Introduction

Ever wondered why a perfectly good three-phase motor suddenly gives up the ghost? If you’ve worked in an industrial setup or managed heavy machinery, you’ve probably seen it happen: the motor starts smoking, stops spinning, or just plain burns out. It’s frustrating, costly, and can bring operations to a screeching halt. Three-phase motors are the workhorses of factories, HVAC systems, and countless other applications, but they’re not invincible.

In this article, we’ll dive into why these motors burn out, how to spot the warning signs, and what you can do to keep them humming along for years. Ready to get to the bottom of this? Let’s roll!

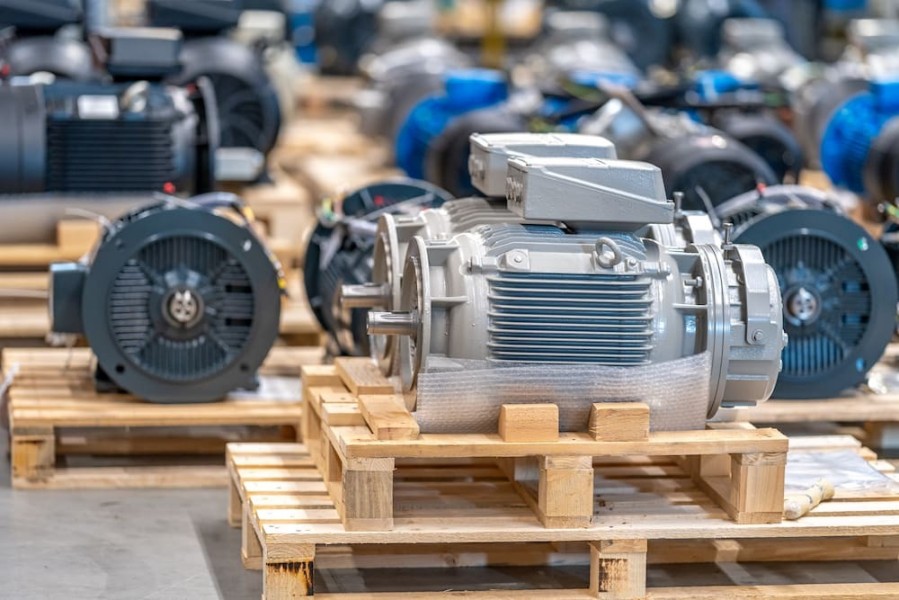

![Introduction Introduction]()

What is a Three-Phase Motor?

Before we get into the nitty-gritty of burnout, let’s talk about what a three-phase motor actually is. Picture a three-phase motor as the heart of heavy-duty machinery. It’s an electric motor powered by three alternating currents, which makes it super efficient and capable of handling big tasks. These motors are everywhere—think conveyor belts, pumps, compressors, and even the fans keeping your office cool. They’re designed to be robust, but like any piece of equipment, they have their limits.

How Does It Work?

So, how does this powerhouse operate? A three-phase motor runs on three electrical phases that are out of sync with each other, creating a rotating magnetic field. This field pulls the motor’s rotor along, making it spin and do its job. It’s like a perfectly choreographed dance where each phase takes its turn to keep the rhythm going. But if one dancer stumbles—say, a phase drops or the load gets too heavy—the whole performance can collapse, leading to burnout.

![What is a Three-Phase Motor What is a Three-Phase Motor]()

Top Reasons Why a Three-Phase Motor Burns Out

Motors don’t just burn out for no reason. There’s always a culprit, and usually, it’s one of a handful of usual suspects. Let’s break down the most common reasons these motors call it quits.

1. Overheating

Overheating is one of the most common causes of motor failure.

Why it happens:

· Running the motor beyond its rated capacity

· Poor ventilation or blocked airflow

· High ambient temperature

· Excessive duty cycles without rest

Solution:

Keep the motor clean, ensure good ventilation, and never exceed its rated load.

2. Phase Loss (Single Phasing)

When one of the three supply phases is lost, the motor draws more current through the remaining phases. This causes uneven load distribution and overheating, eventually leading to burnout.

Solution:

Install phase failure relays to detect and protect the motor from running under these conditions.

3. Voltage Imbalance

A voltage imbalance as small as 1-2% can cause the motor to draw excessive current, leading to increased heat and insulation breakdown.

Solution:

Regularly monitor the voltage and ensure a balanced power supply from all phases.

![Voltage Imbalance Voltage Imbalance]()

4. Improper Motor Protection

If your motor isn’t equipped with the right overload relays or thermal protection, it can run beyond safe limits, burning out over time.

Solution:

Use thermal overload protectors, fuses, and circuit breakers to shut the motor down under unsafe conditions.

5. Poor Maintenance Practices

Dust, dirt, and debris can clog cooling vents, damage insulation, or affect bearings.

Solution:

Schedule routine maintenance checks. Clean the motor housing, inspect for loose connections, and grease bearings as needed.

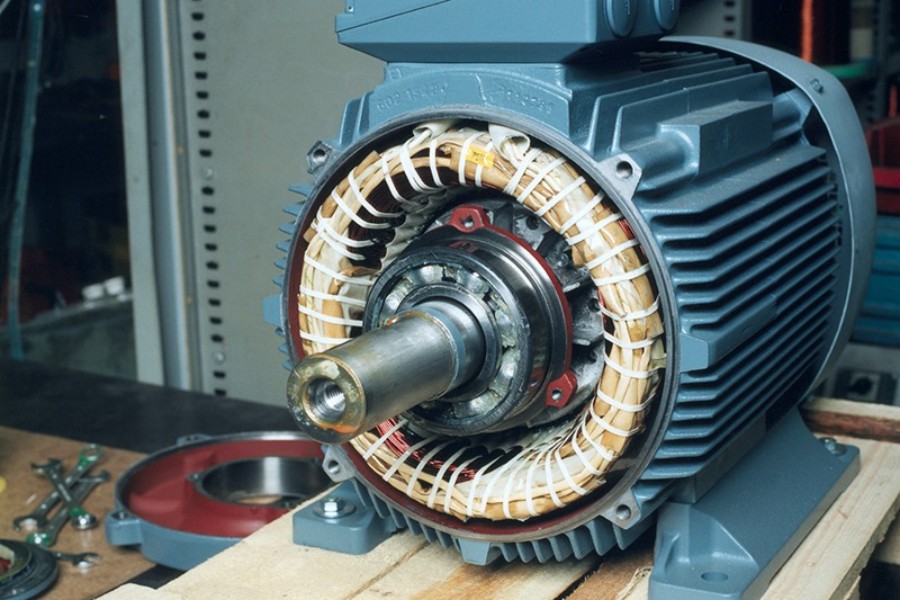

6. Bearing Failures

Worn or improperly lubricated bearings cause mechanical stress, which leads to misalignment, overheating, and eventually motor burnout.

Solution:

Use high-quality bearings and lubricate them periodically as per manufacturer recommendations.

![Bearing Failures Bearing Failures]()

7. Overloading the Motor

Running a motor under continuous overload can cause the winding insulation to fail, resulting in short circuits and burnout.

Solution:

Always match the motor’s power rating to the application load. If more power is needed, consider upsizing the motor.

8. Frequent Start-Stop Cycles

Each start draws a high inrush current. Too many starts in a short time causes excessive heating, degrading the motor windings.

Solution:

Limit frequent cycling or use soft starters and VFDs (Variable Frequency Drives) to minimize the impact.

9. Harmonic Distortion

Non-linear loads, especially from VFDs or inverters, can create harmonics in the power supply, affecting motor performance and life.

Solution:

Use harmonic filters or ensure the VFD is compatible and properly tuned for motor use.

![Harmonic Distortion Harmonic Distortion]()

10. Moisture and Environmental Contamination

Water, dust, or chemicals can damage motor insulation, leading to short circuits and electrical faults.

Solution:

Use sealed motors (IP-rated) in harsh environments and install protective covers or enclosures.

How to Prevent Three-Phase Motor Burnout: Best Practices

The good news? Motor burnout is highly preventable—if you follow the right practices. Here’s a complete, actionable guide on how to prevent three-phase motor burnout and keep your operations running smoothly.

1. Install Proper Overload Protection

Your first line of defense against motor burnout is a well-calibrated overload protection system.

Best Practices:

· Use thermal overload relays tailored to the motor’s rated current.

· Set protection devices to trigger at 110–115% of full load amps.

· Choose protection systems with manual and automatic reset options for safe recovery.

✅ Benefits:

2. Monitor and Maintain Voltage Balance

Unbalanced voltages across the three phases can increase motor temperature dramatically.

Best Practices:

· Use a voltage monitor relay to detect and disconnect during unbalanced supply.

· Keep the voltage imbalance below 1%.

· Regularly check connections for corrosion, looseness, or damaged insulation.

✅ Benefits:

3. Ensure Proper Motor Sizing for the Load

Running a small motor on a heavy load is a recipe for burnout.

Best Practices:

· Always perform a load calculation before selecting a motor.

· Allow a 10–15% power margin over the actual load.

· Consider peak load demands and startup torque when sizing.

✅ Benefits:

![Ensure Proper Motor Sizing for the Load Ensure Proper Motor Sizing for the Load]()

4. Improve Cooling and Ventilation

Inadequate ventilation or blocked air pathways can lead to internal overheating.

Best Practices:

· Keep motor cooling fans and vents free of dust and debris.

· Avoid placing the motor in confined or poorly ventilated spaces.

· Consider forced ventilation (IC416 cooling) for high-temperature zones.

✅ Benefits:

5. Conduct Routine Maintenance Checks

A solid maintenance plan can spot early signs of wear or failure.

Best Practices:

· Perform monthly inspections for bearing noise, vibrations, or leaks.

· Check for loose terminals, discoloration, or insulation wear.

· Use infrared thermal scanning to detect overheating areas.

✅ Benefits:

6. Protect Against Environmental Factors

Exposure to moisture, dust, and chemicals can corrode and damage internal components.

Best Practices:

· Use motors with IP55 or IP65 enclosures for dusty or wet environments.

· Install motor covers or shelters in outdoor applications.

· Use space heaters or drain plugs to prevent condensation inside the motor.

✅ Benefits:

![Protect Against Environmental Factors Protect Against Environmental Factors]()

7. Install Phase Failure and Undervoltage Protection

Single phasing is a silent motor killer that occurs when one phase drops out.

Best Practices:

· Use phase failure relays that shut down the motor during fault conditions.

· Add undervoltage relays to detect dips that can stress motor windings.

· Monitor power quality, especially in regions with unstable supply.

✅ Benefits:

8. Use the Right Starting Method

Incorrect or harsh starts can lead to high inrush currents and strain the motor.

Best Practices:

· Use star-delta starters, soft starters, or VFDs (Variable Frequency Drives) for large motors.

· Avoid frequent on/off cycling, which increases thermal stress.

· Monitor start-up duration and torque behavior.

✅ Benefits:

9. Lubricate Bearings Regularly

Bearing failure is one of the top causes of motor burnout due to increased friction.

Best Practices:

· Lubricate based on the manufacturer’s guidelines.

· Avoid over-lubricating, which can cause seal damage or leakage.

· Use high-quality grease suitable for your operating environment.

✅ Benefits:

![Lubricate Bearings Regularly Lubricate Bearings Regularly]()

10. Keep Records and Track Performance

Keeping tabs on motor performance helps predict failures before they happen.

Best Practices:

· Maintain logs of voltage, current, and temperature trends.

· Use condition monitoring tools like vibration sensors or motor analyzers.

· Schedule predictive maintenance instead of reactive repairs.

✅ Benefits:

Quick Preventive Maintenance Checklist

| Task | Frequency |

| Check for loose electrical connections | Monthly |

| Clean motor vents and fans | Monthly |

| Inspect insulation resistance | Quarterly |

| Lubricate motor bearings | As per OEM guidelines |

| Test protection devices | Semi-annually |

| Conduct thermal imaging | Annually |

What to Do If Your Motor Burns Out

Despite your best efforts, burnout can still happen. Here’s what to do when the worst-case scenario hits.

Diagnosing the Failure

Don’t just swap out the motor and call it a day. Get a professional to diagnose the root cause—whether it’s overloading, single-phasing, or something else. This step is crucial to prevent the new motor from meeting the same fate. Think of it as figuring out why your car broke down before buying a new one.

Repair vs. Replacement

Should you fix the old motor or buy a new one? It depends. If the damage is minor and the motor is relatively new, rewinding or repairing might make sense. But if it’s old or severely damaged, replacement is often the smarter choice. Compare repair costs to the price of a new, energy-efficient model. Sometimes, a fresh start is the best way to go.

![What to Do If Your Motor Burns Out What to Do If Your Motor Burns Out]()

Conclusion

Three-phase motor burnout is a pain, but it’s not inevitable. By understanding the causes—overloading, voltage issues, single-phasing, insulation failure, and environmental factors—you can take steps to protect your motor. Regular maintenance, proper load management, and a little vigilance go a long way. And if burnout does strike, don’t panic; diagnose the issue and decide whether to repair or replace. Your motor is the heart of your operation, so treat it with care, and it’ll keep your business spinning smoothly. Got a motor request? Let me know in the right column—I’d love to connect you!

FAQs

1. Can a motor burn out if it runs too long?

Yes. Continuous overuse without rest or proper cooling can cause the motor to overheat and burn out.

2. What happens during phase loss?

The motor continues running on two phases, causing unbalanced current, overheating, and eventually burnout.

3. How can I tell if a motor is overheating?

Signs include a burning smell, discoloration, or the motor becoming too hot to touch.

4. How often should I maintain a three-phase motor?

Ideally, perform maintenance every 3 to 6 months, depending on usage and environment.

5. What is the lifespan of a well-maintained three-phase motor?

With proper care, a motor can last 10 years or more.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी