Introduction

Ever stood in front of a motor spec sheet, scratching your head over whether to go single-phase or three-phase? It’s like choosing between a bike and a truck—both get you somewhere, but the right choice depends on the journey. In 2025, with industries and homes relying on electric motors for everything from fans to factory lines, picking the right motor can save you money, boost performance, and keep things running smoothly.

So, what’s the deal with single-phase and three-phase motors, and how do you know which one’s your match? In this ultimate guide, I’ll break down their differences, benefits, challenges, and how to choose the perfect fit for your needs. Ready to power up your knowledge? Let’s dive in!

![single & 3 phase motor single & 3 phase motor]()

What Are Single-Phase and Three-Phase Motors?

Single-phase and three-phase motors are like siblings with different personalities. Both are AC induction motors, using a magnetic field to spin a rotor and produce mechanical power. The difference lies in their power supply: single-phase motors run on one alternating current, while three-phase motors use three, offset to create a smoother, more powerful rotation. Think of single-phase as a solo guitarist strumming a tune and three-phase as a full band playing in perfect sync.

How Single-Phase Motors Work

Single-phase motors are the simpler of the two. They use one AC power phase, typically found in homes at 120V or 230V. A capacitor or auxiliary winding creates a second phase to start the motor, like giving it a nudge to get moving. Once running, the stator’s magnetic field keeps the rotor spinning. They’re great for smaller tasks but can struggle with heavy loads, like a bicycle trying to haul a trailer.

Key Features:

Used in:

· Ceiling fans

· Water pumps

· Air conditioners

· Refrigerators

![ie2 single phase motor ie2 single phase motor]()

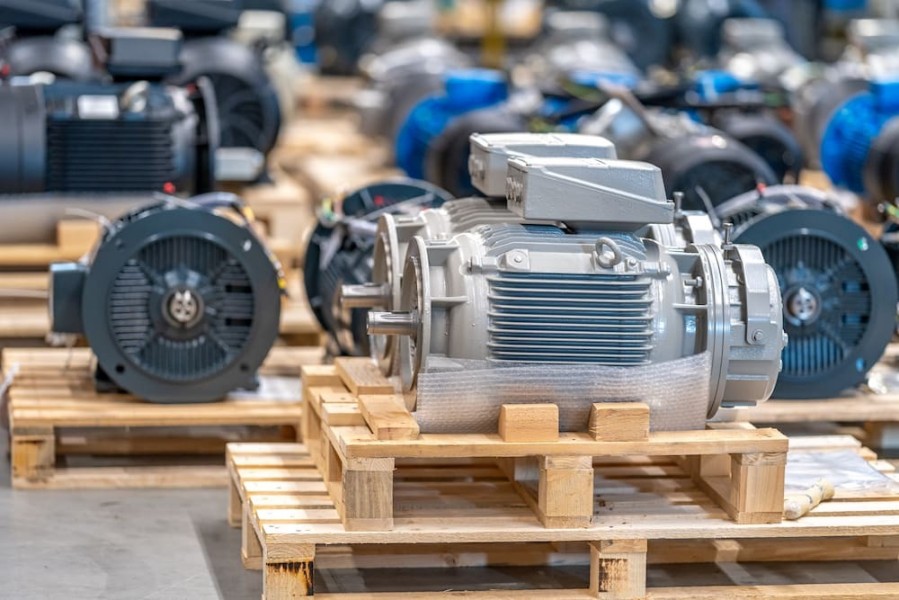

How Three-Phase Motors Work

Three-phase motors are the heavy lifters. They use three AC currents, each offset by 120 degrees, to create a rotating magnetic field that’s steady and powerful. No capacitor needed—these motors start and run smoothly on their own, delivering consistent torque. It’s like a well-oiled machine, perfect for industrial tasks where power and reliability are non-negotiable.

Key Features:

Used in:

· Industrial machinery

· Elevators

· Conveyors

· Large HVAC systems

![ie3 and ie4 motor ie3 and ie4 motor]()

Key Differences Between Single-Phase and Three-Phase Motors

So, what sets these motors apart? It’s all about power, efficiency, and application. Let’s break it down.

Power Supply Requirements

Single-phase motors plug into standard household power (120V or 230V), making them easy to use where three-phase power isn’t available. Three-phase motors need a three-phase supply (typically 208V, 400V, or 480V), common in industrial settings. It’s like choosing between a regular outlet for your phone charger and a heavy-duty one for a factory machine.

Efficiency and Performance

Three-phase motors are the efficiency champs, often hitting 90-96% efficiency (IE3/IE4 standards), compared to single-phase motors at 70-85%. Three-phase motors deliver smoother torque and higher power, making them ideal for heavy loads. Single-phase motors, while simpler, can be less efficient and struggle with high-torque starts. Think of three-phase as a V8 engine and single-phase as a four-cylinder—both work, but one’s built for speed.

Technical Differences Between Single and Three-Phase Motors

| Feature | Single-Phase Motor | Three-Phase Motor |

| Voltage Requirement | 220V | 380V - 480V |

| Starting Method | Capacitor start | Self-starting |

| Power Range | Up to 5 HP | 1 HP and above (up to 1000+ HP) |

| Torque Output | Low | High |

| Efficiency | Moderate | High |

| Maintenance | Simple | Moderate |

![single phase motor single phase motor]()

Advantages of Single-Phase Motors

Single-phase motors have their own charm. Let’s explore why they’re a go-to for many.

Cost and Availability

Single-phase motors are like the budget-friendly option at the motor store. They’re cheaper to buy and install, often costing 20-30% less than three-phase models. Plus, they’re widely available since most homes and small businesses have single-phase power. It’s like picking a reliable, affordable car that’s easy to find parts for.

Simplicity and Ease of Use

These motors are straightforward, with fewer components and simpler wiring. They’re plug-and-play for small setups, like a home workshop or a retail store. No need for complex electrical upgrades—just plug them into a standard outlet, and you’re good to go. It’s like using a basic smartphone that does the job without extra bells and whistles.

![double-value capacity single phase motor double-value capacity single phase motor]()

Advantages of Three-Phase Motors

Three-phase motors are the powerhouses of industry. Here’s why they shine.

High Efficiency and Power

Three-phase motors are like the marathon runners of motors—efficient and strong. Their three-phase power delivery means smoother operation, higher torque, and less energy waste. With efficiency ratings up to 96% (IE4), they save big on energy costs, especially for 24/7 operations. It’s like choosing a hybrid SUV that’s powerful yet fuel-efficient.

Role of Variable Frequency Drives (VFDs)

VFDs are like the brains behind three-phase motors. They adjust speed and power based on demand, cutting energy use by up to 30%. This makes three-phase motors even more efficient for applications like conveyors or pumps with varying loads. It’s like adding cruise control to your car for better mileage.

![What is a Three-Phase Motor What is a Three-Phase Motor]()

✅ When to Choose a Single-Phase Motor

Single-phase motors are the go-to for smaller, everyday tasks. Let’s see where they fit.

Residential and Small-Scale Uses

You’ll find single-phase motors in household appliances like washing machines, air conditioners, and ceiling fans. They’re also common in small businesses, powering tools in workshops or pumps in farms. With power ratings from 0.1 kW to 3 kW, they’re perfect for light-duty jobs, like a trusty bicycle for short trips.

· You’re powering a household appliance.

· You're in a location where only single-phase power is available.

· You’re running small-scale equipment like fans or pumps.

· Your startup budget is limited.

Simple and inexpensive, this is the go-to for residential users and light commercial operations.

![single phase electric motor single phase electric motor]()

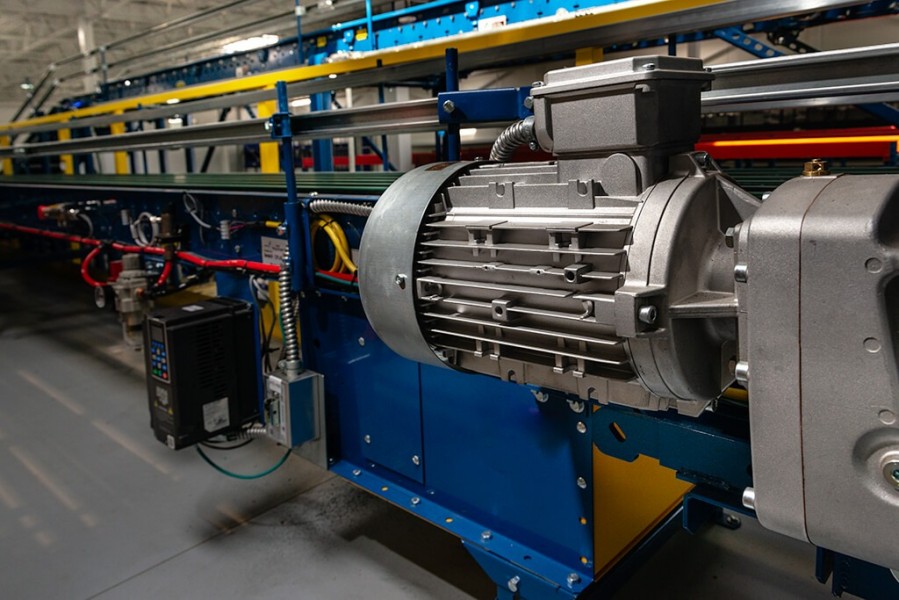

✅ When to Choose a Three-Phase Motor

Three-phase motors are the muscle behind big operations. Here’s where they dominate.

Industrial and Heavy-Duty Uses

From factory conveyor belts to heavy pumps in mining, three-phase motors are the backbone of industry. With power ratings from 0.75 kW to 500 kW, they handle massive loads in manufacturing, logistics, and energy sectors. They’re like the heavy-duty trucks hauling goods across the industrial landscape.

· You're powering heavy machinery or running continuous operations.

· You want the best possible efficiency over time.

· Your facility is equipped with three-phase power.

· You care about smoother operation and longevity.

Three-phase motors are the industrial workhorses.

![Conclusion Conclusion]()

Challenges of Choosing Between Single-Phase and Three-Phase Motors

Picking the right motor isn’t always a walk in the park. Let’s dive into the hurdles.

Infrastructure Limitations

Single-phase power is everywhere in homes, but three-phase power is mostly in industrial zones. If your facility only has single-phase power, installing a three-phase motor means costly electrical upgrades. It’s like needing a new road to drive a bigger truck—possible, but not always practical.

Cost Considerations

Single-phase motors are cheaper upfront, but three-phase motors save more in the long run due to higher efficiency. However, their higher initial cost (20-30% more) and infrastructure needs can strain budgets. It’s like choosing between a cheap phone with high data costs and a pricier one that saves on bills.

How to Choose the Right Motor for Your Needs

Picking the right motor is like choosing the perfect tool for a job. Here’s how to nail it.

Assessing Power Needs

Start with your application’s demands. Light tasks like running a fan need a single-phase motor (0.1-3 kW). Heavy loads, like industrial conveyors, call for three-phase motors (1-500 kW). Calculate your load’s horsepower and duty cycle to avoid under- or over-sizing, like picking the right shoe size for a run.

Evaluating Infrastructure Availability

Check your power supply. Homes and small shops usually have single-phase power, making single-phase motors the easy choice. Factories with three-phase power can leverage the efficiency of three-phase motors. Confirm with your electrician—it’s like checking if your kitchen can handle a new appliance.

How to Make the Right Choice

Before buying a motor, ask yourself:

· What’s the power supply available at my location?

· How much torque do I need?

· Is efficiency or cost more important in the short vs long term?

· How often and how long will the motor run?

When in doubt, consult with a professional supplier.

![3 & single phase motor 3 & single phase motor]()

Maintenance Tips for Single- and Three-Phase Motors

Want your motor to last? A little TLC goes a long way. Here’s how to keep it humming.

Routine Inspections and Cleaning

Treat your motor like a car needing regular checkups. Every few months, check for strange noises, vibrations, or overheating. Clean dust from vents to ensure proper cooling, especially for single-phase motors in dusty workshops. It’s like clearing leaves from a gutter to prevent clogs.

Lubrication and Cooling Strategies

Motors need grease and airflow to stay happy. Lubricate bearings regularly to reduce friction, especially for three-phase motors under heavy loads. Keep cooling fins clear to prevent overheating, particularly in hot environments. It’s like oiling a bike chain for a smooth ride.

The Future of Single- and Three-Phase Motors

What’s next for these motors? The future’s bright, with some exciting trends.

High-Efficiency Standards (IE3/IE4)

Efficiency is king in 2025, with IE3 (90-95% efficiency) and IE4 (96%+) standards becoming the norm, especially for three-phase motors. Driven by regulations like the EU’s Ecodesign Directive, these motors cut energy use, saving money and the planet. It’s like upgrading to a hybrid car for better mileage.

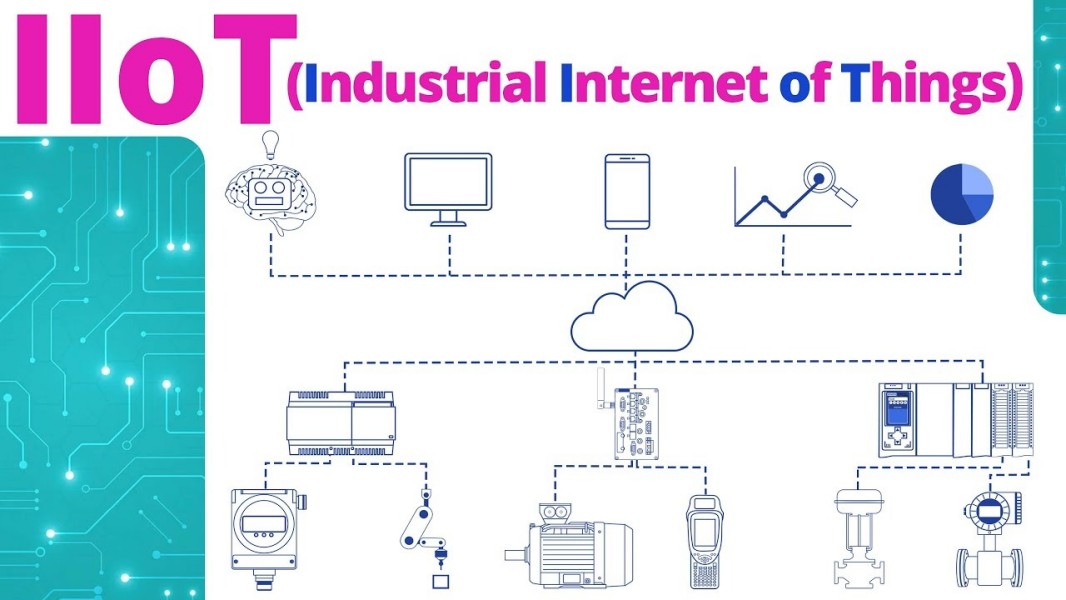

IoT and Smart Motor Integration

Imagine a motor that alerts you before it fails. IoT-enabled motors, especially three-phase ones, use sensors to monitor performance and predict maintenance needs. This reduces downtime for both motor types, like a smartwatch tracking your health to prevent issues.

![IIoT Integration IIoT Integration]()

FAQs About Single-Phase and Three-Phase Motors

1. What happens if I use a single-phase motor in a three-phase system?

It won’t work properly unless a converter is used—risk of damage is high.

2. Can I convert single-phase to three-phase power?

Yes, using a phase converter, though it adds cost and complexity.

3. Are three-phase motors always better?

Not always—only when higher torque, efficiency, or power is needed.

4. Which motor is more eco-friendly?

Three-phase motors, thanks to lower energy loss and longer lifespan.

5. Is maintenance more expensive for three-phase motors?

Slightly, but their durability and reliability often make up for it.

6. Can I run a three-phase motor on a single-phase supply?

Yes, but you’ll need a phase converter or VFD (Variable Frequency Drive) designed to handle the conversion. Performance may be affected.

7. Are single-phase motors less efficient?

Generally, yes. They produce more heat and less consistent torque compared to three-phase motors, making them less suitable for heavy-duty use.

8. Is maintenance easier with single-phase motors?

For basic applications, yes. However, three-phase motors tend to have longer life cycles and fewer vibration-related issues over time.

9. What about energy bills?

Three-phase motors usually consume less energy per unit of work and are often more cost-effective for continuous operation.

![Introduction Introduction]()

Conclusion

There’s no universal answer—choosing between a single-phase and a three-phase motor depends on your specific application, budget, and infrastructure. Single-phase motors are perfect for light-duty use, while three-phase motors are the clear winner in industrial or high-demand environments.

Get the right fit, and your machines will thank you with smooth, reliable performance for years.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी