Introduction

Three-phase asynchronous motors power a vast array of industrial and commercial applications, from pumps and fans to conveyor belts and elevators. Selecting the right starting method for these motors is critical to ensuring efficiency, minimizing grid impact, and extending equipment lifespan.

This comprehensive guide explores the primary starting methods for three-phase asynchronous motors, including direct start, voltage reduction start, soft start, and variable frequency drive (VFD) start. By understanding the principles, advantages, disadvantages, and ideal applications of each method, you can make informed decisions to optimize motor performance and reduce operational costs. This article dives deep into the technical details, offering actionable insights for engineers, facility managers, and industry professionals.

![Colorful industrial motors Colorful industrial motors]()

Understanding Three-Phase Asynchronous Motors

Three-phase asynchronous motors, also known as induction motors, are the workhorses of modern industry. Their robust design, reliability, and efficiency make them ideal for applications requiring consistent power. However, starting these motors can pose challenges due to high inrush currents, mechanical stress, and grid instability. The choice of starting method depends on several factors, including:

· Motor Power: Larger motors require methods that manage high starting currents.

· Grid Capacity: Limited grid capacity demands methods that minimize voltage drops.

· Load Characteristics: Heavy loads need higher starting torque, while light loads may not.

· Operational Requirements: Some applications require smooth starts or variable speed control.

By tailoring the starting method to these factors, you can enhance motor performance, protect equipment, and reduce energy costs. Let’s explore the four primary starting methods in detail.

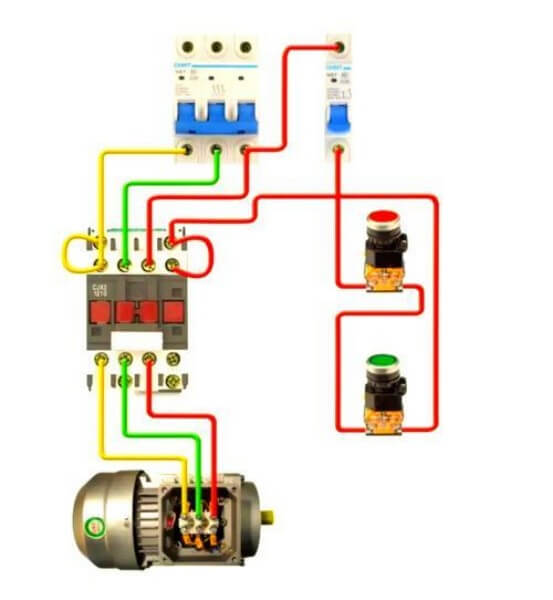

Direct Start: Simple but Powerful

How Direct Start Works

Direct start, also known as full-voltage start, connects the motor directly to the power supply at its rated voltage. This method instantly applies full power, enabling the motor to reach operating speed quickly.

![Full voltage starting Full voltage starting]()

Key Benefits of Direct Start

· Simplicity: Requires minimal equipment, typically just a circuit breaker or contactor.

· Cost-Effective: Low upfront costs due to basic setup requirements.

· Rapid Startup: Achieves full speed in seconds, ideal for time-sensitive applications.

Challenges of Direct Start

· High Starting Current: Generates 5–7 times the rated current, causing significant voltage drops that can disrupt other equipment on the grid.

· Mechanical Stress: Produces high starting torque, which may strain mechanical components like gears and couplings.

Ideal Applications for Direct Start

Direct start suits small motors (≤10kW) operating in environments with robust grid capacity, such as those powered by dedicated transformers. It’s best for light or no-load applications, such as small water pumps or fans, where high starting torque isn’t a concern.

Why Choose Direct Start?

For small-scale operations with simple requirements, direct start offers an economical and straightforward solution. However, its high inrush current limits its use in larger systems or grids with limited capacity.

![fan fan]()

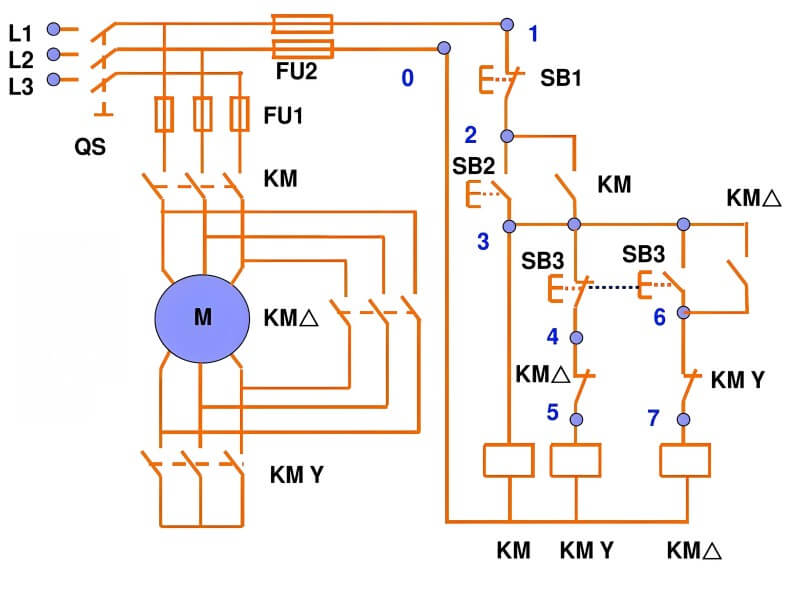

Voltage Reduction Start: Balancing Power and Control

When motor power exceeds 10kW or grid capacity is limited, voltage reduction start becomes a viable option. This method lowers the starting voltage to reduce inrush current, protecting both the motor and the grid. The most common approach is the star-delta (Y-Δ) configuration.

Star-Delta Starting Explained

Star-delta starting begins with the motor’s stator windings connected in a star (Y) configuration, reducing the voltage across each phase to approximately 57.7% of the rated voltage (1/√3). This lowers the starting current and torque to one-third of direct start values. Once the motor reaches a stable speed, the windings switch to a delta (Δ) configuration, applying full voltage for normal operation.

![Star-delta starting with reduced voltage Star-delta starting with reduced voltage]()

Advantages of Star-Delta Starting

· Low Equipment Cost: Requires only a star-delta starter, keeping expenses minimal.

· Reduced Starting Current: Limits inrush current to protect the grid.

· Simple Setup: Easy to implement in systems with compatible motors.

Limitations of Star-Delta Starting

· Low Starting Torque: Torque is reduced to one-third of direct start, making it unsuitable for heavy loads.

· Motor Compatibility: Only works with motors designed for delta connection at rated voltage (e.g., 380V).

· Abrupt Transition: Switching from star to delta can cause a minor torque surge, impacting mechanical components.

Best Use Cases for Star-Delta Starting

Star-delta starting excels for medium-power motors (10–75kW) in light or no-load applications, such as fans, centrifugal pumps, or compressors. It’s a cost-effective choice for facilities seeking to balance performance and grid stability without investing in advanced systems.

Why Opt for Star-Delta?

Star-delta starting offers a practical compromise for medium-sized motors, delivering lower starting currents at a fraction of the cost of more advanced methods. However, its limited torque makes it less suitable for heavy-duty applications.

![pump pump]()

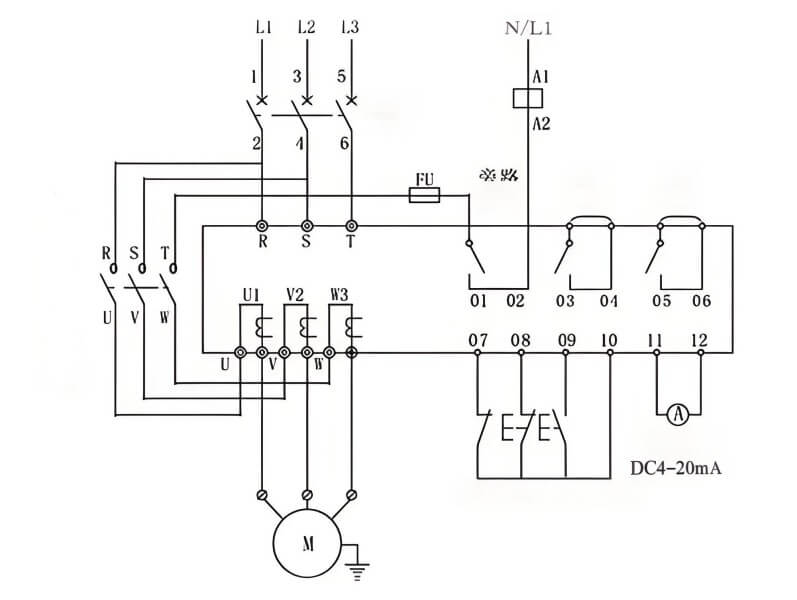

Soft Start: Smooth and Controlled Power Delivery

What Is Soft Start?

Soft start employs power electronic devices, such as thyristors, to gradually increase the voltage applied to the motor. This results in a smooth acceleration from zero to rated speed, minimizing electrical and mechanical stress.

![Soft start Soft start]()

Benefits of Soft Start

· Low Inrush Current: Limits starting current to 1.5–2.5 times the rated current, reducing grid impact.

· Smooth Operation: Eliminates torque spikes, protecting mechanical components and extending equipment lifespan.

· Comprehensive Protection: Includes built-in safeguards for overcurrent, overload, and phase loss, enhancing reliability.

· Soft Stopping: Allows gradual deceleration, ideal for applications like elevators or conveyor belts.

Drawbacks of Soft Start

· Higher Cost: More expensive than direct or star-delta starters due to advanced electronics.

· Not Ideal for Frequent Starts: Power electronic components have limited lifespans, making soft start less suitable for high-frequency starting scenarios.

Optimal Applications for Soft Start

Soft start shines in applications requiring smooth operation and minimal grid disturbance, such as elevators, large water pumps, or conveyor systems. It’s particularly valuable in settings with stringent power quality requirements, like hospitals or precision manufacturing facilities.

Why Choose Soft Start?

Soft start provides a controlled, reliable starting method for medium to large motors, offering a balance of performance and protection. Its ability to reduce mechanical and electrical stress makes it a go-to choice for sensitive applications.

![Automated equipment Automated equipment]()

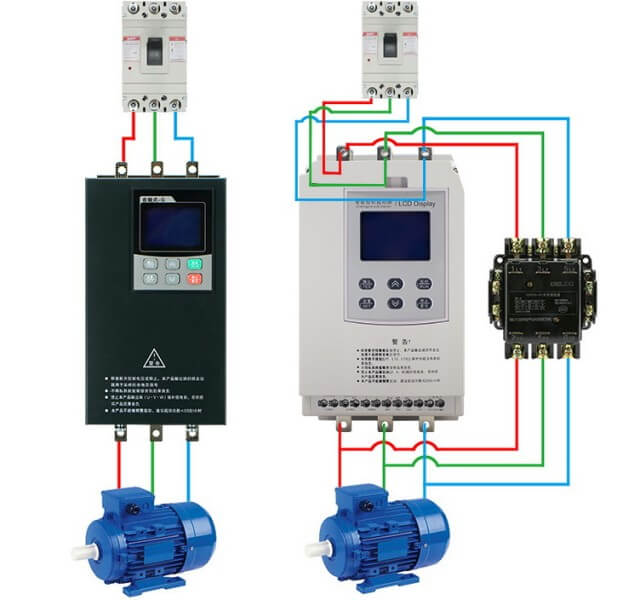

Variable Frequency Drive (VFD) Start: The Ultimate in Flexibility

How VFD Start Works

Variable frequency drive (VFD) starting uses a frequency converter to adjust both the frequency and voltage of the power supply, enabling precise control over motor speed and torque. This advanced method supports smooth starting and continuous speed regulation, making it highly versatile.

![Frequency conversion startup Frequency conversion startup]()

Key Advantages of VFD Start

1. Minimal Starting Current: Keeps inrush current at 1.2–1.5 times the rated current, preventing voltage fluctuations and reducing strain on the power distribution system. For instance, a 100kW motor using VFD start requires only 150–200A, compared to 500–700A for direct start.

2. Controllable Torque: Adjusts voltage and frequency (U/f control) to deliver high torque at low speeds, ideal for heavy loads like crushers or conveyor belts.

3. Stepless Speed Regulation: Enables continuous speed adjustment post-startup, optimizing performance for applications like pumps or fans that require variable speeds.

4. Energy Efficiency: Reduces power consumption significantly, especially for fans and pumps, where a 10% speed reduction can cut power usage by 27% (power scales with the cube of speed).

5. Smooth Operation: Gradually ramps up speed, minimizing mechanical wear and enhancing equipment longevity.

6. Advanced Protection: Includes real-time monitoring for overcurrent, overvoltage, phase loss, and grounding issues, ensuring reliable operation.

Challenges of VFD Start

· Limited for Frequent Starts: Power electronic components, like IGBTs, have lifespan limitations, making VFDs less suitable for applications requiring multiple starts per minute.

Ideal Applications for VFD Start

VFD starting is perfect for high-power motors or applications demanding precise speed control and smooth operation.

Common uses include:

· Heavy-Load Equipment: Crushers, conveyor belts, and large compressors benefit from high starting torque.

· Variable-Speed Applications: Pumps and fans that adjust speed based on demand, such as HVAC systems or water treatment plants.

· Grid-Sensitive Environments: Hospitals, data centers, and precision factories where voltage stability is critical.

· Energy-Conscious Operations: Facilities aiming to reduce energy costs through efficient speed regulation.

Why Invest in VFD Start?

VFD starting offers unmatched flexibility, energy savings, and protection, making it the gold standard for complex or high-demand applications. While the upfront cost is higher, the long-term benefits in efficiency and equipment longevity often justify the investment.

![Conveyor Belt 2 Conveyor Belt 2]()

Comparing Starting Methods: A Practical Guide

Choosing the right starting method involves weighing motor power, grid capacity, load requirements, and budget constraints. Here’s a breakdown to guide your decision:

1. 1. Motor Power and Grid Capacity

· Small Motors (≤10kW): Direct start is sufficient if grid capacity is robust.

· Medium Motors (10–75kW): Star-delta or soft start minimizes current surges in moderately sized systems.

· Large Motors (>75kW): Soft start or VFD start is necessary to manage high power demands and protect the grid.

2. 2. Load Characteristics

· Light Loads: Star-delta or direct start works well for fans, small pumps, or compressors.

· Heavy Loads: VFD start or soft start provides the torque needed for crushers, conveyors, or large pumps.

3. 3. Cost and Functionality

· Budget-Conscious: Direct start and star-delta offer low-cost solutions for basic applications.

· High-Performance Needs: Soft start and VFD start provide smooth operation, speed control, and advanced protection for demanding environments.

4. 4. Grid Stability Requirements

· Stable Grids: Direct start or star-delta can suffice in industrial settings with dedicated transformers.

· Sensitive Grids: Soft start or VFD start minimizes voltage fluctuations in hospitals, data centers, or precision factories.

Summary: How to Choose the Right Starting Method

| Criteria | Recommended Starting Method |

| Motor Power ≤10kW | Direct On-Line Start |

| Motor Power >10kW | Star-Delta, Soft Starter, or VFD |

| Light Load | Star-Delta |

| Heavy Load | VFD or Soft Starter |

| Speed Control Required | VFD |

| Budget Constraints | DOL or Star-Delta |

| Sensitive Power Grid | Soft Starter or VFD |

| High Start Frequency | Star-Delta or DOL (not VFD) |

![engineer engineer]()

Practical Tips for Selecting the Right Starting Method

1. Assess Motor Specifications: Check the motor’s power rating and connection type (e.g., delta-compatible for star-delta starting).

2. Evaluate Grid Capacity: Work with your utility provider to confirm available power and avoid voltage drops.

3. Analyze Load Requirements: Determine whether the application involves light, variable, or heavy loads to match torque capabilities.

4. Consider Long-Term Costs: Factor in energy savings, maintenance costs, and equipment lifespan when comparing initial investments.

5. Consult Experts: Engage electrical engineers or motor specialists to ensure compatibility and compliance with local regulations.

Future Trends in Motor Starting Technology

As industries prioritize energy efficiency and automation, motor starting technology continues to evolve.

Emerging trends include:

· Smart VFDs: Integration with IoT and AI enables real-time monitoring, predictive maintenance, and optimized performance.

· Energy-Efficient Designs: Advances in power electronics reduce harmonic interference and improve VFD efficiency.

· Hybrid Solutions: Combining soft start and VFD features to balance cost and performance for mid-range applications.

Staying ahead of these trends can help you future-proof your operations and maximize the value of your motor systems.

![coal mine coal mine]()

Conclusion: Optimize Your Motor Performance

Selecting the right starting method for three-phase asynchronous motors is a critical decision that impacts efficiency, reliability, and cost. Direct start offers simplicity for small motors, star-delta provides a cost-effective solution for medium loads, soft start ensures smooth operation, and VFD start delivers unparalleled flexibility and energy savings. By carefully assessing your motor’s power, grid capacity, load requirements, and operational goals, you can choose a method that enhances performance while minimizing downtime and costs.

Ready to optimize your motor systems? Evaluate your application’s needs, consult with experts, and invest in the starting method that aligns with your operational and budgetary goals. For advanced solutions like VFDs, explore reputable suppliers and ensure proper installation to unlock maximum efficiency and longevity.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी