A speed reducer, also known as a gear reducer, is an essential mechanical device that lowers rotational speed while increasing torque through components like gears and worms. It is used extensively in industrial applications where precise speed control and high power transmission are crucial. However, one of the most persistent challenges faced by engineers and operators alike is gear noise — a problem that affects not only equipment performance but also working environments and maintenance costs.

This comprehensive guide explores why speed reducers produce high noise, how to identify the root cause, and the best solutions and preventive measures to achieve quiet and efficient operation.

![1 1]()

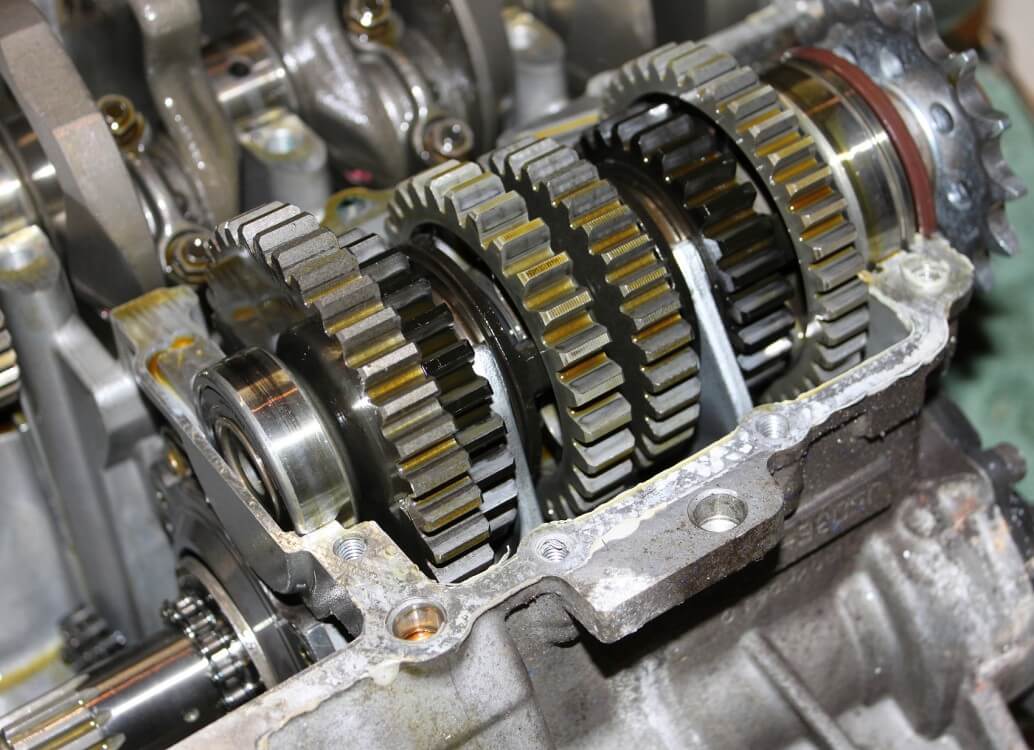

1. Understanding the Source of Gear Noise in Speed Reducers

Gear noise occurs primarily due to the meshing and vibration of gears during transmission. As gears rotate, their teeth engage and disengage, exciting the air within the reducer housing. The air’s compression and expansion generate acoustic waves, leading to noticeable noise.

According to AGMA 10FTM10-2010, an international standard for gear noise evaluation, even microscopic imperfections in gear design or lubrication can cause measurable sound levels.

1.1 Why It Matters

Excessive noise indicates friction, misalignment, or wear, which can shorten the lifespan of the gearbox.

Prolonged exposure to high noise also creates uncomfortable and unsafe work environments.

For precision industries (like robotics or semiconductor manufacturing), noise often correlates with vibration and efficiency loss.

![2 2]()

2. Common Causes of High Noise in Speed Reducers

Noise in a speed reducer rarely results from a single issue—it’s often a combination of mechanical, environmental, and operational factors. Below are the most frequent culprits and their corresponding solutions.

2.1 Poor Lubrication

Description:

Lack of proper lubrication or the use of degraded oil is the most common cause of gear noise. Without adequate oil film protection, metal-to-metal contact occurs between gears and bearings, producing abrasive “scratching” or “squeaking” sounds.

Example:

A sand screening machine once exhibited rising noise levels due to dry lubricant. Once the oil was replaced, the abnormal noise disappeared completely.

Solution:

Inspect oil levels every three months.

Replace lubricant at recommended intervals (typically every six months).

Use high-quality, brand-specific lubricants—never mix brands or viscosities.

For heavy-duty operations, consider synthetic lubricants with superior anti-wear and heat resistance properties.

2.2 Gear Wear, Damage, or Misalignment

Description:

Worn, broken, or misaligned gears cause rhythmic “clicking” or “rattling” noises. Over time, uneven friction leads to burrs, dents, or tooth surface damage, disturbing smooth meshing and causing vibrations.

Example:

In one industrial sand screening application, gear misalignment was identified as the noise source. After precision realignment, the system ran smoothly.

Solution:

Shut down the machine immediately if unusual clicking is heard.

Inspect gear teeth for wear patterns, burrs, or cracks.

Polish minor scratches with fine sandpaper.

Replace severely worn gears.

During reassembly, align gear shafts accurately using laser tools.

2.3 Bearing Failure or Misalignment

Description:

Worn or damaged bearings produce a continuous buzzing or humming sound, often accompanied by elevated temperatures. When installed incorrectly, bearings experience uneven load distribution, which accelerates wear.

Example:

In precision robotic reducers, worn bearing raceways led to repetitive knocking noises during high-speed operation. Replacing the bearings eliminated the issue.

Solution:

Use high-precision bearings with tight tolerance.

Verify bearing clearance before installation.

Avoid overloading and monitor for heat buildup.

Lubricate regularly with noise-reduction bearing grease.

2.4 Foreign Objects and Loose Components

Description:

Contaminants like metal debris, dust, or sand inside the gearbox can cause random “ticking” or “grinding” noises. Similarly, loose bolts or deformed housings can create impact sounds during rotation.

Example:

During assembly, leftover iron filings caused gear jamming and irregular knocking until the gearbox was disassembled and cleaned.

Solution:

Clean the gearbox thoroughly after assembly or maintenance.

Tighten all fasteners to proper torque specifications.

Use anti-vibration washers to prevent bolt loosening.

Ensure the gearbox base and foundation are level to prevent structure-borne noise.

2.5 Overload and Improper Installation

Description:

Excessive loading can deform gear teeth, causing dull humming or whining sounds. Misaligned couplings between the motor and reducer shafts result in non-concentric friction that amplifies vibration and noise.

Example:

In a linear motor system, uneven guide rail installation caused loud high-frequency noise. Re-aligning the system solved the issue.

Solution:

Avoid running the reducer at more than 80% of its rated torque for extended periods.

Use laser alignment tools to ensure shaft concentricity.

Perform vibration analysis during commissioning to confirm balance.

![3 3]()

3. Engineering Solutions to Minimize Gear Noise

At Victory Workshop, the manufacturing process focuses on gear design, precision machining, and meticulous assembly, ensuring minimal operational noise.

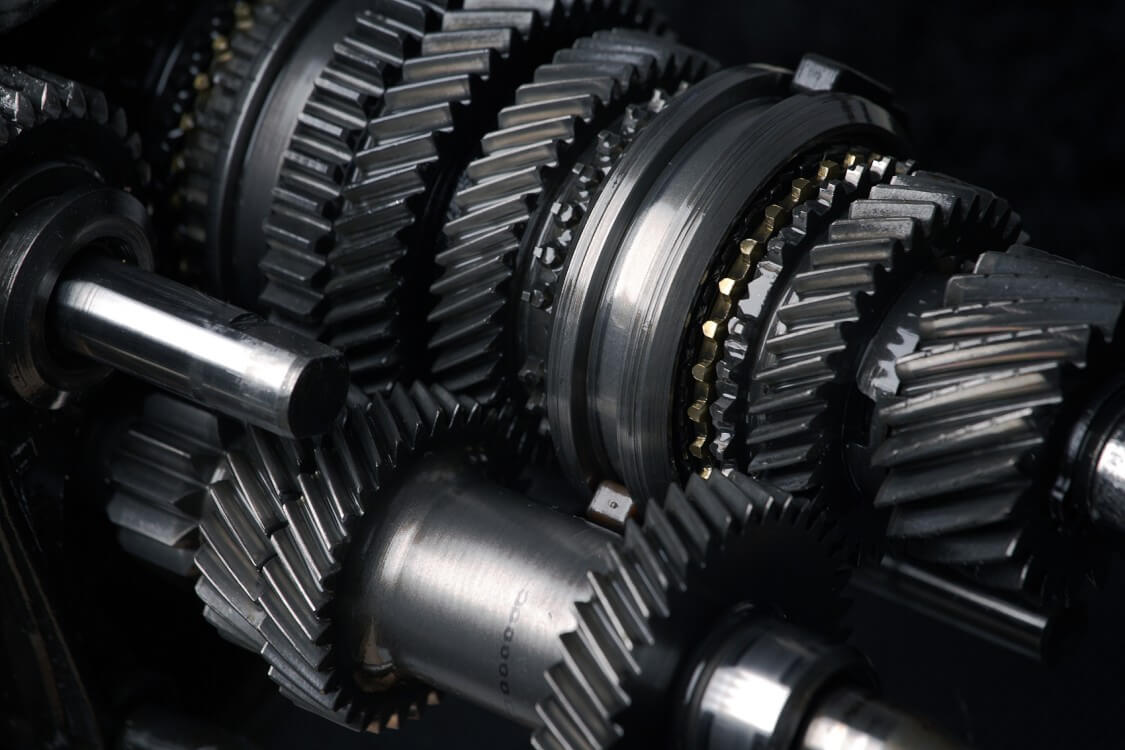

3.1 Gear Design Optimization

Gear Accuracy

The higher the gear’s manufacturing precision, the smaller the meshing clearance—leading to quieter operation. According to the American Gear Manufacturers Association (AGMA), high-grade gears significantly reduce noise.

Tooth Pitch and Pressure Angle Adjustment

Modifying these parameters increases meshing overlap, allowing multiple teeth to engage simultaneously. This reduces impact and enhances transmission smoothness.

Tooth Width Expansion

Increasing tooth width enlarges the contact area, boosting load capacity and reducing gear stress—therefore minimizing sound emissions.

All Victory Workshop gears are machined using CNC precision centers, maintaining dimensional errors below 1 micron, ensuring ultra-smooth meshing.

3.2 High-Precision Gear Processing

Operational Smoothness and Angular Accuracy

Any angular error per gear revolution introduces vibration. Maintaining tight tolerances ensures consistent rotation and low noise.

Contact Accuracy (Contact Spot)

The contact spot reflects the gear’s surface engagement quality. Poor contact increases localized stress, resulting in high-frequency sound.

Kinematic Accuracy

This measures how accurately the gear rotates through its pitch cycle. Excessive cumulative pitch error causes fluctuating angular velocity, producing “rumbling” low-frequency noise.

By maintaining strict runout and pitch deviation standards, the workshop ensures gears operate at peak smoothness with minimal resonance.

3.3 Noise Reduction During Assembly

Improper assembly is one of the top contributors to noise. Common assembly-related causes include:

Insufficient bearing preload, allowing shaft movement.

Misaligned gear shafts or coupling surfaces.

Transport shocks deforming housing or components.

Professional technicians with over a decade of experience at Victory Workshop meticulously perform:

Gear shaping and run-in procedures to enhance meshing.

Precision positioning using advanced measuring instruments.

Application of noise-reduction greases in high-speed systems.

These practices ensure optimal assembly accuracy and consistent gear engagement.

![4 4]()

4. Routine Maintenance to Prevent Gearbox Noise

Proper maintenance is crucial for sustaining quiet, efficient, and long-lasting reducer performance.

4.1 Regular Lubricant Inspection and Replacement

Check lubricant levels weekly.

Replace oil every six months or sooner in harsh conditions.

Always use the manufacturer-recommended lubricant type.

4.2 Noise Source Detection

4.3 Preventive Maintenance and Overhaul

Inspect gears, shafts, and bearings quarterly.

Replace worn or aging parts before failure.

Clean all interior surfaces during every inspection.

If abnormal noise is accompanied by vibration, overheating, or performance loss, stop the machine immediately and inspect for internal damage.

![5 5]()

5. The Science Behind Noise Reduction and Future Trends

Modern noise reduction in speed reducers focuses on three key aspects:

Design-Level Optimization:

Improved tooth geometry, higher overlap ratios, and optimized materials (like nitrided steel) help achieve quieter operation.

Material and Coating Innovations:

Using anti-vibration alloys and surface coatings with low friction coefficients significantly dampen noise.

Digital Diagnostics:

Smart gearboxes equipped with IoT sensors can now monitor vibration and temperature in real-time, predicting potential noise sources before they escalate.

As the industry evolves, the combination of AI-based predictive maintenance and advanced material science will make speed reducers quieter, smarter, and more efficient than ever.

![7 7]()

6. Conclusion

The high noise problem in speed reducers stems from a variety of mechanical and operational factors—from poor lubrication and gear misalignment to bearing failure and installation errors. Addressing these issues requires a comprehensive approach, combining precision design, advanced manufacturing, professional assembly, and preventive maintenance.

By implementing the best practices outlined in this article, manufacturers can reduce noise levels dramatically, extend the lifespan of gearboxes, and ensure smoother, safer, and more efficient industrial operations.

The future of industrial transmission lies in precision engineering and intelligent control systems—and solving the noise challenge is a critical step in achieving it.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी