![Aluminium Housing Induction Motor Aluminium Housing Induction Motor]()

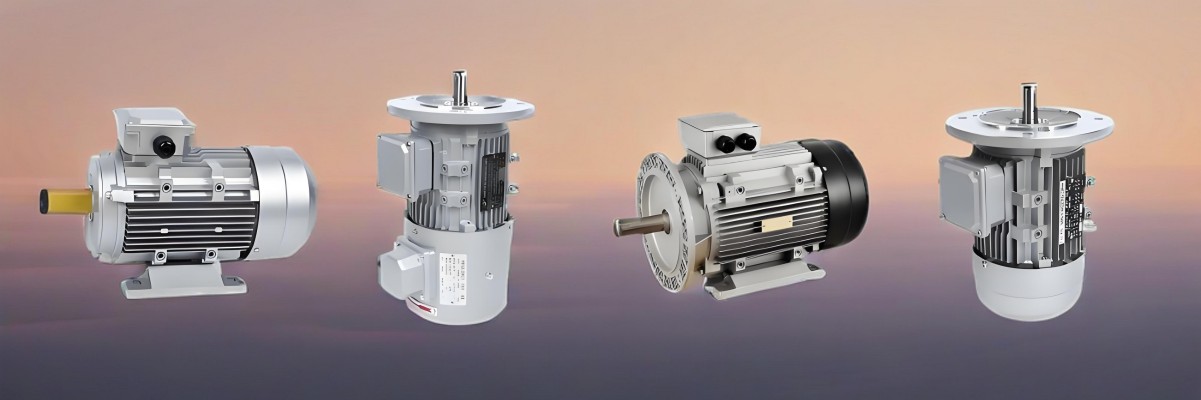

Aluminium Housing Induction Motor For Sales: Lightweight, Efficient, and Reliable Power

In the world of electric motors, the choice of housing material plays a crucial role in both performance and durability. Aluminium housing induction motors have become a popular choice across various industries due to their lightweight construction, excellent heat dissipation, and corrosion resistance. These motors are an ideal solution for applications requiring efficient power transmission, minimal maintenance, and a compact design.

Video of Yongzhuan Aluminium Housing Induction Motor

What is an Aluminium Housing Induction Motor (MS Series)?

An aluminium housing induction motor is a type of electric motor where the outer casing (or housing) is made from aluminium instead of traditional materials like cast iron or steel. The induction motor itself operates on the principle of electromagnetic induction, where current is induced in the rotor, causing it to rotate and generate mechanical power.

The aluminium housing serves multiple purposes, such as protecting the internal components of the motor, ensuring efficient cooling, and improving overall performance.

![What is an Aluminium Housing Induction Motor (MS Series) What is an Aluminium Housing Induction Motor (MS Series)]()

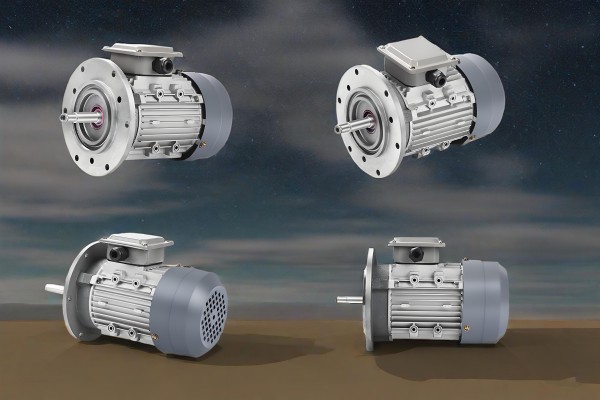

Key Features of Aluminium Housing Induction Motors (MS Series)

1. Lightweight Construction

One of the standout features of aluminium housing induction motors is their lightweight design. Aluminium is much lighter than cast iron or steel, making these motors easier to handle, transport, and install. This is particularly beneficial for applications where weight constraints are a concern, such as robotics and aerospace industries.

2. Excellent Heat Dissipation

Aluminium is known for its excellent thermal conductivity, meaning it can effectively dissipate heat generated by the motor’s operation. This feature helps keep the motor at optimal operating temperatures, reducing the risk of overheating and improving its overall efficiency and longevity.

3. Corrosion Resistance

Aluminium is naturally resistant to corrosion, which makes it an ideal material for motors used in humid or harsh environments. Whether the motor is exposed to moisture, salt, or chemicals, the aluminium housing helps prevent rust and ensures that the motor’s performance remains consistent over time.

4. High Strength-to-Weight Ratio

Despite being lightweight, aluminium housing induction motors offer a high strength-to-weight ratio, meaning they are both strong and durable. This allows them to withstand mechanical stresses and vibrations, ensuring a long service life.

5. Aesthetic Appeal

Aluminium’s sleek and modern appearance is often seen as an added benefit, particularly for applications where the motor is visible, such as in commercial appliances or consumer electronics.

![Key Features of Aluminium Housing Induction Motors Key Features of Aluminium Housing Induction Motors]()

Benefits of Aluminium Housing Induction Motors (MS Series)

1. Increased Energy Efficiency

Aluminium housing helps enhance the motor’s cooling ability, which reduces energy losses associated with excessive heat buildup. With better heat management, the motor operates more efficiently, delivering consistent performance and reducing energy consumption.

2. Reduced Weight for Easy Installation

The lightweight nature of these motors makes them easier to install, especially in tight spaces or complex systems. This feature reduces installation time and labor costs and can help streamline the setup of machines and equipment.

3. Durability and Long-Term Reliability

The combination of aluminium housing with induction motor technology results in a highly durable and reliable solution. The motor’s resistance to corrosion and its ability to withstand high temperatures and mechanical stresses mean that it can perform reliably for many years with minimal maintenance.

4. Cost-Effectiveness

Aluminium housing motors are generally more affordable than their cast iron counterparts. This, combined with their energy efficiency, makes them a cost-effective solution for both small and large-scale operations.

5. Environmental Friendliness

Aluminium is a recyclable material, making aluminium housing induction motors more eco-friendly compared to those made from non-recyclable materials. Additionally, the energy-saving benefits of these motors contribute to overall sustainability goals in industrial operations.

![Benefits of Aluminium Housing Induction Motors Benefits of Aluminium Housing Induction Motors]()

Applications of Aluminium Housing Induction Motors (MS Series)

Due to their versatility and robust performance, aluminium housing induction motors are widely used across multiple industries. Some of the key applications include:

1. HVAC Systems (Heating, Ventilation, and Air Conditioning)

Induction motors with aluminium housings are commonly used in HVAC systems due to their lightweight design and efficient cooling capabilities. They power fans, blowers, and compressors, ensuring that the system runs smoothly and maintains proper temperature control.

2. Pumps and Fans

Aluminium housing induction motors are frequently used in pumps and fans for applications such as:

✅Water supply systems

✅Cooling towers

✅Air circulation systems

Their efficient design helps these systems run effectively with minimal energy loss.

3. Conveyor Systems

In industries like logistics, automated warehousing, and food processing, induction motors are used to power conveyor belts and other automated systems. The lightweight nature and reliable performance of aluminium housing motors make them perfect for these continuous-duty applications.

4. Agricultural Machinery

Induction motors with aluminium housing are commonly used in agriculture for equipment like:

✅Irrigation pumps

✅Feed mixers

✅Grain dryers

Their durability, corrosion resistance, and energy efficiency make them an essential part of modern agricultural operations.

5. Industrial Machines

These motors are also used in various industrial machinery applications, such as:

✅Compressors

✅Centrifuges

✅Mixers

Their high torque and reliable performance are essential for industries that rely on heavy-duty machinery.

![Applications of Aluminium Housing Induction Motors Applications of Aluminium Housing Induction Motors]()

Parameter Sheet: Aluminium Housing Induction Motor

The Aluminium Housing Induction Motor is designed for a wide variety of industrial applications. Below is a detailed parameter sheet outlining the key specifications and features of the motor, providing you with all the necessary information to understand its capabilities and how it fits into different environments.

![]() Aluminium Housing Induction Motor Parameter Sheet.pdf

Aluminium Housing Induction Motor Parameter Sheet.pdf

General Specifications

| Parameter | Specification |

| Motor Type | Induction Motor |

| Housing Material | Aluminium Alloy |

| Efficiency Class | IE2 or IE3 (Energy Efficient) |

| Rated Power | 0.12 kW – 18.5 kW |

| Frequency | 50 Hz / 60 Hz |

| Rated Voltage | 220V / 380V / 415V / 690V / Customized |

| Rated Speed | 1500 RPM / 3000 RPM (depending on pole configuration) |

| Protection Class | IP55, IP56, IP65 (depending on specific motor model) |

| Cooling Method | IC411 (Continuous Operation, Self-Cooling) |

| Service Factor | 1.15 (Standard) |

| Ambient Temperature Range | -20°C to +40°C (can be adjusted based on specifications) |

| Mounting Type | Foot-mounted, Flange-mounted, Custom Mounting Options |

| Certifications | CE, UL, CSA, ISO9001 (varies by model and region) |

Electrical Specifications

| Parameter | Specification |

| Rated Power Factor | 0.85 - 0.95 |

| Rated Current | 0.25 A to 500 A (depending on motor size and rating) |

| Insulation Class | Class F / Class B (depending on motor size) |

| Voltage Tolerance | ±10% |

| Starting Method | Star-Delta, Direct-on-Line (DOL), Auto-transformer, Soft Start |

| Stator Resistance | 0.2 - 1.5 Ω (depending on motor size and type) |

| Rotor Resistance | 0.2 - 2.0 Ω (depending on motor size) |

| Winding Type | Copper winding (for optimal performance) |

| Motor Efficiency | ≥ 85% (IE3) or ≥ 75% (IE2) |

Mechanical Specifications

| Parameter | Specification |

| Frame Size | 80 – 355 mm |

| Shaft Diameter | Up to 150 mm (depending on motor power) |

| Shaft Length | Variable (based on mounting and configuration) |

| Bearing Type | Deep groove ball bearings or Roller Bearings (depending on model) |

| Noise Level | ≤ 75 dB(A) (varies by motor size and operating conditions) |

| Vibration | Grade 1 (ISO 10816) |

| Weight | Varies by model (ranging from 5 kg to 500 kg) |

Performance Characteristics

| Parameter | Specification |

| Torque | 1.5 - 2700 Nm (depending on motor size and rating) |

| Starting Torque | 150% to 250% of rated torque |

| Breakdown Torque | 200% to 250% of rated torque |

| Slip | 1 - 6% |

| Efficiency | Up to 96% (IE3) |

| Speed Tolerance | ±10% |

Enclosure and Cooling

| Parameter | Specification |

| Enclosure Type | Totally Enclosed Fan Cooled (TEFC) |

| Cooling Method | IC411 – Self Cooling (IC00 for low-power motors) |

| Protection Class | IP55 / IP56 / IP65 (standard options) |

| Corrosion Resistance | High (aluminium housing provides natural resistance) |

| Temperature Rise | 40°C Max (Class B), 80°C Max (Class F) |

Mounting Options

| Mounting Type | Specification |

| Foot-mounted (B3) | Standard base mounting with fixed bolts |

| Flange-mounted (B5) | Flange mounting with foot mounting (optional) |

| Face-mounted (B14) | Flange or face-mounted with optional torque arm |

| Custom Mounting (B35/B34) | Special mounting for specific applications |

Why Choose Aluminium Housing Induction Motors from Yongzhuan?

At Yongzhuan, we provide high-quality aluminium housing induction motors that offer the perfect balance of performance, durability, and efficiency. Here's why you should choose our motors for your industrial applications:

1. Superior Quality

Our motors are engineered using the latest technologies and high-grade materials, ensuring that they deliver long-lasting performance in a wide range of applications.

2. Energy-Efficient Design

Our aluminium housing induction motors are built to meet premium efficiency standards, helping you save on energy costs while reducing the environmental impact of your operations.

3. Customization Options

We offer a wide range of customization options to ensure that our motors meet your specific requirements. Whether you need a specific power rating, speed, or mounting configuration, we can provide a solution tailored to your needs.

4. Competitive Pricing

At Yongzhuan, we strive to offer affordable pricing without compromising on quality. Our aluminium housing induction motors provide exceptional value, ensuring you get the best performance for your investment.

5. Expert Support

Our team of experts is always available to provide guidance, whether you need help selecting the right motor or require after-sales support. We are committed to ensuring your complete satisfaction with our products.

![Why Choose Aluminium Housing Induction Motors from Yongzhuan Why Choose Aluminium Housing Induction Motors from Yongzhuan]()

FAQs of Aluminium Housing Induction Motor

1. What is the difference between aluminium housing and cast iron housing motors?

· Aluminium housing motors are lighter, more corrosion-resistant, and offer better heat dissipation compared to cast iron motors. They are ideal for applications requiring compact and efficient motors.

2. Are aluminium housing induction motors suitable for outdoor use?

· Yes, aluminium housing induction motors are resistant to moisture and corrosion, making them suitable for outdoor use, especially in harsh environments.

3. How can I ensure the longevity of an aluminium housing induction motor?

· Proper maintenance, including regular cleaning and inspection, as well as ensuring that the motor operates within recommended temperature ranges, will help extend its lifespan.

4. Can I use an aluminium housing induction motor in high-temperature environments?

· Yes, aluminium housing motors are designed to handle high temperatures and offer efficient cooling, making them suitable for a range of environments, including high-temperature settings.

5. Are aluminium housing induction motors energy-efficient?

· Yes, these motors are designed with premium efficiency (IE2, IE3), providing significant energy savings while delivering reliable performance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी