![Worm Gear Reducer Worm Gear Reducer]()

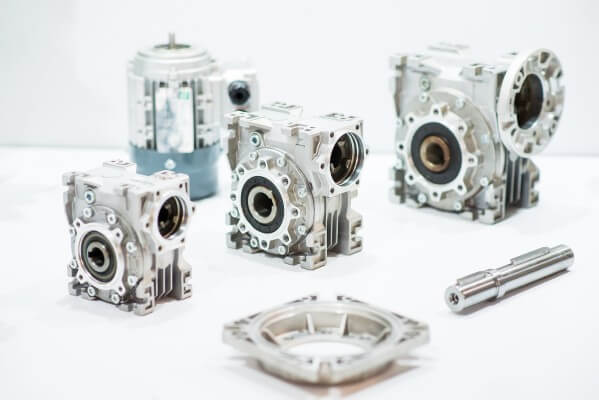

Worm Gear Reducer: Reliable and High-Quality Solutions

A worm gear reducer is a mechanical device designed to reduce rotational speed while increasing torque. It uses a worm (a threaded shaft) and a worm wheel (a toothed gear) to achieve this function. The worm meshes with the worm wheel, creating a system capable of handling high torque with minimal space requirements. A worm gear reducer, or worm gearbox, is the most commonly found speed reducer. Typically a worm gear reducer will be mounted or coupled to an electric motor. Worm gear reducers are available in a wide array of styles, configurations and ratio’s. Worm gear reducers are utilized in all industries, and come in sizes from a few pounds to several tons for heavy industrial applications.

Video of Yongzhuan Worm Gear Reducer

Worm Gear Reducer for Sales: Your One-stop Solution Expert

Looking for a reliable worm gear reducer for sale? Whether you're upgrading your machinery or starting a new project, worm gear reducers are an ideal solution for applications requiring high torque and precise motion control. Compact, durable, and versatile, these reducers are widely used in industrial, agricultural, and automotive applications.

In this article, we’ll guide you through everything you need to know about worm gear reducers, their benefits, applications, and how to choose the right one for your needs.

![Worm Gear Reducer for Sales Your One-stop Solution Expert Worm Gear Reducer for Sales Your One-stop Solution Expert]()

Types of Worm Gear Reducer

4 Types of Worm Gear Reducer Based on Reduction Stages

Worm gear reducers are classified based on the number of reduction stages used to achieve the desired speed reduction. Each stage consists of a worm and worm wheel, and adding more stages increases the reduction ratio while decreasing the output speed. Below are the main types based on reduction stages:

1. Single-Stage Worm Gear Reducer

A single-stage worm gear reducer consists of one worm gear set (a worm shaft and a worm wheel), offering a moderate reduction ratio.

· Features:

✔️ Compact and lightweight

✔️ High efficiency with minimal power loss

✔️ Simple design and easy maintenance

✔️ Reduction ratio typically ranges from 5:1 to 100:1

· Common Applications:

Conveyor belts

Fans and blowers

Pumps and agitators

![Single-Stage Worm Gear Reducer Single-Stage Worm Gear Reducer]()

2. Double-Stage Worm Gear Reducer

A double-stage worm gear reducer includes two worm gear sets, allowing for a higher reduction ratio while maintaining smooth operation.

· Features:

✔️ Achieves much lower output speeds

✔️ Increases torque output significantly

✔️ Moderate efficiency compared to a single-stage design

✔️ Reduction ratio typically ranges from 100:1 to 300:1

· Common Applications:

Lifting equipment

Hoists and elevators

Automated industrial machinery

![Double-Stage Worm Gear Reducer Double-Stage Worm Gear Reducer]()

3. Multi-Stage Worm Gear Reducer

A multi-stage worm gear reducer features three or more worm gear sets, designed for applications that require ultra-high reduction ratios and precise motion control.

· Features:

✔️ Provides extremely low output speeds

✔️ Delivers massive torque for heavy-duty applications

✔️ Increased mechanical complexity with lower efficiency

✔️ Reduction ratio often exceeds 300:1, reaching up to 1000:1 or more

· Common Applications:

Mining and drilling machinery

Robotics and automation systems

Industrial presses and material processing equipment

![Multi-Stage Worm Gear Reducer Multi-Stage Worm Gear Reducer]()

4. Compound Worm Gear Reducer

A compound worm gear reducer combines worm gears with other gear types (such as helical or planetary gears) to improve efficiency and achieve high reduction ratios with less power loss.

· Features:

✔️ Increased efficiency compared to pure worm gear designs

✔️ Compact size with high reduction capabilities

✔️ Suitable for applications requiring both speed control and torque multiplication

· Common Applications:

High-precision machine tools

Aerospace and defense systems

Large-scale material handling

![Compound Worm Gear Reducer Compound Worm Gear Reducer]()

6 Types of Worm Gear Reducers Based on Input method and Flange

Worm gear reducers can be classified based on their input method and flange type, which determines how the motor or power source connects to the gearbox. Choosing the right input method ensures efficient power transmission, compatibility, and ease of installation. Below are the main types based on input method and flange design:

1. Direct Motor Input Worm Gear Reducer

This type of worm gear reducer has a pre-integrated motor flange, allowing the motor to be directly attached without additional couplings.

· Features:

✔️ Compact and space-saving design

✔️ Reduces alignment issues

✔️ Ensures efficient power transmission

· Common Applications:

Electric motors in conveyors

Small automation systems

Pumps and fans

![Direct Motor Input Worm Gear Reducer Direct Motor Input Worm Gear Reducer]()

2. Coupling Input Worm Gear Reducer

This type of worm gear reducer uses a coupling or flexible connection between the motor and the reducer, allowing compatibility with different motor types.

· Features:

✔️ Allows flexibility in motor selection

✔️ Absorbs misalignment and vibrations

✔️ Reduces mechanical stress on components

· Common Applications:

Heavy-duty machinery

Industrial automation

Material handling equipment

3. Shaft Input Worm Gear Reducer

In this design, the power input is transferred through a solid input shaft, which can be connected to an external motor using belts or gears.

· Features:

✔️ Allows multiple power input options

✔️ Ideal for customized drive systems

✔️ High durability for industrial use

· Common Applications:

Belt-driven systems

Large agricultural equipment

Processing machines

4. B5 Flange Worm Gear Reducer

A B5 flange worm gear reducer has a large, round flange with multiple mounting holes for direct motor installation.

· Features:

✔️ Standardized for easy motor attachment

✔️ Ensures stable and vibration-free operation

✔️ Ideal for high-precision applications

· Common Applications:

Servo and stepper motor applications

CNC machinery

Automated conveyor systems

5. B14 Flange Worm Gear Reducer

A B14 flange worm gear reducer has a smaller, compact flange, making it suitable for lightweight and space-constrained applications.

· Features:

✔️ Compact and lightweight design

✔️ Suitable for smaller motors

✔️ Used in limited-space environments

· Common Applications:

Textile machinery

Small pumps and fans

Food processing equipment

6. Customized Flange Worm Gear Reducer

Some worm gear reducers have custom flange designs, allowing for unique mounting and motor connection requirements.

· Features:

✔️ Tailored for specific applications

✔️ Allows integration with specialized motors

✔️ Enhances system efficiency and stability

· Common Applications:

Robotics and automation

High-speed industrial machinery

Custom-built mechanical systems

![Customized Flange Worm Gear Reducer Customized Flange Worm Gear Reducer]()

The Parameter Sheet of Yongzhuan Worm Gear Reducer

![]() Worm Gear Reducer Parameter Sheet.pdf

Worm Gear Reducer Parameter Sheet.pdf

Benefits of Worm Gear Reducer

1. High Torque Output

Worm gear reducers provide excellent torque multiplication, allowing machines to handle heavy loads efficiently.

✅ Ideal for high-load applications

✅ Ensures consistent power transmission

✅ Reduces stress on motor and mechanical parts

Used in: Lifting equipment, conveyors, crushers

2. Compact and Space-Saving Design

The right-angle design of worm gear reducers allows for space-efficient installations, making them ideal for tight spaces.

✅ Requires less installation space

✅ Ideal for compact machinery designs

✅ Allows flexible mounting positions

Used in: Robotics, material handling, packaging machines

3. High Gear Reduction Ratio

Worm gear reducers can achieve large speed reductions with a single gear stage, reducing complexity in machine design.

✅ Eliminates the need for multiple gear stages

✅ Provides smooth and stable operation

✅ Reduces motor speed efficiently

Used in: Conveyor belts, mixers, pumps

4. Quiet and Smooth Operation

The sliding motion of worm gears results in low noise and minimal vibration, making them ideal for applications requiring quiet operation.

✅ Reduces machine noise and disturbances

✅ Minimizes vibrations, increasing component life

✅ Ideal for indoor and precision applications

Used in: Medical equipment, elevators, food processing machines

5. High Durability and Low Maintenance

Worm gear reducers have fewer moving parts, leading to lower wear and tear, resulting in longer service life.

✅ Made from wear-resistant materials

✅ Requires minimal lubrication

✅ Handles harsh environments effectively

Used in: Outdoor conveyors, mining equipment, agricultural machinery

6. Self-Locking Feature for Safety

The unique design of worm gear reducers allows them to be self-locking, meaning the output shaft cannot back-drive the system.

✅ Prevents machine back-driving

✅ Enhances safety in lifting applications

✅ Reduces the need for additional braking mechanisms

Used in: Hoists, cranes, automation systems

7. Energy Efficiency and Cost Savings

Worm gear reducers help in reducing energy consumption by ensuring smooth and efficient power transmission.

✅ Minimizes power losses

✅ Improves operational efficiency

✅ Reduces electricity and maintenance costs

Used in: HVAC systems, conveyors, industrial fans

![Benefits of Worm Gear Reducer Benefits of Worm Gear Reducer]()

How to Select Your Right Worm Gear Reducer

1. Determine the Required Gear Ratio

The gear ratio defines how much the worm gear will reduce the input speed to achieve the desired output speed. A higher gear ratio provides a greater reduction in speed but can result in higher heat generation and lower efficiency.

Consider:

✔️ The desired speed reduction

✔️ The torque needed for your application

✔️ The output speed required for optimal performance

Example: If your application requires reducing a motor speed of 1500 RPM to 50 RPM, the gear ratio would be 30:1.

2. Calculate the Load and Torque Requirements

The load and torque dictate the size and type of worm gear reducer needed. Be sure to evaluate both dynamic loads (loads in motion) and static loads (loads at rest).

Consider:

✔️ The magnitude of the load the reducer must handle

✔️ The torque at the output shaft

✔️ The impact of shock loading on the gear reducer

Example: For heavy-duty applications like lifting systems or conveyors, a high-torque worm gear reducer would be necessary.

3. Consider the Available Space

The installation space plays a significant role in selecting the right worm gear reducer. Compact designs are ideal for space-constrained environments, whereas larger units may be needed for heavier, more powerful applications.

Consider:

✔️ The available installation space

✔️ The physical size of the reducer

✔️ Whether the reducer needs to be installed in a specific orientation

Example: For tight spaces or compact machinery, opt for a shaft-mounted or flange-mounted worm gear reducer.

4. Choose the Correct Mounting Type

The mounting style of the worm gear reducer must match your system's design and mounting requirements. Common mounting options include foot-mounted, flange-mounted, or shaft-mounted types.

Consider:

✔️ How the reducer will be mounted on your equipment

✔️ The orientation of the input and output shafts

✔️ The ease of installation and maintenance

Example: A foot-mounted reducer is suitable for stationary applications, while a shaft-mounted option works well for more compact or mobile systems.

5. Check the Efficiency and Heat Dissipation

Energy efficiency is important for minimizing operating costs, while heat dissipation ensures the worm gear reducer doesn't overheat under load. Look for reducers with low friction and smooth operation for better efficiency.

Consider:

✔️ The efficiency rating of the worm gear reducer

✔️ Whether the reducer can handle the operating temperature

✔️ The need for cooling systems or additional lubrication

Example: For continuous operations, choose a reducer with a high-efficiency rating and good heat dissipation properties.

6. Select the Appropriate Material and Construction

The material of the worm gear and housing affects the durability and performance of the worm gear reducer. Alloy steel or bronze are often used for their strength and wear resistance.

Consider:

✔️ The environment in which the reducer will operate (e.g., harsh or humid environments)

✔️ The material strength required for your application

✔️ The need for corrosion resistance

Example: For applications in corrosive or extreme conditions, consider stainless steel or corrosion-resistant materials.

![How to Select Your Right Worm Gear Reducer How to Select Your Right Worm Gear Reducer]()

Why Choose Yongzhuan Worm Gear Reducer

When selecting a worm gear reducer for your industrial applications, it is essential to make an informed choice based on key features such as efficiency, reliability, and performance. Among the numerous options available in the market, Yongzhuan worm gear reducers stand out for their superior quality, advanced technology, and cost-effectiveness.

1. Fast Shipping and Delivery

With extensive inventory, we guarantee quick dispatch and delivery to meet your project timelines.

2. Expert Guidance

Our team of professionals is ready to assist you in choosing the right worm gear reducer for your specific needs.

3. Customization Options

Need a custom configuration? We offer tailored solutions to suit unique application requirements.

4. Warranty and Support

All our worm gear reducer come with comprehensive warranties and dedicated after-sales support.

5. Competitive Pricing

Yongzhuan offers high-quality worm gear reducer at competitive prices, ensuring you get the best value for your investment. With our reducers offering a blend of quality, efficiency, and affordable pricing, you can achieve excellent performance without exceeding your budget.

6. Superior Quality and Durable Long Life

The high-quality parts, carefully chosen components and advanced manufacturing techniques ensure that each worm gear reducer meets strict quality standards, providing exceptional performance, extending operational life and reducing maintenance costs.

Comparison: Yongzhuan vs. Other Worm Gear Reducers

| Feature | Yongzhuan Worm Gear Reducers | Competitor Brands |

| High Efficiency and Energy Savings | Low friction and optimized tooth geometry, leading to higher efficiency | Higher friction and energy losses |

| Durability and Longevity | Advanced surface treatments and high-wear resistance | Wear faster materials |

| Compact Design and Easy Installation | Compact and flexible designs, shaft-mounted and flange-mounted options for easy integration | Fewer mounting options, Bulkier and less flexible |

| Noise and Vibration Levels | Precision engineering and smooth components ensure that reducers operate quietly | Tend to produce more noise and vibration, especially during prolonged usage |

| Customization and Flexibility | Highly customizable options | May not meet unique application requirements. |

| Wide Range of Applications | Designed to handle varied loads and environmental conditions. | Specialize in specific industries |

![Why Choose Yongzhuan Worm Gear Reducer Why Choose Yongzhuan Worm Gear Reducer]()

FAQs of Yongzhuan Worm Gear Reducer

1. What is the primary function of a worm gear reducer?

It reduces speed and increases torque, making it essential for various mechanical systems.

2. How do I determine the right size of a worm gear reducer for my application?

By calculating the load, torque, and speed reduction requirements specific to your use case.

3. What materials are commonly used in worm gear reducers?

Aluminum, bronze, and cast iron are popular choices for durability and performance.

4. Are worm gear reducers suitable for heavy-duty applications?

Yes, especially models designed with high torque capabilities.

5. What are the advantages of buying from a one-stop service provider?

Convenience, expert guidance, comprehensive product range, and reliable after-sales support.

Why Wait? Get Your Worm Gear Reducer Today!

Yongzhuan Worm Gear Reducers offer unparalleled efficiency, precision, and durability across a variety of applications. If you have more questions or need assistance selecting the right reducer, reach out to our team today! Let us help you optimize your operations with our reliable solutions.

Product Catalog of Yongzhuan Motor

![]() Product Catalogue-Yongzhuan Motor.pdf

Product Catalogue-Yongzhuan Motor.pdf

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी