Introduction

Ever looked at a motor’s spec sheet and wondered what those numbers—2, 4, 6, or 8 poles—are all about? They’re not just random digits; they’re the secret sauce behind how fast a motor spins and how much grunt it delivers. In 2025, with industries leaning hard into automation and efficiency, understanding motor poles is like knowing the playbook for picking the perfect motor. Whether you’re running a conveyor belt or a massive pump, the number of poles in your motor can make or break performance.

In this article, I’ll break down what motor poles mean, dive into the differences between 2, 4, 6, and 8-pole motors, and help you choose the right one for your needs. Meanwhile, tailored to fans, mixers, or pumps to show you specific motor pole selection. Ready to unravel the mystery? Let’s get spinning!

![3 phase motor 3 phase motor]()

What Are Motor Poles?

Motor poles are like the heartbeats of an electric motor, determining how it performs. In simple terms, poles refer to the number of magnetic poles in the motor’s stator—the stationary part that creates a rotating magnetic field. This field interacts with the rotor, making it spin to produce mechanical power. The more poles, the slower the motor spins, but with more torque. Think of it like gears on a bike: fewer poles are like high gear for speed, while more poles are like low gear for power.

Basics of Motor Operation

Here’s the gist: in an AC motor, like the three-phase induction motors common in industry, the stator generates a rotating magnetic field. The number of poles dictates how fast that field rotates, which directly affects the rotor’s speed. For a 60 Hz power supply (common in the U.S.), a 2-pole motor spins at about 3,600 RPM, while a 4-pole motor drops to 1,800 RPM. It’s like setting the tempo of a song—the poles decide how fast the motor dances.

Why Pole Count Matters

Why should you care about poles? Because they’re the key to matching a motor to your task. Need blazing speed for a fan? Go for fewer poles. Need brute strength for a heavy conveyor? More poles are your friend. Pole count affects speed, torque, efficiency, and even energy costs, making it a critical factor in industries where motors eat up over 70% of electricity. Get it wrong, and you’re stuck with a motor that’s either too weak or wasting energy.

![electric motor electric motor]()

Understanding Pole Configurations

Pole configurations—2, 4, 6, or 8—are like different flavors of ice cream, each suited to specific tastes. The number of poles determines the motor’s synchronous speed, calculated with the formula: Speed (RPM) = (120 × Frequency) / Number of Poles. For a 50 Hz system (common in Europe), a 2-pole motor runs at 3,000 RPM, a 4-pole at 1,500 RPM, a 6-pole at 1,000 RPM, and an 8-pole at 750 RPM.

✅ Synchronous Speed Formula

To calculate the theoretical speed of an AC induction motor (synchronous speed), use this formula:

Synchronous Speed (RPM) = (120 × Frequency) / Number of Poles

Where:

Common Motor Pole Configurations Sheet: 2, 4, 6, and 8

| Number of Poles | RPM at 50Hz | RPM at 60Hz | Torque Characteristics | Application Type |

| 2 Pole | 3000 | 3600 | High speed, low torque | Fans, pumps, grinders |

| 4 Pole | 1500 | 1800 | Balanced speed and torque | General industrial machinery |

| 6 Pole | 1000 | 1200 | Lower speed, higher torque | Conveyors, compressors, mixers |

| 8 Pole | 750 | 900 | Highest torque, lowest speed | Hoists, cranes, elevators |

Let’s dive into how these configurations shape motor performance.

How Poles Affect Motor Speed

The pole count is like the speed dial on your motor. Fewer poles mean a faster-rotating magnetic field, so the motor spins quicker. A 2-pole motor screams along at high RPMs, perfect for applications like fans or pumps. More poles slow things down, with 8-pole motors crawling at low speeds but delivering serious torque. It’s a trade-off: speed versus power, and the right choice depends on what you’re driving.

Torque and Power Considerations

Torque is the muscle that gets things moving, and more poles mean more torque. A 2-pole motor might zip along but struggle with heavy loads, while an 8-pole motor is like a bodybuilder, moving massive weights at a slower pace. Power output (measured in kW or HP) stays similar across pole counts, but the delivery changes—fewer poles prioritize speed, while more poles focus on force.

![8 pole rotor and 10 pole rotor 8 pole rotor and 10 pole rotor]()

Differences Between 2, 4, 6, and 8 Pole Motors

· 2-Pole Motors

2-pole motors are the speed demons of the motor world, spinning at 3,000–3,600 RPM depending on the power supply (50 Hz or 60 Hz). Their high speed makes them ideal for applications where quick rotation is key, but they sacrifice some torque. These motors are compact and efficient for light loads, like a sprinter dashing across the track.

✅ Advantages of 2-Pole Motors

Why go for a 2-pole motor? They’re fast, lightweight, and great for applications that don’t need heavy lifting. Their high RPMs mean smaller, cheaper designs, saving you money upfront. Plus, they’re efficient for continuous, low-torque tasks. It’s like choosing a zippy scooter for quick city trips—nimble and cost-effective.

✅ Common Applications

You’ll find 2-pole motors in centrifugal pumps, fans, and blowers—places where speed trumps torque. They’re common in HVAC systems, keeping air moving fast, or in small industrial pumps for water circulation. Think of them as the go-to for jobs that need to move quickly without heavy loads, like a courier zipping through traffic.

![iec motor iec motor]()

· 4-Pole Motors

4-pole motors strike a sweet spot, running at 1,500–1,800 RPM. They balance speed and torque, making them the most versatile choice for many industries. They’re like the all-purpose utility player on a sports team—good at everything without being extreme.

✅ Advantages of 4-Pole Motors

4-pole motors are the Goldilocks of motors: not too fast, not too slow, just right. They offer solid torque for medium loads while maintaining decent speed, making them efficient and reliable. Their balanced performance means lower maintenance costs, like a reliable sedan that handles city and highway driving with ease.

✅ Common Applications

These motors are everywhere—conveyor belts, compressors, and general machinery in manufacturing. They’re perfect for medium-duty tasks, like moving packages in a warehouse or powering a lathe in a workshop. Their versatility makes them the backbone of industries needing consistent performance.

![ie3 and ie4 motor ie3 and ie4 motor]()

· 6-Pole Motors

6-pole motors slow things down to 1,000–1,200 RPM, delivering higher torque for tougher jobs. They’re like the steady, powerful ox pulling a heavy cart—slower but stronger, ideal for applications needing more muscle than speed.

✅ Advantages of 6-Pole Motors

6-pole motors shine when torque is critical. They handle heavier loads with ease, and their slower speed reduces wear on components, boosting durability. They’re also quieter than 2-pole motors, making them great for noise-sensitive environments. It’s like choosing a heavy-duty truck for hauling over a sports car.

✅ Common Applications

You’ll see 6-pole motors in heavy conveyors, large pumps, and industrial mixers. They’re common in mining, where they power equipment moving tons of material, or in food processing for mixing dense ingredients. Their high torque makes them perfect for jobs that demand strength over speed.

![iec motors iec motors]()

· 8-Pole Motors

8-pole motors are the slow giants, running at 750–900 RPM with massive torque. They’re built for the toughest, heaviest loads, like a weightlifter moving massive barbells. These motors sacrifice speed for brute strength, making them niche but powerful.

✅ Advantages of 8-Pole Motors

8-pole motors are torque kings, ideal for applications where low speed and high power are non-negotiable. Their slower rotation reduces vibration and heat, extending lifespan in demanding conditions. They’re like the bulldozer of motors—slow but unstoppable.

✅ Common Applications

These motors power heavy-duty equipment like large industrial conveyors, crushers, and hoists in industries like cement or steel production. They’re also used in specialized applications, like wind turbine pitch control, where low speed and high torque are critical. Think of them as the muscle for the heaviest lifting.

Summary: Comparing 2, 4, 6, and 8-Pole Motors

Let’s put it side by side.2-pole motors (3,000–3,600 RPM) are fast but low-torque, great for fans.4-pole motors (1,500–1,800 RPM) balance speed and torque for conveyors.6-pole motors (1,000–1,200 RPM) offer higher torque for heavier loads, like mining equipment.8-pole motors (750–900 RPM) are slow but deliver massive torque for crushers. Each has its niche, like tools in a toolbox—pick the right one for the job.

![IE4 motor IE4 motor]()

Trade-Off Between 2, 4, 6, 8-Pole Motors

Speed vs. Torque

The pole count is a balancing act. Fewer poles (like 2) give you speed but less torque, while more poles (like 8) crank up torque at the cost of speed. It’s like choosing between a racecar and a tractor—speedy 2-pole motors zip through light tasks, while 8-pole motors grind through heavy ones. Your application decides the winner.

Efficiency and Energy Use

Do more poles mean better efficiency? Not quite. Efficiency depends more on design (like IE3 or IE4 standards) than pole count. However, slower motors (6 or 8 poles) can be more efficient for heavy loads since they reduce energy waste from slippage. 2-pole motors may use more energy at high speeds. It’s like driving at the right speed for fuel economy—match the poles to the task.

Choosing the Right Pole Count: Key Considerations

· Speed vs. Torque: Fewer poles = higher speed, more poles = higher torque

· Start/Stop Frequency: High-torque motors handle frequent starts better

· Fluid/Material Properties: Thick or heavy substances need slower, high-torque motors

· Energy Efficiency: Running close to optimal load/speed improves energy use

· Motor Size: More poles often require physically larger motors.

· Torque Demands: Higher poles = higher torque.

![motor component motor component]()

Application-Specific Motor Pole Selection

✅ Fans

Recommended Poles: 2-pole or 4-pole

Why:

· Fans typically require high rotational speed with low to moderate torque.

· 2-pole motors deliver higher speeds (3600 RPM) for small cooling fans.

· 4-pole motors (1800 RPM) are ideal for HVAC systems and large ventilation units.

Example:

✅ Mixers

Recommended Poles: 6-pole or 8-pole

Why:

· Mixers require high starting torque and slower speed for consistent blending.

· A 6-pole motor (1200 RPM) offers better control for viscous materials.

· An 8-pole motor (900 RPM) is ideal for delicate or slow stirring processes.

Example:

✅ Pumps

Recommended Poles: Depends on pump type

Why:

· Centrifugal pumps benefit from high-speed 2-pole motors for volume flow.

· Positive displacement pumps need slower, high-torque motors—typically 6 or 8 poles.

Examples:

· 2-pole motors: Booster pumps, water circulation in HVAC

· 4-pole motors: General irrigation, sump pumps

· 6/8-pole motors: Slurry pumps, thick fluids, dosing pumps

![Industrial field Industrial field]()

Maintenance Tips for Multi-Pole Motors

Want your motor to last? A little care goes a long way, no matter the pole count.

Regular Inspections

Treat your motor like a car needing regular checkups. Every few months, listen for odd noises, check for vibrations, and test insulation resistance. This catches issues early, preventing costly breakdowns. It’s like spotting a small leak before it floods your basement.

Lubrication and Cooling

Motors need grease and airflow to stay happy. Lubricate bearings regularly to reduce friction, especially for high-torque 6- or 8-pole motors. Keep cooling vents clean to prevent overheating, particularly for fast-spinning 2-pole motors. It’s like keeping your laptop’s fan clear to avoid a meltdown.

The Future of Multi-Pole Motors

What’s next for motors with different pole counts? The industry’s evolving fast, with some exciting trends.

High-Efficiency Motors (IE3/IE4)

Efficiency is king in 2025, with IE3 (90-95% efficiency) and IE4 (96%+) motors becoming standard, driven by regulations like the EU’s Ecodesign Directive. These motors, regardless of pole count, cut energy use, saving money and the planet. It’s like upgrading to a hybrid car for better mileage.

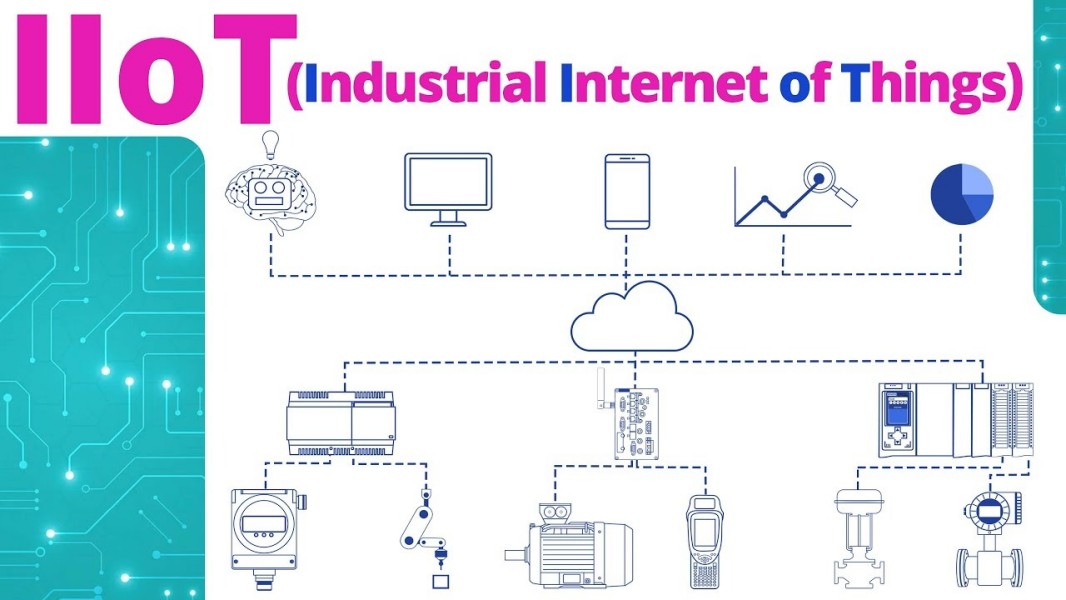

IoT and Smart Motor Technology

Imagine a motor that texts you when it’s tired. IoT-enabled motors with sensors are taking off, monitoring performance and predicting maintenance needs. This is a game-changer for all pole counts, reducing downtime like a smart assistant keeping your schedule on track.

![IIoT Integration IIoT Integration]()

FAQs About Motor Poles

1. Is a 2-pole motor better than a 4-pole motor?

Not necessarily. A 2-pole motor is faster but produces less torque. It depends on your application’s requirements.

2. Can a VFD change a motor’s pole count?

No. VFDs (Variable Frequency Drives) control motor speed by adjusting frequency, not pole count.

3. Are higher-pole motors more expensive?

Yes, generally due to more copper windings and larger stator cores.

4. Can I replace a 4-pole motor with a 6-pole motor?

Yes, but the speed and torque characteristics will change—check compatibility with your system.

5. Do more poles mean better efficiency?

Not always. Efficiency depends on design, materials, and operating conditions—not just pole count.

Conclusion

Motor poles—2, 4, 6, or 8—are the secret to tailoring a motor’s performance to your needs. They control the speed and torque that power everything from fans to heavy conveyors, making them critical in 2025’s automation-driven world. Whether you need the zippy speed of a 2-pole motor or the brute strength of an 8-pole beast, understanding pole differences helps you pick the perfect motor. With trends like IE3/IE4 efficiency and IoT integration, multi-pole motors are set to drive industries into a smarter, greener future.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी