Introduction to 0.75 HP / 0.55 KW 3-Phase Motors

A 0.75 HP (horsepower) or 0.55 kW 3-phase motor is one of the most widely used industrial motors due to its balance of power, efficiency, and compact size. It’s powerful enough to drive essential equipment while consuming minimal electricity, making it a favorite in workshops, factories, and even agricultural settings.

What Does 0.75 HP Mean?

Horsepower is a traditional unit of power. 0.75 HP indicates that the motor can deliver three-quarters of a horsepower, which is strong enough for small to medium industrial jobs.

Understanding Kilowatt Conversion

Kilowatt (kW) is the modern unit of power.

1 HP = 0.746 kW, so 0.75 HP equals approximately 0.55 kW — making both terms interchangeable when describing this motor.

Why 3-Phase Motors Are Preferred

3-phase motors are popular because they:

They are widely used in commercial and industrial applications where reliability is crucial.

![Dual-Voltage Motors Dual-Voltage Motors]()

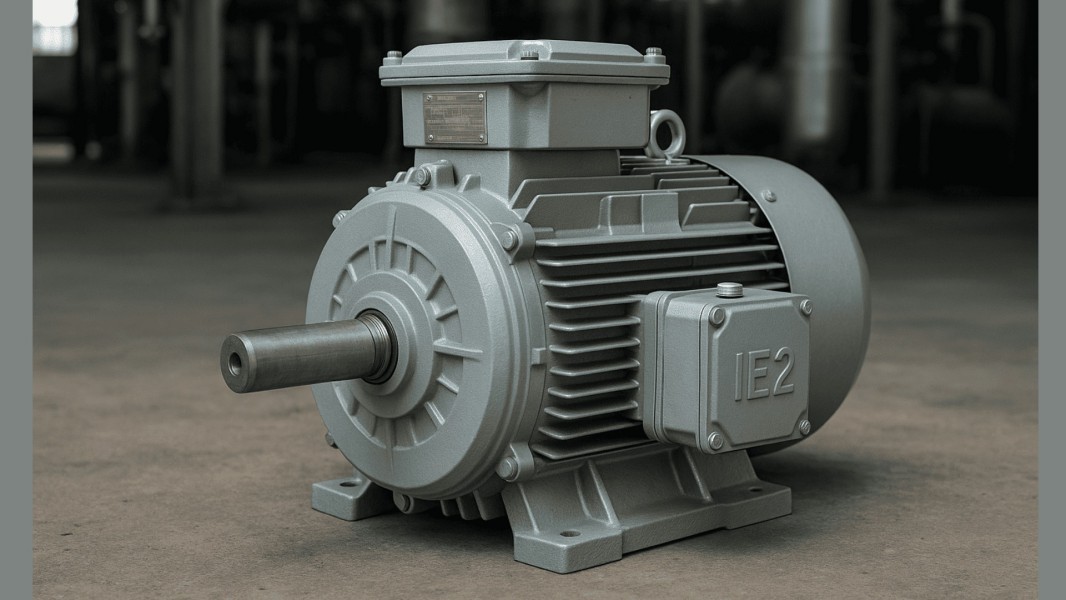

Key Technical Specifications

1. Output Power and Efficiency

A 0.75 HP motor delivers stable power output while maintaining excellent energy efficiency. Many modern models also meet IE2 or IE3 efficiency standards for lower energy costs.

2. Voltage and Frequency Ratings

Typical ratings include:

3. RPM and Speed Options

Common speed ratings for this motor are:

At 50HZ:

750 RPM

1000 RPM

1500 RPM

3000 RPM

At 60HZ:

900 RPM

1200 RPM

1800 RPM

3600 RPM

The speed depends on the number of poles in the motor.

4. Frame Size and Mounting Types

Standard frame sizes include 71, 80, or 90 frames.

Mounting options:

Foot-mounted (B3)

Flange-mounted (B5)

Foot & Flange (B35)

5. Wiring Methods of 3-Phase Motor

Here’s a clear explanation of the two three-phase motor wiring methods:

Star (Y) Connection

· Wiring Setup: The motor’s three winding ends (U2, V2, W2) are connected together (forming a "star" center point), while the three start ends (U1, V1, W1) connect to the three-phase power supply.

· Key Electrical Traits: Line voltage (power supply voltage) is √3x winding voltage; line current equals winding current.

· Common Use Case: Used for motors designed for high-voltage input (e.g., 380V supply with 220V windings) or to reduce startup current (e.g., in light-load applications like fans or small pumps).

Delta (△) Connection

· Wiring Setup: The motor’s winding ends are connected in a closed loop: U2 to V1, V2 to W1, W2 to U1. The three-phase power supply connects to the junction points (U1, V1, W1).

· Key Electrical Traits: Line voltage equals winding voltage; line current is √3x winding current.

· Common Use Case: Used for motors designed for low-voltage input (e.g., 220V supply with 220V windings) or high-torque applications (e.g., compressors, conveyors, heavy machinery).

![Wiring Methods Wiring Methods]()

6. Site conditions

Motors operate reliably in most industrial environments with temperatures ranging from -15°C to +40°C (ideal for warehouses, factories, and outdoor shelters) and at altitudes below 1000 meters (compatible with low-to-moderate elevation facilities like urban plants or rural workshops). This versatility makes them suitable for global applications in non-extreme climates.

7. Insulation

The motor’s insulation system meets Class F (105K) performance standards (rated for high-temperature endurance) and is validated via Class B (80K) testing—ensuring extended lifespan (up to 20,000+ operating hours) and consistent reliability in continuous-duty scenarios (e.g., 24/7 machinery). This dual-class compliance reduces downtime for critical equipment.

8. Motor protection

For enhanced safety and maintenance, motors can be customized with PTC thermistors or PT100 temperature sensors (on request) to monitor winding and bearing heat. These components trigger alerts or shutdowns during overheating, preventing damage in high-load applications (like compressors or conveyors) and lowering repair costs.

9. Vibration

Motors are engineered to Vibration Class A (low noise and minimal mechanical wear), ideal for precision equipment (like packaging machines or medical tools). For specialized needs (e.g., quiet environments or sensitive instrumentation), Vibration Class B (even smoother operation) can be requested.

10. Duty

Designed for Continuous Duty (S1) operation—meaning the motor runs indefinitely at rated load without overheating. This makes it perfect for 24/7 applications: industrial pumps, ventilation fans, conveyor systems, and other machinery requiring non-stop performance.

11. Cooling and ventilation

Standard cooling: Totally Enclosed Fan-Cooled (TEFC) (per IEC 60034-6, C411), which prevents dust, moisture, and debris from entering the motor (critical for humid/dusty environments like farms or mines). Auxiliary plastic fans boost airflow, maintaining stable temperatures in high-torque, high-heat conditions.

12. Winding

Constructed with 100% Copper Wire (not aluminum), which offers superior electrical conductivity, heat resistance, and durability. Copper windings extend motor life, reduce energy loss (lowering utility bills), and perform better than alternative materials in high-load, long-duration tasks.

13. Protection class

Standard IP54/IP55 Ingress Protection (dust-tight, water-resistant) safeguards against particles and low-pressure water jets—ideal for humid, dusty workspaces (e.g., food processing plants, construction sites, or outdoor equipment shelters). Higher IP ratings (e.g., IP65 for heavy rain/washdowns) are available on request.

14. Quality assurance

Every step—from design to final assembly—adheres to the ISO 9001 quality management system. This certification guarantees consistent manufacturing standards, reliable performance, and compliance with global industrial regulations, giving buyers confidence in product safety and longevity.

![3 phase motor 3 phase motor]()

How a 0.75 HP / 0.55 KW 3-Phase Motor Works

Principle of Electromagnetic Induction

The motor creates a rotating magnetic field when 3-phase supply flows through the stator. This field induces current in the rotor, which then starts rotating.

Role of Stator and Rotor

Both work together like a well-rehearsed dance—perfectly synchronized.

Starting Mechanisms

These motors often use:

The choice depends on load and installation requirements.

Top Applications

Industrial Machinery

Used in:

Conveyor systems

Mixers

Packaging machines

Their consistent torque helps maintain smooth operations.

Pumps and Compressors

It’s a reliable choice for:

Water pumps

Air compressors

Vacuum pumps

HVAC Systems

Ideal for:

Blowers

Fans

Ventilation units

Agricultural Uses

Farm equipment like:

Milking machines

Feed grinders

Small irrigation systems

![electric motor electric motor]()

Benefits of Using This Motor

High Efficiency and Low Energy Consumption

You get solid performance without skyrocketing electricity bills—perfect for continuous operations.

Durability and Long Life

Built with high-quality materials, these motors can withstand tough conditions.

Stable Power Delivery

3-phase motors avoid the flickering or surging issues often found in single-phase motors.

Installation Considerations

Wiring Requirements

Ensure proper 3-phase wiring with adequate earthing to prevent safety hazards.

Safety Precautions

Environmental Conditions

Check:

![What is a Variable Frequency Motor What is a Variable Frequency Motor]()

Maintenance Guidelines

Lubrication Practices

Bearings should be lubricated regularly to reduce friction and prevent wear.

Routine Inspections

Inspect:

Wiring

Bearings

Connections

Temperature rise

Motor Overload Protection

Use overload relays and thermal protectors to increase motor lifespan.

Factors to Consider Before Buying

Brand and Warranty

Choose reputable brands that offer:

Quality assurance

Long-term warranties

Application Requirements

Match speed, torque, and power rating to your exact application.

Budget and Energy Ratings

Look for IE2/IE3 motors to reduce long-term operating costs.

![Key Features of Aluminium Housing Induction Motors Key Features of Aluminium Housing Induction Motors]()

Common Problems and Solutions

Overheating

Cause: Overload or poor ventilation

Fix: Clean ventilation ducts, reduce load

Low Voltage Issues

Cause: Faulty supply

Fix: Check supply lines and connections

Excessive Noise

Cause: Worn bearings

Fix: Lubricate or replace bearings

Conclusion

A 0.75 HP / 0.55 kW 3-phase motor is a versatile, energy-efficient, and reliable solution for countless industrial, commercial, and agricultural applications. Its compact size, long lifespan, and stable performance make it an essential component for powering modern machinery. Whether you're upgrading your equipment or installing a new system, this motor offers dependable performance with excellent value.

FAQs

1. What is the voltage of a 0.75 HP 3-phase motor?

Typically 380V–415V, depending on region and manufacturer.

2. Is 0.75 HP enough for industrial use?

Yes, it’s widely used for light to medium industrial applications.

3. How many watts is a 0.75 HP motor?

Approximately 550 watts (0.55 kW).

4. How long can this motor run continuously?

With proper ventilation and load management, it can run for long hours without issues.

5. Can I use this motor for water pumps?

Absolutely—it’s a common choice for household and industrial pumps.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी