The Workhorse of Industry: Understanding Induction Motors

Have you ever wondered what makes so much of our modern world spin? From the conveyors in bustling factories to the pumps supplying water to our homes, a hidden hero is constantly at work: the induction motor. These incredible machines are arguably the most common type of electric motor used in industrial applications, and for very good reason! They are the unsung workhorses, powering countless processes silently and efficiently.

If you peer into almost any industrial facility, you're bound to find a multitude of induction motors humming away, diligently converting electrical energy into mechanical motion. It’s quite amazing, isn't it, how something so fundamental underpins so much of our daily lives and economic activity?

![What is a Three-Phase Motor What is a Three-Phase Motor]()

What Are Induction Motors?

So, what exactly is an induction motor? Picture a motor that runs on alternating current (AC) and uses electromagnetic induction to create motion. It’s got a stator, which generates a rotating magnetic field, and a rotor that spins to produce mechanical energy. No brushes, no fuss—just a simple, robust design that’s been around since the 19th century. Whether it’s a single-phase motor for your home’s air conditioner or a three-phase beast in a factory, induction motors get the job done.

An induction motor, often referred to as an asynchronous motor, operates by inducing an electric current in the rotor via electromagnetic induction from the stator. These motors are known for their ruggedness, simplicity, and efficiency, making them the preferred choice for high-load applications and continuous duty operations.

There are two main types:

They are widely used in everything from compressors and pumps to fans and conveyors.

Induction Motor Market Trends for 2025

The U.S. induction motor market is on a roll! Valued at around $27.85 billion in 2023, it’s projected to soar to $65.33 billion by 2033, with a compound annual growth rate (CAGR) of 8.9%. What’s driving this? The boom in electric vehicles, smart manufacturing, and stricter energy efficiency regulations are pushing demand sky-high.

Three-phase induction motors, in particular, are gaining traction for their use in EV traction systems and heavy-duty industrial applications. It’s like the industry’s riding a wave of innovation, and these manufacturers are surfing it.

![Induction motors Induction motors]()

How We Chose the Top Induction Motor Manufacturers

Picking the top 10 wasn’t just about who’s the biggest. We looked at innovation (are they breaking new ground?), product quality (do their motors last?), market presence (are they trusted?), and sustainability (are they green?). We also considered their U.S. operations, customer support, and ability to meet diverse industry needs. These companies aren’t just making motors—they’re shaping the future of industry.

Top 10 Induction Motor Manufacturers in the U.S. for 2025

Let’s meet the rockstars of the induction motor world. These 10 U.S. manufacturers are setting the standard for 2025.

#1. Baldor Electric Company (ABB) – The Benchmark of Reliability

· Unmatched Performance Across Industries

Baldor Electric, now a part of ABB Group, is a recognized leader in manufacturing premium-efficiency induction motors for industrial applications. Their Super-E® motors surpass NEMA Premium standards, offering unmatched durability and efficiency.

· ABB’s Focus on Energy Efficiency

In 2025, ABB continues to integrate smart features like condition monitoring and predictive maintenance. The motors are widely used in food & beverage, mining, and logistics sectors.

Key Product: Baldor-Reliance® RPM XE and Super-E® NEMA motors

Website: https://new.abb.com/motors-generators

![abb abb]()

#2. Siemens USA – Smart, Powerful, and Connected

· SIMOTICS: The Gold Standard

Siemens is a global automation powerhouse, and its U.S. branch remains dominant in the induction motor sector. The SIMOTICS GP and SD lines offer versatile solutions for applications in manufacturing, water treatment, and power generation.

· Integration with Industrial IoT

All Siemens induction motors now support MindSphere for cloud-based analytics, offering real-time performance diagnostics and reduced downtime.

Key Product: SIMOTICS SD200 Severe Duty Motors

Website: https://new.siemens.com/us

![siemens siemens]()

#3. Yongzhuan Motor – Leading Manufacturer From China

· Background and Product Offerings

Yongzhuan-Motor Co., LTD is a comprehensive motor design and manufacturing enterprise with 25-years experience, which covers an area of 10,000 square meters and annual production of 3000,000 motors. Their main products are YE3(IE3), YE4(IE4) high-efficiency three-phase induction motor, YBX3 explosion-proof three-phase induction motor, gear motor, gear reducer, gearbox, and other special customized motors.

· Key Industry Uses and Trusted Reputation

Their motors are extensively used in many industries, like mining and metalworking, due to their rugged design. The products have passed CE, authoritative third party quality testing and other certifications. Their products are mainly exported to the United States, Germany, Japan, Italy and other dozens of countries and regions.

· Most Cost-effective and High Customization capability

Yongzhuan-Motor stands out for offering some of the most cost-effective induction motor solutions in the European market. Their ability to provide high-quality motors at competitive prices makes them an attractive choice for businesses looking to optimize their operational costs. Additionally, Yongzhuan-Motor excels in customization, offering tailored solutions to meet specific industry needs and unique application requirements.

Key Product: IEC Standard IE2 IE3 IE4 Induction Motor, Special 3-phase motor(Brake Motor, Explosion-proof Motor, VFD Motor), Helical Gear Motor, Cycloidal Gear Motor, Specialized Induction Motor for Gearboxes

Website: https://www.victory-motor.com/

![yongzhuan&victory motor yongzhuan&victory motor]()

#4. GE Industrial Motors – Heavy-Duty Excellence

· Medium and Large Frame Induction Motors

GE Industrial Motors, under GE Vernova, is known for manufacturing large-scale induction motors for industries like steel, paper, and mining. These motors are designed for continuous operation in harsh environments.

· Custom Solutions and Long-Term Durability

GE's custom motor designs meet IEEE and API standards, and they now include remote monitoring features for preventive maintenance.

Key Product: MV3000 Series and Custom Engineered Medium Voltage Motors

Website: https://www.gevernova.com

![GE GE]()

#5. WEG Electric Corp – Globally Recognized, Locally Trusted

· W22 Line and Industrial Applications

Though headquartered in Brazil, WEG Electric has a major U.S. presence. Their W22 induction motors are widely adopted in oil & gas, pulp & paper, and HVAC systems.

· Compliance with NEMA Premium Standards

The W22 line meets IE3/IE4 efficiency levels, making it one of the most eco-friendly and reliable options in 2025.

Key Product: W22 NEMA Premium Efficiency Motor

Website: https://www.weg.net

![weg weg]()

#6. Toshiba International Corporation – Built for Extreme Duty

· EQP Global Series

Toshiba’s induction motors are known for operating in the most demanding conditions—from wastewater plants to refineries. Their EQP Global SD and Vector series offer rugged performance with corrosion-resistant housing.

· Strong Presence in Water and HVAC Systems

Toshiba motors are commonly chosen for municipal water utilities, HVAC, and data centers, where continuous operation is critical.

Key Product: EQP Global Severe Duty Motor

Website: https://www.toshiba.com/tic

![toshiba toshiba]()

#7. Nidec Motor Corporation – Innovative Induction Engineering

· SynRA and General Purpose Induction Motors

Nidec’s U.S. operations have grown with a focus on energy-efficient induction motors. Their U.S. Motors brand is known for HVAC and industrial applications.

· Focus on Electrification Trends

Nidec is heavily invested in the EV and automation space, developing induction motors that support clean energy transitions.

Key Product: RESCUE® and SynRA Series Motors

Website: https://acim.nidec.com

![nidec nidec]()

#8. TECO-Westinghouse – Power and Performance

· MAX-PEV and High HP Motors

TECO-Westinghouse designs and manufactures high-power induction motors up to 100,000 HP. Their motors serve power plants, chemical plants, and other heavy-duty sectors.

· Trusted in Oil & Gas, Marine, and Manufacturing

Their motors are designed for severe duty, often used where maximum uptime is essential.

Key Product: MAX-PEV Medium Voltage Induction Motor

Website: https://www.tecowestinghouse.com

![teco teco]()

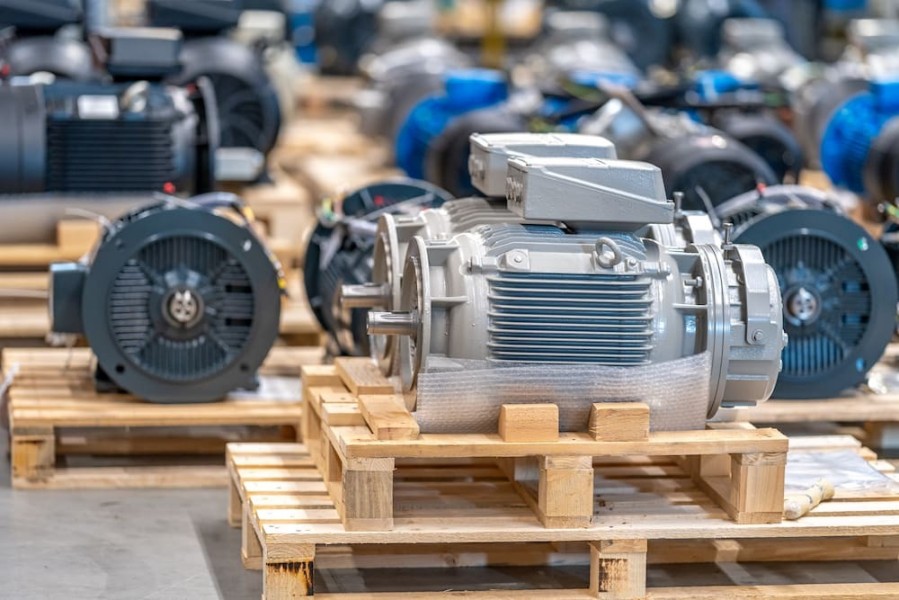

#9. Franklin Electric – Induction Motors for Water Systems

· Submersible and Vertical Induction Motors

Franklin Electric specializes in motors for groundwater, wastewater, and agriculture. Their induction motors are designed for submersible pumps and vertical turbines, built to operate in extreme wet conditions.

· Focus on Rural and Municipal Utilities

Their water system motors are widely used in municipal water supplies and irrigation systems.

Key Product: 6-Inch Sand Fighter Submersible Motors

Website: https://www.franklin-electric.com

![Franklin Electric Franklin Electric]()

#10. U.S. Motors (Nidec) – Backbone of Building Systems

· HVAC-R Specific Designs

U.S. Motors, a division of Nidec, is well-known in the HVAC-R industry. Their RESCUE EcoTech® series has been a game-changer for energy efficiency in commercial and residential buildings.

· Dependability and Efficiency in One Package

Their motors are quiet, compact, and designed for 24/7 operation, making them ideal for rooftop units, chillers, and air handlers.

Key Product: RESCUE EcoTech® and Inverter Duty Motors

Website: https://acim.nidec.com/usmotors

![U.S. Motors (Nidec) U.S. Motors (Nidec)]()

Challenges

Even the best manufacturers face roadblocks. In 2025, the industry’s dealing with some serious challenges that could shake things up.

Material Shortages

Building an induction motor isn’t cheap, especially when materials like copper and rare earth elements are in short supply. Geopolitical tensions and supply chain disruptions are driving up costs, forcing manufacturers to get creative with recycling or alternative designs like switched reluctance motors. It’s like trying to cook a gourmet meal when the pantry’s half-empty.

Global Competition

U.S. manufacturers are in a global cage match with giants from China and Europe. The Asia-Pacific region, led by China, is expected to claim over 40% of the global market by 2025. Companies like Siemens, ABB, and China’s Dongchun are fierce competitors, pushing U.S. firms to innovate faster. It’s a race where standing still isn’t an option.

![Introduction Introduction]()

What's Next? The Future of Induction Motors in the U.S.

The journey for induction motors in the U.S. market is far from over; in fact, it's entering a new and exciting phase. As industries continue to evolve, so too will the demands placed on these essential machines, leading to even more sophisticated developments.

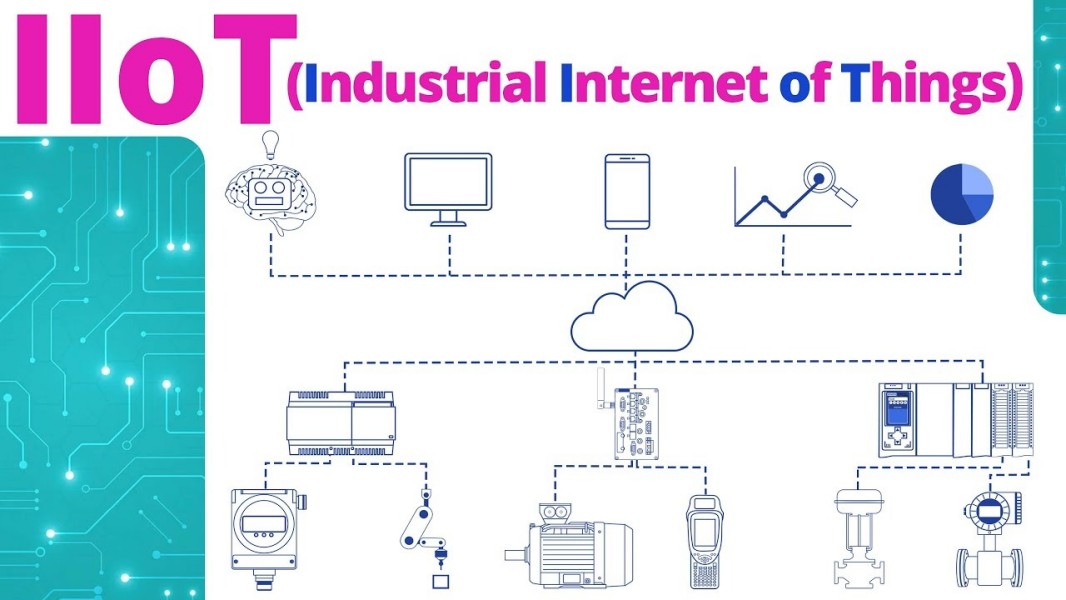

The Smart Motor Revolution: IoT and Predictive Maintenance

Imagine a motor that can tell you it's about to fail before it actually does. That's the promise of the "smart motor" revolution, driven by the Internet of Things (IoT) and artificial intelligence (AI). Future induction motors will increasingly come equipped with integrated sensors that continuously monitor parameters like temperature, vibration, current, and voltage. This data will be analyzed by AI algorithms to provide real-time performance insights, identify potential issues, and enable predictive maintenance. This shift from reactive to proactive maintenance will drastically reduce downtime, optimize operational efficiency, and extend the lifespan of industrial assets.

Pushing the Boundaries of Efficiency (IE5 and Beyond)

While IE3 and IE4 efficiency standards are currently prevalent, the pursuit of even greater energy savings will continue. Expect to see manufacturers pushing towards IE5 "Ultra-Premium Efficiency" induction motors becoming more common. This will involve further innovations in rotor design, stator windings, and material science to minimize every conceivable energy loss. The drive for sustainability and reduced carbon footprints will ensure that efficiency remains a primary battleground for innovation.

Sustainable Manufacturing and Lifecycle Management

Beyond just the operational efficiency of the motors, manufacturers will increasingly focus on the sustainability of their production processes and the entire lifecycle of their products. This means exploring more environmentally friendly materials, reducing waste in manufacturing, and implementing robust recycling and end-of-life management programs for motors. Companies will aim for not just energy-efficient products but also carbon-neutral manufacturing processes, contributing to a truly circular economy.

![IIoT Integration IIoT Integration]()

Frequently Asked Questions (FAQs)

1. Are induction motors energy efficient?

Answer: Yes, especially modern designs. Most major manufacturers now produce motors that meet or exceed NEMA Premium and IE3/IE4 standards.

2. What industries use induction motors the most?

Answer: Manufacturing, HVAC, water utilities, oil & gas, agriculture, and transportation all rely heavily on induction motors.

3. Can I get custom induction motors?

Answer: Absolutely. Yongzhuan Motor, TECO-Westinghouse, and WEG provide custom-engineered solutions for unique industry needs.

4. What’s the difference between induction and synchronous motors?

Answer: Induction motors use electromagnetic induction to operate asynchronously, while synchronous motors run at constant speed with rotor-stator synchronization.

5. Where can I get cost-effective IEC-compliant IE3/IE4 motors that can be customized in small quantities?

Answer: As a leading manufacturer of induction motors from China, Yongzhuan Motor can provide efficiency motors that comply with IEC standards and support customization, which ranges from case size, power, frequency, voltage, poles, temperature, material to additional features of the motor. For speed requirements, a wide range of gearbox customer solutions are also available. With high quality raw materials and an excellent supply system in China, the price of induction motors is not too high. Yongzhuan Motor aims to provide customers with motor solutions to help them increase their sales margins!

![What is a Variable Frequency Motor What is a Variable Frequency Motor]()

Conclusion: Choosing the Best Induction Motor Manufacturer

As the demand for energy-efficient, durable, and smart motors grows in 2025, these top 10 U.S.-based manufacturers remain the go-to names in the industry. Whether you need a motor for a large-scale refinery or a rooftop HVAC system, choosing the right manufacturer ensures better performance, lower costs, and minimal downtime.

Take the time to evaluate your operational needs and consider factors like smart technology integration, energy efficiency ratings, and aftermarket support.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी