![AC Brake Motor 3 Phase AC Brake Motor 3 Phase]()

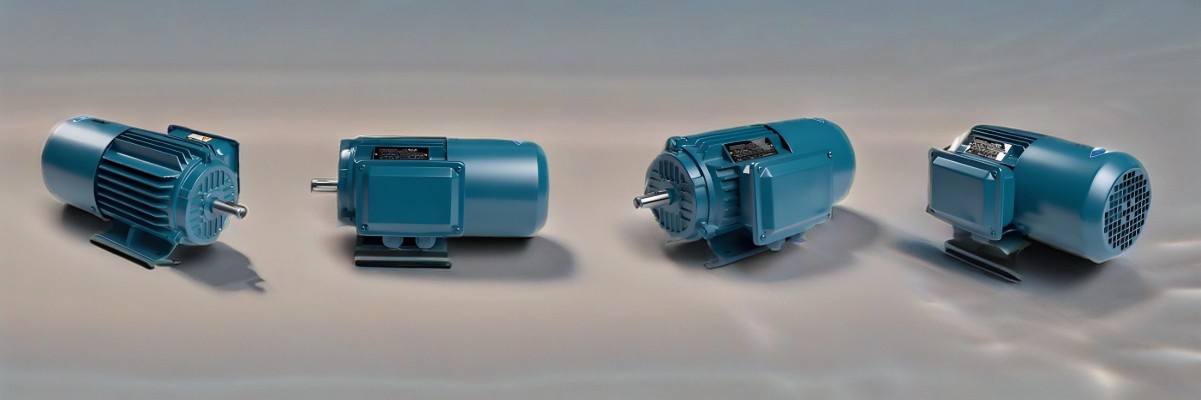

AC Brake Motor 3 Phase for Sale – Reliable & High-Performance Solutions

Looking for a high-quality 3-phase AC brake motor for sale? Whether you need precise stopping control, enhanced safety, or energy efficiency, an AC brake motor is a perfect solution. These motors are widely used in industrial, manufacturing, and automation applications, providing reliable braking and smooth operation.

What is an AC Brake Motor?

An AC Brake Motor (Three-Phase) is a specially designed motor that integrates an electromagnetic brake to provide instant stopping and holding torque, making it ideal for industrial applications requiring precise control, safety, and reliability. These motors are commonly used in conveyors, hoists, cranes, elevators, machine tools, and material handling systems.

How Does It Work?

· The motor runs normally when powered.

· When the power supply is cut, the brake system activates, bringing the motor to an immediate stop.

· The braking mechanism ensures safety, precision, and control in industrial applications.

![what is AC Brake Motor 3 Phase what is AC Brake Motor 3 Phase]()

Video of Yongzhuan AC Brake Motor 3 Phase

Key Features of 3-Phase AC Brake Motors

1. Fast and Reliable Braking

Designed to stop the motor quickly when power is disconnected, ensuring safety and precision.

2. High Efficiency & Performance

Most IE2, IE3, and IE4 efficiency-rated motors provide energy savings and smooth operation.

3. Durable and Long-Lasting

Built with premium materials, ensuring high durability and low maintenance costs.

4. Heavy-Duty Construction

Perfect for continuous operation in demanding industries like manufacturing, mining, and automation.

5. Electromagnetic or DC Brake Options

Different braking types offer customization for various applications.

![Key Features of 3-Phase AC Brake Motors Key Features of 3-Phase AC Brake Motors]()

Benefits of Using an AC Brake Motor

✅ Enhanced Safety

Stops machinery instantly in emergency situations, preventing accidents.

✅ Improved Productivity

Quick stopping and starting cycles increase operational efficiency.

✅ Precise Positioning

Essential for applications like hoists, conveyors, and cranes, requiring accurate positioning.

✅ Energy Efficiency

High-performance motors with low energy consumption, reducing electricity bills.

✅ Low Maintenance

Durable designs ensure long life with minimal servicing requirements.

![Benefits of Using an AC Brake Motor Benefits of Using an AC Brake Motor]()

Parameter Sheet: AC Brake Motor 3-Phase

A 3-phase AC brake motor is an essential investment for industries requiring precise stopping, safety, and efficiency. Whether you need one for conveyors, cranes, lifts, or automation, a high-quality brake motor can significantly improve operations.

1. General Specifications

| Parameter | Specification |

| Motor Type | Three-Phase AC Induction Motor with Brake |

| Brake Type | Electromagnetic Disc Brake / DC or AC Operated |

| Efficiency Class | IE2, IE3, IE4 (Energy Efficient Models Available) |

| Rated Power | 0.37 kW – 100 kW |

| Frequency | 50 Hz / 60 Hz |

| Rated Voltage | 220V / 380V / 400V / 415V / 690V / Customized |

| Rated Speed | 750 RPM – 3600 RPM (2, 4, 6, or 8 Pole Options) |

| Torque Control | Instant Braking with High Torque Hold |

| Cooling Method | IC411 (Self-Cooled), IC416 (Forced Ventilation), or Custom |

| Brake Release Method | Manual or Automatic (Spring-Applied, Electrically Released) |

| Mounting Type | Foot-Mounted, Flange-Mounted, Face-Mounted |

| Ambient Temperature | -20°C to +40°C (Custom Options Available) |

| Protection Class | IP55, IP56, IP65 (Dust & Water Resistant) |

| Certifications | CE, UL, CSA, IEC, ISO9001 |

2. Electrical Specifications

| Parameter | Specification |

| Rated Voltage | 220V / 380V / 415V / 690V (3-Phase) |

| Voltage Tolerance | ±10% |

| Frequency Range | 50 Hz / 60 Hz |

| Power Factor | 0.85 - 0.98 |

| Motor Current | Variable based on power rating |

| Starting Method | Star-Delta, DOL, or Soft Start |

| Winding Type | 100% Copper Windings for Maximum Efficiency |

| Overload Protection | Yes (Thermal Sensors Built-in) |

| Insulation Class | Class F / Class H (Enhanced Thermal Protection) |

3. Mechanical Specifications

| Parameter | Specification |

| Frame Size | 80 – 355 mm |

| Shaft Diameter | Up to 150 mm (Depending on Power Rating) |

| Shaft Material | High-Strength Steel / Stainless Steel (Optional) |

| Shaft Length | Customizable Based on Application |

| Bearing Type | Deep Groove Ball Bearings / Roller Bearings |

| Housing Material | Cast Iron / Aluminium (Lightweight Versions Available) |

| Weight | Varies Based on Power Rating (5 kg to 1000 kg) |

| Noise Level | ≤ 75 dB(A) |

| Vibration Level | Grade 1 (ISO 10816) |

4. Brake System Specifications

| Parameter | Specification |

| Brake Type | Electromagnetic Disc Brake / DC or AC Operated |

| Braking Torque | 5 Nm - 1000 Nm (Based on Motor Size) |

| Brake Response Time | Instantaneous (≤ 0.5 sec) |

| Brake Coil Voltage | DC 24V, 110V, 220V / AC 220V, 380V |

| Brake Release Type | Manual / Automatic Release |

| Lifespan | ≥ 2 Million Operations |

| Brake Material | Friction Lining with High Wear Resistance |

| Brake Duty Cycle | Continuous or Intermittent Duty |

5. Performance Characteristics

| Parameter | Specification |

| Torque Range | 1.5 - 5000 Nm |

| Starting Torque | 150% to 250% of Rated Torque |

| Breakdown Torque | 200% to 250% of Rated Torque |

| Efficiency | ≥ 85% (IE3, IE4 Models Available) |

| Braking Precision | ±1% of Rated Speed |

| Dynamic Braking | Available on Higher Power Ratings |

| Load Handling | Supports Variable Loads with Stable Speed |

6. Environmental & Protection Features

| Parameter | Specification |

| Ingress Protection (IP Rating) | IP55, IP56, IP65 (Dust & Water Resistant) |

| Cooling Type | IC411 (Self-Cooling) / IC416 (Forced Ventilation) |

| Corrosion Resistance | Available (Marine & Chemical-Resistant Coating Options) |

| Operating Temperature | -20°C to +40°C (Higher Temperatures on Request) |

7. Mounting Options

| Mounting Type | Specification |

| Foot-mounted (B3) | Standard Base Mounting with Fixed Bolts |

| Flange-mounted (B5) | Flange Attachment for Secure Installation |

| Face-mounted (B14) | Compact Installation with Face Mounting |

| Custom Mounting (B35/B34) | Available Upon Request |

Applications of 3-Phase AC Brake Motors

✦Material Handling & Conveyor Systems

Ensures safe and controlled movement of goods in warehouses and factories.

✦Cranes & Hoists

Provides instant braking for lifting applications, preventing load swings and drops.

✦Elevators & Lifts

Used in vertical transportation for smooth stopping and starting.

✦Packaging & Automation

Offers precision and accuracy in automated processes.

✦Metalworking & Machine Tools

Used in presses, saws, and lathes where quick stops are crucial.

![Applications of 3-Phase AC Brake Motors Applications of 3-Phase AC Brake Motors]()

How to Choose the Right 3-Phase AC Brake Motor

1. Select the Right Power Rating

Choose based on your application needs, typically ranging from 0.5HP to 100HP+.

2. Check the Brake Type

·Electromagnetic brakes – Ideal for automation and robotics.

·Spring-loaded brakes – Best for heavy-duty applications.

3. Ensure High Efficiency (IE3/IE4 Rated)

Higher efficiency means lower energy costs and improved performance.

4. Look for Reliable Construction

Motors should have high-quality bearings, insulation, and protection ratings (IP55, IP66, etc.).

5. Buy from a Trusted Supplier

Choose trusted brands like Yongzhuan, known for quality, reliability, and after-sales support.

![How to Choose the Right 3-Phase AC Brake Motor How to Choose the Right 3-Phase AC Brake Motor]()

Why Choose Yongzhuan AC Brake Motors?

At Yongzhuan, we offer premium-quality AC brake motors that ensure:

✅ Precision Braking – Instant stopping power

✅ Energy Efficiency – Compliant with IE3 and IE4 standards

✅ Durability – Built for heavy-duty applications

✅ Custom Solutions – Tailored for specific industrial needs

✅ Competitive Pricing – Best value for long-term performance

![Why Choose Yongzhuan AC Brake Motors Why Choose Yongzhuan AC Brake Motors]()

FAQs of AC Brake Motors 3 Phase

1. What is the main function of an AC brake motor?

It provides quick stopping when the power supply is cut, ensuring safety and control.

2. Can I use an AC brake motor for heavy-duty applications?

Yes! These motors are designed for industrial applications like hoists, cranes, and conveyors.

3. Are AC brake motors energy-efficient?

Yes, modern motors come with IE3/IE4 efficiency ratings, reducing energy consumption.

4. What industries use 3-phase AC brake motors?

Industries like manufacturing, material handling, mining, and automation rely on brake motors for precision.

5. Where can I buy a high-quality AC brake motor?

You can purchase premium AC brake motors from Yongzhuan, ensuring performance and reliability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी