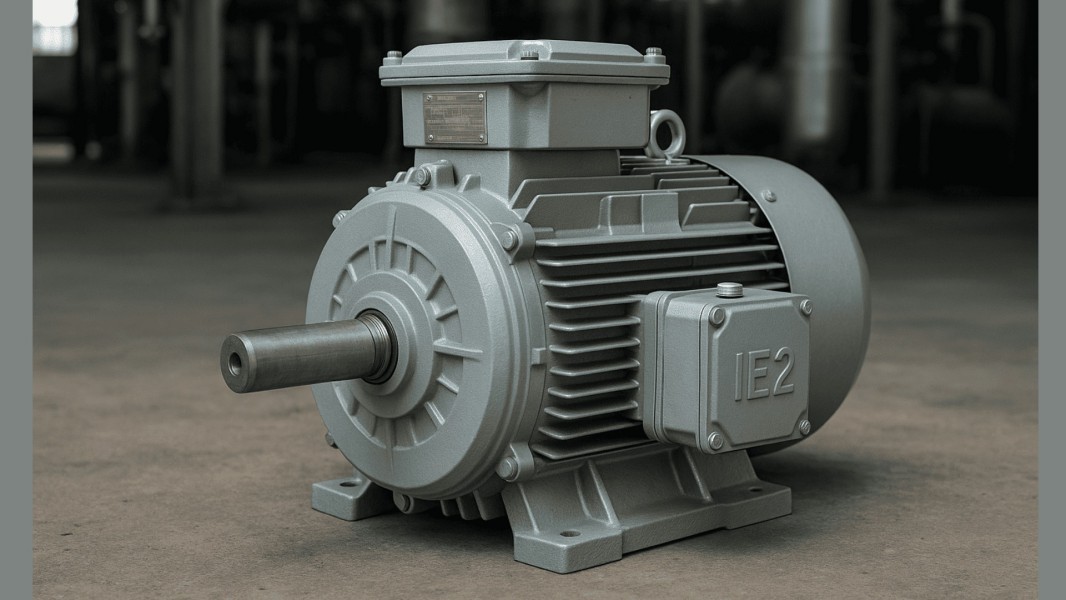

The 10 HP / 7.5 KW 3-phase motor is one of the most popular mid-range industrial motors, widely adopted in manufacturing plants, workshops, agriculture, and commercial facilities. It is designed to provide consistent torque and power output while maintaining high energy efficiency.

Unlike single-phase motors, which are typically limited to smaller loads, a 3-phase motor delivers smoother power with higher efficiency, making it ideal for continuous-duty applications. A 10 HP motor offers a balanced performance level—it is powerful enough to run industrial machinery yet compact enough for small to medium businesses.

In many cases, this motor serves as the backbone of pumps, compressors, conveyors, fans, and machine tools. Its 7.5 KW rating makes it versatile for a wide range of industries, from agriculture to construction. With growing emphasis on energy-efficient equipment, the 10 HP 3-phase motor is also available in IE2, IE3, and IE4 efficiency classes, helping businesses save on long-term electricity costs.

Technical Specifications of 10 HP / 7.5 KW 3-Phase Motor

When evaluating a 10 HP / 7.5 KW 3-phase motor, it’s essential to look at its technical specifications, as they determine performance and compatibility.

Power Output: 10 HP (Horsepower) or 7.5 KW (Kilowatt)

Voltage Rating: Typically 380V, 400V, 415V, or 460V depending on country

Frequency: 50 Hz or 60 Hz

Full Load Current (Approx): 14–16 Amps (varies by model & voltage)

Speed (RPM): Commonly available in 1500 RPM (4-pole) and 3000 RPM (2-pole) models

Efficiency Class: IE2 (High Efficiency), IE3 (Premium Efficiency), or IE4 (Super Premium Efficiency)

Frame Size: Varies (e.g., 132S/M) depending on manufacturer

Duty Cycle: S1 (Continuous duty) for industrial usage

Enclosure Type: TEFC (Totally Enclosed Fan Cooled) for dust protection

These specifications allow the motor to deliver steady mechanical performance while minimizing losses. For industries running 24/7, higher efficiency classes (IE3/IE4) are strongly recommended, as they cut down on operating costs significantly over time.

![ie3 and ie4 motor ie3 and ie4 motor]()

Advantages of Using 10 HP / 7.5 KW 3-Phase Motor

The 10 HP 3-phase motor offers several benefits over smaller single-phase motors and larger high-power motors:

Energy Efficiency

3-phase motors are inherently more efficient than single-phase motors.

Lower energy consumption reduces electricity costs.

High efficiency classes (IE3, IE4) further enhance performance.

Reliability & Durability

Built for continuous-duty operations (S1 duty).

Minimal vibrations ensure a longer lifespan.

TEFC enclosures protect from dust and moisture.

High Starting Torque

Smooth Operation

Lower Maintenance Costs

This combination of efficiency, durability, and smooth operation makes the 10 HP / 7.5 KW motor a smart investment for businesses seeking long-term productivity.

Applications of 10 HP / 7.5 KW 3-Phase Motor

The versatility of this motor makes it useful across multiple sectors:

Industrial Applications

Conveyors: Smoothly drives production line belts.

Compressors: Powers air and gas compressors.

Machine Tools: Operates lathes, drilling, and milling machines.

Fans & Blowers: Used in HVAC and industrial ventilation systems.

Commercial Applications

Workshops: Runs woodworking machines, polishing tools, and grinders.

Construction Sites: Powers concrete mixers, cutting tools, and pumps.

Agricultural Applications

Water Pumps: Irrigation and borewell pumps rely heavily on 10 HP motors.

Milling Machines: Used in rice mills, flour mills, and feed grinding.

Threshing & Processing: Drives agricultural processing equipment.

Its balanced size and power make the 10 HP motor a universal choice for small to medium industries and farms.

![Chain Conveyor Systems Chain Conveyor Systems]()

Types of 3-Phase Motors in the 10 HP / 7.5 KW Range

There are different types of motors available in this power rating, each suited to different applications:

1. Squirrel Cage Induction Motor

Most common type.

Rugged, simple, and requires little maintenance.

Best for general-purpose applications (fans, pumps, conveyors).

2. Slip-Ring Induction Motor

Provides higher starting torque.

More expensive, with additional maintenance requirements.

Useful for heavy-load start applications (crushers, elevators).

3. Synchronous Motor

Runs at a constant speed regardless of load.

High efficiency and power factor correction benefits.

Suitable for applications requiring precise speed control.

Each motor type has its advantages, but for most users, a squirrel cage induction motor offers the best balance of performance and affordability.

Installation Guidelines for 10 HP / 7.5 KW 3-Phase Motor

Proper installation is critical for ensuring long life and optimal performance of a 3-phase motor. A poorly installed motor may suffer from vibration, overheating, and premature failure.

1. Foundation and Mounting

Place the motor on a solid, vibration-free foundation.

Use proper mounting bolts to avoid misalignment.

For heavy machinery, ensure anti-vibration pads are installed.

2. Alignment

3. Electrical Connections

Always confirm the supply voltage matches the motor’s rated voltage (380V, 400V, 415V, or 460V).

Connect cables securely using appropriate lugs and terminals.

Follow the wiring diagram provided by the manufacturer.

4. Cooling and Ventilation

Ensure the motor is installed in a well-ventilated area.

Keep at least 30–50 cm clearance around the motor for air circulation.

For dusty environments, consider TEFC or IP55/IP65 enclosures.

5. Initial Testing

Measure insulation resistance before startup.

Run the motor without load first to check for unusual noises or overheating.

Gradually load the motor to full capacity after successful testing.

A carefully planned installation not only improves performance but also reduces downtime and maintenance costs.

![3 phase motor 3 phase motor]()

Maintenance Tips for 10 HP / 7.5 KW 3-Phase Motor

A preventive maintenance plan extends the life of a motor significantly. While these motors are robust, they still require routine checks.

1. Lubrication

Bearings should be greased as per the manufacturer’s recommendation.

Over-greasing can cause overheating, while under-greasing leads to wear.

2. Electrical Inspections

Check for loose connections in terminal boxes.

Inspect for insulation damage in cables.

Perform megger testing periodically.

3. Cooling System Maintenance

4. Vibration Monitoring

5. Regular Load Checks

With proper care, a 10 HP motor can easily last 10–15 years or more in continuous service.

Buying Guide for 10 HP / 7.5 KW 3-Phase Motor

Before purchasing a motor, businesses must evaluate multiple factors to ensure they’re making a cost-effective decision.

1. Define Your Requirements

Application type: Pumps, compressors, fans, or conveyors.

Duty cycle: Continuous or intermittent usage.

Environment: Clean, dusty, or wet conditions.

2. Efficiency Class

IE2: Basic efficiency (lower upfront cost).

IE3: Premium efficiency (recommended for most industries).

IE4: Super premium efficiency (higher upfront, but big savings long-term).

3. Starting Method

DOL (Direct On-Line): Simple but high inrush current.

Star-Delta Starter: Reduces starting current.

Soft Starter/VFD: Best for smooth startup and speed control.

4. Brand and Service Availability

Choose brands with local support and spare parts availability.

Consider both premium brands (ABB, Siemens, WEG) and reliable underdogs (Victory-Motor).

5. Cost vs. Long-Term Savings

By considering these aspects, you can make a smart, long-term investment in the right motor.

![yongzhuan&victory motor yongzhuan&victory motor]()

Top Brands of 10 HP / 7.5 KW 3-Phase Motors

Here are some leading motor manufacturers that offer reliable 10 HP 3-phase motors:

Siemens – Known for advanced technology and premium efficiency designs.

ABB – Offers robust motors with excellent global service support.

WEG – A popular choice for high-performance motors at competitive prices.

Toshiba – Heavy-duty motors for industrial-grade applications.

Baldor (A member of ABB) – High-efficiency motors, widely used in North America.

Crompton Greaves (CG Power) – Affordable and reliable options in Asia.

Teco-Westinghouse – Trusted in heavy industries worldwide.

Havells – Known for durable motors in commercial and agricultural use.

Victory-Motor – A reliable underdog, offering cost-effective 3-phase motors with growing market presence.

Nidec – Specializes in energy-efficient motor solutions with advanced designs.

Each brand has its strengths—premium manufacturers focus on cutting-edge efficiency, while others like Victory-Motor provide affordability with reliability.

Future Trends in 10 HP / 7.5 KW 3-Phase Motors

The motor industry is evolving, and the future of 10 HP motors will be shaped by several key trends:

Energy Efficiency Regulations

Integration with IoT

Variable Frequency Drive (VFD) Adoption

Sustainable Manufacturing

Compact & Lightweight Designs

The 10 HP / 7.5 KW motor will remain one of the most widely used industrial machines, but it will continue to improve in efficiency, connectivity, and durability.

![iec motor iec motor]()

Cost Considerations of a 10 HP / 7.5 KW 3-Phase Motor

The price of a 10 HP / 7.5 KW 3-phase motor can vary depending on brand, efficiency class, and features.

Standard IE2 models: $500 – $800

Premium IE3 models: $800 – $1,200

Super Premium IE4 models: $1,200 – $1,600+

Additional costs may include:

Starter/Drive Systems (Star-Delta Starter or VFD): $200 – $700

Installation and Wiring: Depending on site complexity, costs can range from $150 – $400.

Maintenance: Routine lubrication and inspections are relatively low-cost compared to unexpected breakdowns.

Pro Tip: Instead of focusing only on initial cost, businesses should calculate the lifetime cost of ownership (LCO). A slightly more expensive IE3 or IE4 motor can pay for itself within 1–2 years by saving on electricity bills.

Comparison: 10 HP / 7.5 KW 3-Phase Motor vs Other Ratings

To understand the value of a 10 HP motor, let’s compare it with smaller and larger options:

| Motor Rating | Power (KW) | Common Use Cases | Pros | Cons |

| 5 HP | 3.7 KW | Small workshops, light-duty pumps | Lower cost, compact | Limited load capacity |

| 10 HP | 7.5 KW | Industrial pumps, compressors, conveyors | Balanced power & size, versatile | Mid-level cost |

| 20 HP | 15 KW | Large factories, heavy-duty fans, big mills | Handles larger loads | Higher initial cost, more space needed |

The 10 HP motor strikes a balance—strong enough for industrial machinery but not oversized for smaller setups. It remains one of the most demanded ratings worldwide.

Energy Efficiency and Environmental Impact

Modern 10 HP / 7.5 KW 3-phase motors are designed to minimize energy waste, helping industries reduce both operational costs and carbon footprint.

IE3/IE4 Motors can save up to 15–25% energy compared to older IE1 models.

Reduced energy use translates directly into lower greenhouse gas emissions.

Motors with smart monitoring systems allow predictive maintenance, avoiding wasteful breakdowns.

By adopting high-efficiency motors, businesses not only comply with global energy regulations but also contribute to a more sustainable industrial future.

![Three-phase asynchronous motor and control panel Three-phase asynchronous motor and control panel]()

Conclusion

The 10 HP / 7.5 KW 3-phase motor is one of the most versatile and widely used industrial motors, striking the perfect balance between power, efficiency, and affordability.

Whether used in pumps, compressors, conveyors, fans, or agricultural machinery, it delivers reliable performance for years with minimal maintenance. Choosing the right motor requires considering efficiency class, brand, application, and total cost of ownership.

Brands like Siemens, ABB, WEG, and Baldor dominate the premium segment, while Victory-Motor is emerging as a reliable underdog, offering durable and cost-effective motors for growing businesses.

As industries move towards energy efficiency, IoT integration, and sustainability, the 10 HP motor will continue to evolve while maintaining its place as an industrial workhorse.

FAQs About 10 HP / 7.5 KW 3-Phase Motor

Q1. What is the full load current of a 10 HP 3-phase motor?

A 10 HP / 7.5 KW 3-phase motor typically draws 14–16 Amps, depending on the supply voltage and efficiency.

Q2. Can I run a 10 HP motor on single-phase power?

Directly, no. However, with a phase converter or VFD, a 3-phase motor can be adapted to run on single-phase supply.

Q3. Which efficiency class should I choose—IE2, IE3, or IE4?

For long-term savings, IE3 or IE4 motors are recommended, as they reduce energy bills significantly compared to IE2.

Q4. What starter is best for a 10 HP 3-phase motor?

DOL Starter: Cheapest, but high inrush current.

Star-Delta Starter: Good balance for reducing startup current.

VFD (Variable Frequency Drive): Best choice for smooth start and speed control.

Q5. How long can a 10 HP 3-phase motor last?

With proper maintenance, these motors can run for 10–15 years or more, even in continuous-duty applications.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी