Parallel Shaft Helical Gear Motor: The Ultimate Solution for Efficient Power Transmission

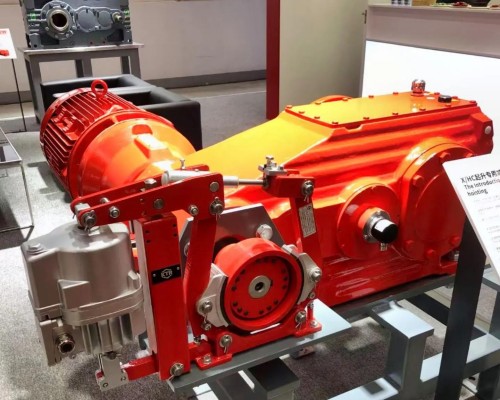

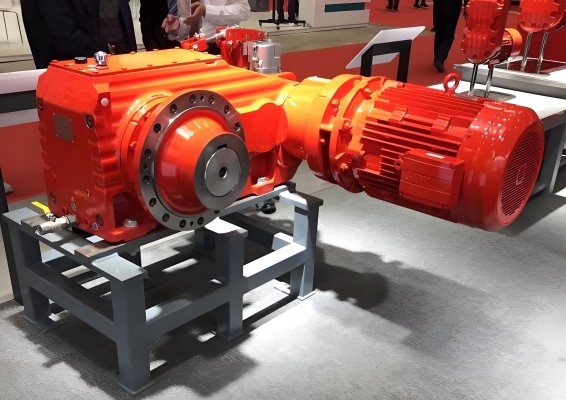

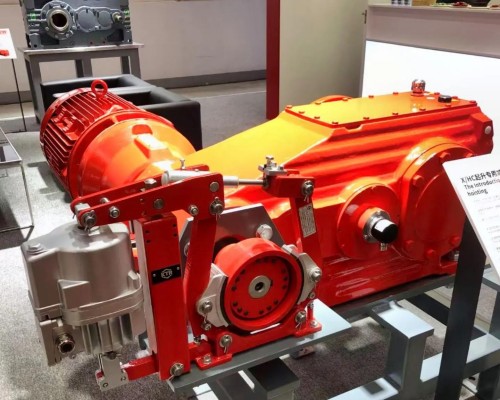

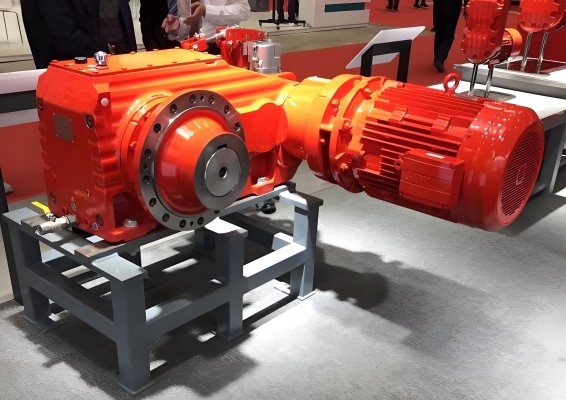

In the world of industrial machinery and automation, choosing the right gear motor is essential for optimal performance and energy efficiency. One such solution is the parallel shaft helical gear motor. Known for its compact design, high torque output, and efficiency, this gear motor is commonly used in industries like material handling, automation, agriculture, and more.

Video of Yongzhuan Parallel Shaft Helical Gear Motor

High Quality Parallel Shaft Helical Gear Motor For Sale

If you're looking for a reliable and efficient parallel shaft helical gear motor for your business, look no further than our top-of-the-line gear motor. Our parallel shaft helical gear motor for sale is designed to comply with standards of quality and efficiency, we're confident that it will meet all of your needs and exceed your expectations.

What is a Parallel Shaft Helical Gear Motor?

A parallel shaft helical gear motor is a type of gear motor that uses helical gears to transmit power between parallel shafts. Unlike traditional straight-cut gears, helical gears have teeth that are angled, allowing for smoother, quieter, and more efficient power transmission. These motors are particularly known for their compact design, high torque output, and low maintenance needs.

Key Benefits of Parallel Shaft Helical Gear Motors:

1. High Efficiency

Parallel shaft helical gear motors are known for their high efficiency. Thanks to the helical gears, which allow for a more gradual engagement of the teeth, they produce less friction and lower energy losses compared to traditional gears. This makes them an ideal choice for businesses looking to reduce operational costs.

2. Compact Design

One of the standout features of these gear motors is their compact design. The parallel shaft arrangement makes them perfect for applications where space is limited. The gear motor can be installed in tighter spaces while still delivering impressive power and torque.

3. Quiet Operation

Thanks to the angled teeth of the helical gears, parallel shaft helical gear motors operate much more quietly than other types of gear motors. This makes them suitable for noise-sensitive environments, such as laboratories, food processing plants, or commercial equipment.

4. High Torque and Load Capacity

Parallel shaft helical gear motors are designed to handle high torque and heavy loads, making them an excellent choice for applications that require consistent and reliable power transmission. The parallel shaft design helps distribute the load more evenly, increasing the motor’s load-bearing capacity.

5. Long Lifespan

Due to their precision engineering and quality materials, parallel shaft helical gear motors tend to have a longer lifespan compared to other types of gear motors. Their durable construction minimizes wear and tear, even under heavy loads and harsh conditions.

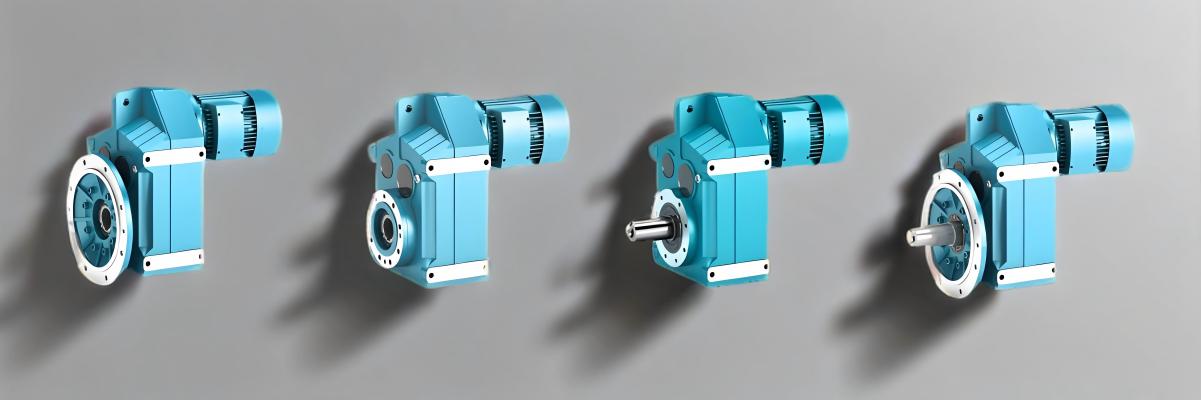

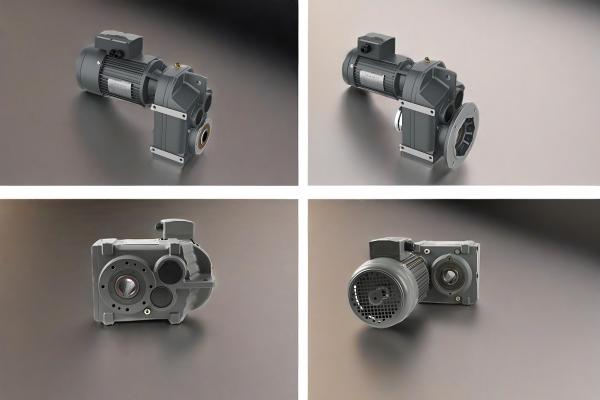

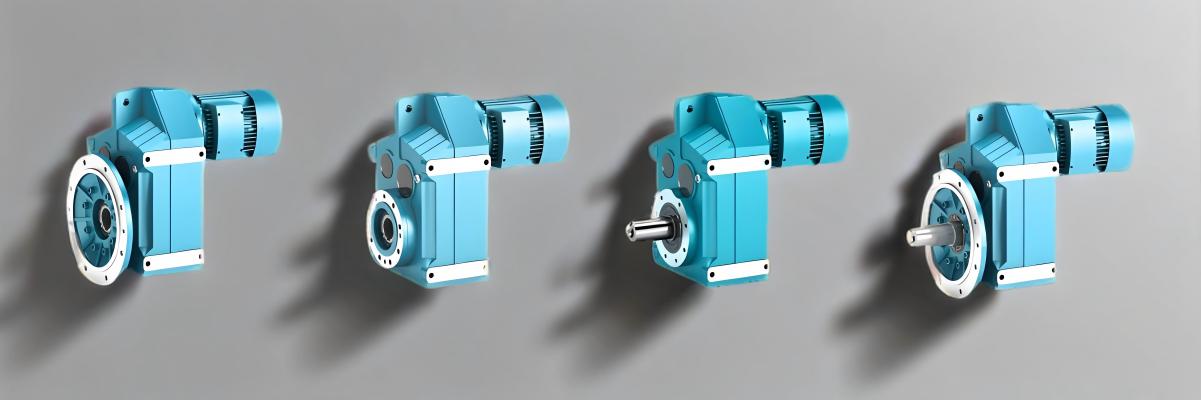

Types of Parallel Shaft Helical Gear Motors: F Series and Variants

In this part, we'll explore the different types of F Series Parallel Shaft Helical Gear Motors and explain how each variant is suited to specific applications and requirements. From solid shafts to hollow shafts and torque arms, understanding these options will help you choose the ideal gear motor for your needs.

1. F Series - Foot-Mounted, Solid Shaft Output

This is one of the most commonly used types of parallel shaft helical gear motors. The F Series with a foot-mounted, solid shaft output is ideal for applications where a rigid, stable mounting is required.

Features and Benefits:

✅Mounting: Foot-mounted for secure installation and ease of alignment.

✅Shaft Output: The solid shaft design is durable and provides stable power transmission.

✦Applications: Suitable for conveyor systems, material handling, and light-duty industrial machinery.

2. FAB Series - Foot-Mounted, Hollow Shaft Output

The FAB Series Parallel Shaft Helical Gear Motor combines the advantages of a foot-mounted motor with a hollow shaft output. This design allows for a more flexible coupling and makes it easier to integrate with other mechanical components. It’s particularly useful when compact space and easy installation are key considerations.

Features and Benefits:

✅Mounting: Foot-mounted for ease of installation.

✅Shaft Output: Hollow shaft offers better flexibility for coupling with shafts or other drive components.

✦Applications: Perfect for applications in conveyors, pumps, and robotic arms, where quick assembly and flexibility are necessary.

3. FA Series – Keyed Hollow Shaft Output

The FA Series Parallel Shaft Helical Gear Motor offers a keyed hollow shaft output, making it ideal for applications where mechanical connections require more secure locking. The keyed design ensures that there is no slippage between the motor and the driven shaft, making it perfect for heavy-duty applications.

Features and Benefits:

✅Mounting: Foot-mounted for secure and stable installation.

✅Shaft Output: Keyed hollow shaft ensures a strong and stable connection to the driven equipment.

✦Applications: Suitable for heavy-duty machinery, pumps, and agricultural machinery where a high level of reliability is essential.

4. FF Series – B5 Flange-Mounted, Solid Shaft Output

The FF Series Parallel Shaft Helical Gear Motor features a B5 flange-mounted design with a solid shaft output. Flange-mounted motors are ideal for situations where space-saving and alignment flexibility are crucial. The solid shaft provides a rigid and efficient connection, making it suitable for high-torque applications.

Features and Benefits:

✅Mounting: Flange-mounted for secure, compact installation.

✅Shaft Output: The solid shaft ensures a strong and reliable connection.

✦Applications: Ideal for industrial machinery, conveyors, and automated systems that require high torque and compact designs.

5. FAF Series – B5 Flange-Mounted, Hollow Shaft Output

The FAF Series Parallel Shaft Helical Gear Motor is a flange-mounted gear motor with a hollow shaft output. This design is highly adaptable, allowing for easy integration with various coupling systems. The hollow shaft provides more flexibility in connection, and the flange mount allows for efficient space utilization.

Features and Benefits:

✅Mounting: Flange-mounted for flexible installation.

✅Shaft Output: Hollow shaft for easy integration with other mechanical components.

✦Applications: Perfect for pumps, conveyor systems, and robotics requiring quick assembly and a flexible drive interface.

6. FAZ Series – B14 Flange-Mounted, Hollow Shaft Output

The FAZ Series features a B14 flange mount with a hollow shaft output. This variant is commonly used when specific mounting configurations are required, especially when there’s a need for a compact yet flexible solution. The B14 flange allows for more precise positioning and alignment.

Features and Benefits:

✅Mounting: B14 flange-mounted for precise and secure installation.

✅Shaft Output: Hollow shaft provides flexibility and ease of coupling.

✦Applications: Suitable for light to medium-duty machinery, conveyors, and material handling systems where compactness and flexibility are required.

7. FAT Series – Hollow Shaft Output, Torque Arm

The FAT Series Parallel Shaft Helical Gear Motor combines a hollow shaft output with a torque arm, offering additional support and stability to the system. The inclusion of the torque arm helps manage the loads on the motor more efficiently, especially in heavy-duty applications.

Features and Benefits:

✅Mounting: Includes a torque arm to manage additional loads and reduce stress on the system.

✅Shaft Output: Hollow shaft provides easy connection and alignment.

✦Applications: Ideal for heavy-duty equipment, agricultural machinery, and industrial conveyors.

8. FH, FHB, FHF, FHZ Series – Hollow Shaft Output, Shrink Disk

The FH Series and its variants (FHB, FHF, FHZ) Parallel Shaft Helical Gear Motor features a hollow shaft output with a shrink disk coupling. This allows for easy installation and secure coupling with the driven equipment. The shrink disk mechanism ensures that the shaft is locked tightly in place without the need for bolts or screws, making it easier to install and remove.

Features and Benefits:

✅Mounting: Hollow shaft with shrink disk coupling provides secure, easy assembly.

✦Applications: Perfect for high-speed machinery, automated systems, and material handling where quick maintenance and easy coupling are needed.

9. FV, FVB, FVF, FVZ Series – Hollow Shaft Output, Splined Hollow Shaft

The FV Series Parallel Shaft Helical Gear Motor offers a splined hollow shaft, which is ideal for transmitting high torques while allowing for precise positioning. The splined design ensures that the connection between the motor and driven equipment is both secure and flexible.

Features and Benefits:

✅Mounting: Hollow shaft with splined design for superior torque transmission.

✦Applications: Suitable for heavy-duty industrial equipment, automated systems, and conveyor systems requiring precise torque control.

10. F(SA, SF, FAF, FAB, FAZ)S Series – Solid Shaft Input

The F(SA, SF, FAF, FAB, FAZ)S Series Parallel Shaft Helical Gear Motor features a solid shaft input, offering flexibility in terms of how the motor is connected to the driving system. This configuration allows for easier integration with different types of input systems and is particularly useful for customized installations.

Features and Benefits:

Parameter Sheet of Parallel Shaft Helical Gear Motor

| F Series Reducer Parameters |

| Model | Solid ShaftDiameter(mm) | Hollow ShaftDiameter(mm) | Horizontal CentreHeight(mm) | Flange Cylindrical(mm) | Power(kw) | Speed Ratio | Permissible Torque(Nm) |

| F37 | 25 | 30 | 70 | 160 | 0.12~3 | 4~138 | 180 |

| F47 | 35 | 35 | 80 | 200 | 0.12~5.5 | 4~175 | 360 |

| F57 | 35 | 40 | 100 | 250 | 0.18~7.5 | 4~197 | 420 |

| F67 | 40 | 40 | 100 | 250 | 0.37~7.5 | 4~197 | 700 |

| F77 | 50 | 50 | 120 | 300 | 0.75~11 | 4~197 | 1350 |

| F87 | 60 | 60 | 155 | 350 | 1.5~22 | 4~193 | 2500 |

| F97 | 70 | 70 | 180 | 450 | 2.2~30 | 4~203 | 3700 |

| F107 | 90 | 90 | 200 | 450 | 3~45 | 4~205 | 6500 |

| F127 | 100 | 100 | 240 | 550 | 5.5~90 | 4~202 | 10000 |

| F157 | 120 | 120 | 270 | 660 | 11~160 | 4~190 | 18000 |

Parallel Shaft Helical Gear Motor Parameter Sheet.pdf

Parallel Shaft Helical Gear Motor Parameter Sheet.pdf

How To Choose Your Right Parallel Shaft Helical Gear Motor

1. Understand Your Application Needs

Before diving into the technical specifications, it's important to understand the specific needs of your application. The right parallel shaft helical gear motor will depend on several factors including:

✅Type of Load: Consider if your application is dynamic (with varying load demands) or static (consistent load).

✅Operating Environment: Are there any specific environmental factors like temperature, humidity, or exposure to chemicals that might affect the motor's performance? For example, in harsh environments, you may need a sealed motor or explosion-proof motor.

✅Duty Cycle: Will the motor be running continuously or intermittently? The duty cycle (continuous, short-time, or intermittent) will influence the power rating and operational limits.

By evaluating these aspects, you can narrow down the type of Parallel Shaft Helical Gear Motor that will work best for your setup.

2. Consider the Mounting Style

Parallel shaft helical gear motors come with various mounting configurations. The right mounting style affects installation ease, space-saving, and alignment. Here are the key options:

✅Foot-mounted motors: Common in many industrial applications, foot-mounted gear motors are easy to install and provide stable, vibration-free performance. These are ideal for applications where space is not a primary concern.

✅Flange-mounted motors: These motors are designed to be mounted with a flange, offering flexibility in alignment and positioning. Flange-mounted configurations are great for compact spaces or when space-saving is critical.

✅Torque-arm mounted motors: If you need additional support or need to eliminate stresses on the shaft, choosing a model with a torque arm (e.g., FAT Series) could be beneficial.

Carefully consider the available installation space and the preferred orientation of your system to choose the right mounting configuration.

3. Select the Correct Shaft Type

One of the main considerations when selecting a parallel shaft helical gear motor is the shaft configuration. The type of shaft affects the connection to your driven load and the flexibility of the coupling. Here are the key options to consider:

✅Solid Shaft: Provides a rigid connection to the load, offering more durability and reduced slippage. It's commonly used for heavier loads and industrial machinery.

✅Hollow Shaft: This option offers more flexibility for coupling to other components. It’s easier to integrate with other shafts and helps reduce assembly time.

✅Keyed Hollow Shaft: If you require a more secure connection and want to prevent shaft slippage, the keyed hollow shaft provides the necessary locking mechanism.

✅Splined Hollow Shaft: For applications requiring high torque transmission and flexibility in adjustments, the splined hollow shaft offers better control and torque stability.

Choose the type of shaft based on your application’s torque demands, load conditions, and coupling preferences.

4. Torque and Power Rating

Understanding the torque and power requirements of your system is essential for selecting the right motor size. This is especially true for high-torque applications like conveyor systems, mills, and other heavy-duty machinery. The torque rating of the motor should match or exceed the torque requirements of the application.

Considerations:

✅Torque Demand: Make sure that the gear motor you choose can handle the maximum torque expected from your application. Overloading the motor could lead to overheating or failure.

✅Power Rating: The power rating of the gear motor is usually given in kW (kilowatts) or HP (horsepower). The power rating should match the load requirements of your system. Ensure that the motor has a power rating that provides a safety margin for sudden load fluctuations.

It’s always better to slightly overshoot your torque and power requirements than to undershoot them, as this will give the motor more headroom for peak loads.

5. Gear Ratio Selection

The gear ratio determines how the motor speed is converted into output speed. For parallel shaft helical gear motors, the gear ratio affects both torque and speed. A higher gear ratio increases torque but reduces speed, while a lower gear ratio does the opposite.

Factors to consider:

✅Speed Requirements: If you need high-speed output, choose a motor with a lower gear ratio.

✅Torque Requirements: For high-torque applications, choose a motor with a higher gear ratio. This will provide more torque at lower speeds.

✅Precision and Adjustment: Some gear motors allow for fine-tuning of the gear ratio, giving you more control over your system’s performance.

Ensure that the gear ratio you select balances both speed and torque according to your system's needs.

Why Choose Yongzhuan Parallel Shaft Helical Gear Motor?

· Expert Consultation: Our technical experts provide personalized recommendations to help you choose the right gear motor for your application.

· Fast Delivery: We maintain a large inventory of Yongzhuan F Series Parallel Shaft Helical Gear Motor for quick turnaround times.

· Reliable After-Sales Support: Our dedicated customer service team offers support for installation, maintenance, and spare parts.

· Competitive Pricing: Get high-quality performance at an affordable price, making Yongzhuan a smart investment.

Comparison Table: Yongzhuan vs. Other Parallel Shaft Helical Gear Motors

| Feature | Yongzhuan Parallel Shaft Helical Gear Motor | Competitor A | Competitor B |

| Efficiency | High Efficiency (IE3/IE4) | Moderate (IE2) | High (IE3) |

| Energy Consumption | Low Power Consumption | Medium | High |

| Torque Output | High Torque, Maximized Performance | Moderate | Low |

| Noise Level | Ultra-Quiet Operation | Moderate Noise | High Noise |

| Vibration | Low Vibration | Moderate | High |

| Durability | High-Grade Steel, Long Lifespan | Standard Materials | Lower Durability |

| Maintenance | Low Maintenance, Sealed Bearings | Moderate Maintenance | Frequent Maintenance |

| Model Variations | Wide Range, Customizable | Limited Options | Limited Options |

| Cost | Cost-Effective, High Value | Expensive | Affordable, Lower Quality |

| Customer Service | Excellent Support | Standard Support | Limited Support |

FAQs of Parallel Shaft Helical Gear Motor

1. What makes parallel shaft helical gear motors better than other gear motors?

Parallel shaft helical gear motors offer higher efficiency, quieter operation, and greater torque capacity, making them ideal for demanding industrial applications.

2. How long do parallel shaft helical gear motors last?

With proper maintenance, these motors can last for several years due to their durable design and high-quality materials.

3. Can I customize the gear ratio of the motor?

Yes, we offer customized gear ratios to suit your specific speed and torque requirements.

4. Are these gear motors energy-efficient?

Absolutely! Our IE2 and IE3 rated gear motors are designed to minimize energy consumption and reduce operational costs.

5. Where can I buy parallel shaft helical gear motors?

You can purchase high-quality motors directly from Yongzhuan for competitive pricing and excellent customer service.