What is IE2 Electric Motors?

IE2 is an efficiency classification for electric motors as defined by the International Electrotechnical Commission (IEC). IE2 electric motors belong to the High-Efficiency Class of the IEC 60034-30 efficiency classification system. It stands for "International Efficiency Level 2," indicating motors with a medium level of energy efficiency.

![what are ie2 electric motors what are ie2 electric motors]()

Introduction

Electric motors play a vital role in powering industries worldwide, and energy efficiency has become a key focus in their development. Among various efficiency classifications, IE2 electric motors are widely used due to their balance of performance, cost, and compliance with international standards. If you're looking to improve energy usage without breaking the bank, Yongzhuan IE2 electric motors could be the perfect fit for your industrial applications.

Video of IE2 Electric Motors

IE2 Electric Motors vs. Other Efficiency Classes Motors

The International Efficiency (IE) classification system defines the efficiency levels of electric motors, helping industries make informed choices based on performance and energy-saving requirements. Here, we compare the four key efficiency classes motors: IE1 electric motors (Standard Efficiency), IE2 electric motors (High Efficiency), IE3 electric motors (Premium Efficiency), and IE4 electric motors (Super Premium Efficiency).

1. IE1 Electric Motors – Standard Efficiency Motors

Overview

IE1 electric motors are the basic standard-efficiency motors. They are still in use in some regions but are increasingly being phased out due to energy regulations.

Key Features

1. Efficiency Level: Lowest among the four classes.

2. Energy Consumption: High power consumption, leading to increased operational costs.

3. Applications: Suitable for simple, low-duty applications.

4. Compliance: Non-compliant with modern energy regulations like the EU Ecodesign Directive.

Best For:

1. Legacy systems.

2. Applications where efficiency is not critical and initial cost is the primary concern.

![IE1 ELECTRIC MOTORS IE1 ELECTRIC MOTORS]()

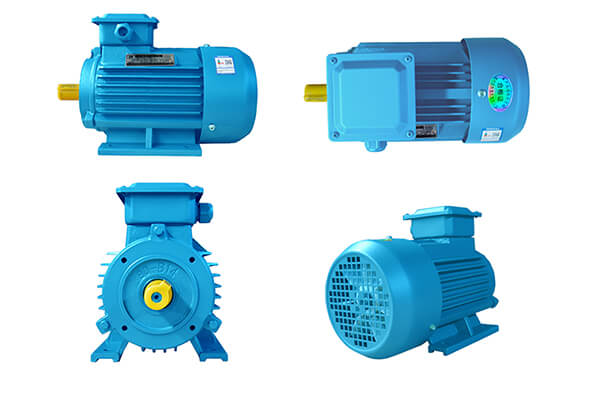

2. IE2 Electric Motors – High Efficiency Motors

Overview

IE2 electric motors offer improved energy efficiency and are the most commonly used motors in industries worldwide.

Key Features

1. Efficiency Level: Higher than IE1 electric motors, reducing energy consumption.

2. Energy Savings: Moderate energy savings compared to IE1 electric motors.

3. Applications: Widely used in industrial, commercial, and agricultural sectors.

4. Compliance: Meets global standards, including IEC 60034-30 and EU Ecodesign Directive for small and medium motors.

Best For:

1. Industries balancing cost and energy efficiency.

2. Applications like pumps, fans, compressors, and conveyors.

![ie2 electric motors ie2 electric motors]()

3. IE3 Electric Motors – Premium Efficiency Motors

Overview

IE3 electric motors deliver significantly higher energy savings and comply with stricter regulations worldwide.

Key Features

1. Efficiency Level: Up to 15% more efficient than IE2 electric motors.

2. Energy Savings: Substantial savings in energy-intensive operations.

3. Applications: Ideal for continuous or heavy-duty operations.

4. Compliance: Meets or exceeds modern regulations in most regions, such as the EU and North America.

Best For:

1. Facilities prioritizing energy efficiency.

2. Operations with high operating hours, where energy savings offset the higher initial cost.

![ie3 electric motors ie3 electric motors]()

4. IE4 Electric Motors – Super Premium Efficiency Motors

Overview

IE4 electric motors represent the highest level of efficiency available in standard electric motors, offering unparalleled performance for advanced energy-saving goals.

Key Features

1. Efficiency Level: Highest efficiency class, significantly exceeding IE3 levels.

2. Energy Savings: Maximum energy savings, ideal for reducing operational costs and carbon emissions.

3. Applications: Advanced industries, renewable energy projects, and green buildings.

4. Compliance: Fully compliant with future-ready energy efficiency regulations.

Best For:

1. Facilities aiming for sustainability and long-term energy savings.

2. High-performance systems where every watt saved matters.

![ie4 electric motors ie4 electric motors]()

Comparison Table: IE1 vs. IE2 vs. IE3 vs. IE4 Electric Motors

| Feature | IE1 (Standard) | IE2 (High Efficiency) | IE3 (Premium Efficiency) | IE4 (Super Premium Efficiency) |

| Efficiency Level | Low | Moderate | High | Very High |

| Energy Savings | Minimal | Moderate | Significant | Maximum |

| Initial Cost | Lowest | Moderate | Higher | Highest |

| Operational Costs | High | Moderate | Low | Lowest |

| Applications | Basic, low-demand tasks | Industrial, commercial | Heavy-duty, continuous use | Advanced, energy-critical systems |

| Regulatory Compliance | Limited (phasing out) | Meets modern standards | Meets strict global standards | Future-ready |

Advantages of IE2 Electric Motors

1. Reduced Energy Costs

IE2 Electric motors offer greater energy efficiency than IE1 motors, leading to lower power consumption and significant savings over the motor’s operational life. In Europe, the Ecodesign Directive (EU 640/2009) mandates the use of IE2 or higher-efficiency motors for certain applications, ensuring compliance with environmental policies.

2. Improved Durability and Longevity

Manufactured with precision engineering, these motors can withstand harsh operating conditions, minimizing the need for frequent maintenance.

3. Versatile Applications

IE2 Electric motors can be used in a variety of industries, from manufacturing and water management to HVAC and agriculture.

4. Environmentally Friendly

By consuming less energy, IE2 Electric motors reduce carbon emissions, contributing to sustainability efforts.

5. Cost-Effective Investment

Although IE2 Electric motors may have a slightly higher initial cost than IE1, their energy efficiency leads to significant savings in operating costs over the motor's lifespan. Meanwhile, Compared to premium-efficiency motors like IE3 and IE4, IE2 Electric motors offer a more affordable solution with a balanced performance-to-cost ratio.

![Advantages of IE2 Electric Motors Advantages of IE2 Electric Motors]()

Applications of IE2 Electric Motors

IE2 Electric motors are highly versatile and suited for a range of applications, including:

1. Industrial Applications

- Conveyor systems, crushers, and mixers.

- Compressors and material-handling equipment.

2. HVAC Systems

- Fans, blowers, and air conditioning units.

3. Water Management

- Pumps for irrigation, wastewater, and industrial water systems.

4. Agriculture

- Powering equipment like grain mills, threshers, and irrigation pumps.

5. Commercial Equipment

- Elevators, escalators, and industrial washing machines.

![Applications of IE2 Electric Motors Applications of IE2 Electric Motors]()

How to Choose the Right IE2 Electric Motors

Factors to Consider

Power Rating: Ensure the motor’s output matches the requirements of your application.

Voltage Compatibility: Check the compatibility with your electrical systems.

Environment: Consider the motor's ability to withstand harsh conditions like dust, moisture, or high temperatures.

Matching Motor Specifications to Applications

For example, a high-torque motor would be ideal for heavy machinery, while a compact motor may be better suited for HVAC systems.

Installation and Maintenance Tips for IE2 Electric Motors

Proper Installation Practices

Routine Maintenance Guidelines

Extending Motor Lifespan

Lubricate moving parts and monitor operating conditions to ensure the motor runs smoothly for years.

![Installation and Maintenance of ie2 electric motors Installation and Maintenance of ie2 electric motors]()

The Product Parameters of IE2 Electric Motors

![]() IE2 Electric motors Product Parameters .pdf

IE2 Electric motors Product Parameters .pdf

The Product Instructions of IE2 Electric Motors

![]() IE2 Electric motors Instruction Manual.pdf

IE2 Electric motors Instruction Manual.pdf

The Catalog of Yongzhuan Motor

![]() Product Catalogue-Yongzhuan Motor.pdf

Product Catalogue-Yongzhuan Motor.pdf

Plenty Stock of IE2 Electric Motors: Ready for Immediate Delivery

Looking for reliable, energy-efficient IE2 Electric motors? With plenty of stock available, we ensure a hassle-free supply for all your industrial, commercial, and residential applications. These motors are essential for powering a wide range of equipment and are known for their durability, efficiency, and excellent performance under various load conditions.

![Plenty Stock of IE2 Electric Motors Plenty Stock of IE2 Electric Motors]()

Why Choose Yongzhuan IE2 Electric Motors?

1. Fast Shipping and Delivery

With extensive inventory, we guarantee quick dispatch and delivery to meet your project timelines.

2. Expert Guidance

Our team of professionals is ready to assist you in choosing the right motor for your specific needs.

3. Customization Options

Need a custom configuration? We offer tailored solutions to suit unique application requirements.

4. Warranty and Support

All our motors come with comprehensive warranties and dedicated after-sales support.

5. Balanced Performance and Cost

Yongzhuan IE2 Electric motors strike a perfect balance between energy efficiency and affordability. They are an excellent choice for operations looking to reduce costs without investing in premium-efficiency motors.

6. Reliability in All Conditions

Yongzhuan IE2 Electric motors are built for durability and can handle continuous operations, even in challenging environments.

7. Faster ROI

With lower energy consumption and moderate pricing, Yongzhuan IE2 Electric motors deliver a quick return on investment through energy savings.

8. Standards and Compliance

Yongzhuan IE2 Electric motors comply with global energy efficiency regulations, ensuring reliability and performance. Standards include:

IEC 60034-30: Defines IE efficiency classes for electric motors.

Ecodesign Directive (EU): Ensures energy efficiency in European markets.

NEMA Compliance (USA): Aligns with high-efficiency standards in North America.

Comparison: Why Yongzhuan Stands Out

| Feature | Yongzhuan Motors | Competitor Brands |

| Energy Efficiency | IE2, IE3, IE4 options available | Limited availability of IE4 motors. |

| Durability | High-grade materials and robust design | Standard durability. |

| Pricing | Competitive with high value | Often higher for comparable models. |

| Customization | Flexible configurations available | Limited customization options. |

| Support and Warranty | Comprehensive and reliable | Basic customer support. |

![High Quality IE2 Electric motors High Quality IE2 Electric motors]()

Order Your High Quality IE2 Electric motors Today!

Don’t miss the chance to upgrade your systems with high quality IE2 Electric motors. Whether you need a motor for an industrial setup, an HVAC system, or a renewable energy project, we’ve got you covered.

Contact us today to explore our inventory and get a personalized quote. Optimize your operations with reliable and energy-efficient motors designed for the demands of the modern world!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी