![3-Phase Motors – Check and Repair 3-Phase Motors – Check and Repair]()

Introduction

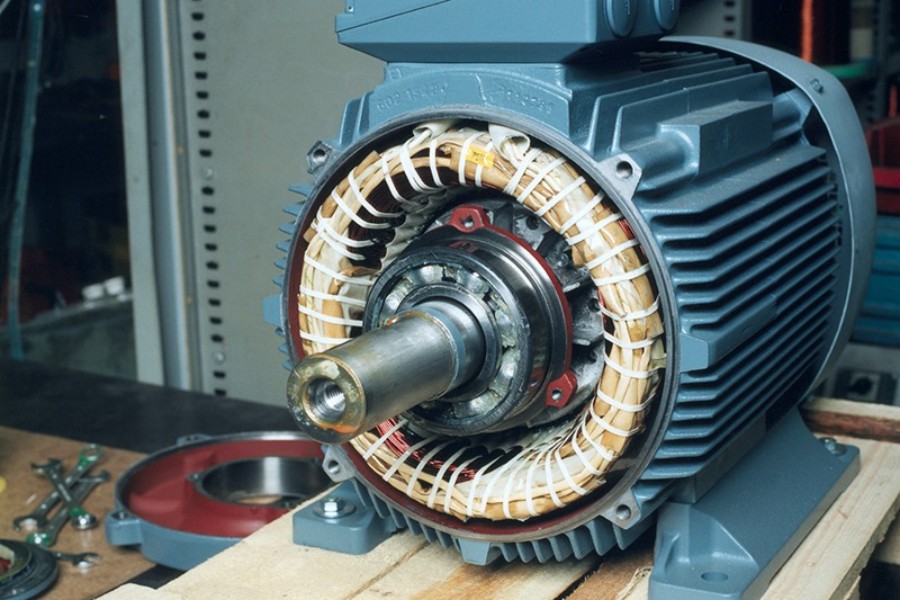

A 3-phase motor is the backbone of countless industries, from manufacturing and mining to agriculture and HVAC systems. These motors are designed for reliability, efficiency, and smooth operation. However, when something goes wrong, one of the first noticeable signs is abnormal vibration.

While a slight level of vibration is natural due to the rotating components, excessive or unusual vibration signals an underlying issue. Ignoring it can lead to reduced efficiency, overheating, mechanical wear, and even complete motor failure. The impact is not limited to the motor itself; vibration can transfer to connected machinery, causing misalignment, loosening of parts, and unplanned downtime.

This is why identifying, diagnosing, and repairing vibration problems in 3-phase motors is a priority for plant managers, maintenance engineers, and technicians. In this article, we will explore the most common causes of abnormal vibration, how to check and measure vibration levels, and the most effective repair and maintenance practices to restore the motor to optimal performance.

By the end, you’ll have a practical checklist for diagnosing vibration issues and the confidence to take corrective action before small issues turn into expensive breakdowns.

Understanding Normal vs. Abnormal Vibration

Not all vibration is harmful. In fact, every rotating machine has a baseline vibration signature. For example, small 3-phase motors operating at high speeds naturally generate slight vibrations that are within acceptable industry limits. These vibrations occur due to:

The challenge is identifying when vibration crosses the line from normal to abnormal.

Normal Vibration

· Typically measured in mm/s (velocity) or µm (displacement) using vibration analyzers.

· For motors up to 15 kW, ISO standards suggest vibration velocity should not exceed 2.8 mm/s RMS.

· Smooth, consistent vibrations without sudden spikes.

Abnormal Vibration

· Higher than recommended values (above 4.5–7.1 mm/s depending on motor size and speed).

· Sudden increases in amplitude or irregular patterns.

· Accompanied by unusual noise, overheating, or reduced efficiency.

Recognizing this distinction is crucial because it guides when to intervene. If caught early, vibration-related issues can often be corrected with minor adjustments, lubrication, or balancing. If ignored, they can escalate into catastrophic motor failure.

Victory - We Focus on ALL-IN-ONE Custom 3-Phase Industrial AC Motor Solution

Common Causes of Abnormal Vibration

Motor vibration can stem from three main categories of issues:

Mechanical Causes

· Misalignment, imbalance, or faulty bearings.

· Loose bolts or couplings leading to instability.

Electrical Causes

· Unbalanced supply voltage, faulty windings, or electromagnetic forces.

· Issues with harmonics or uneven phase loading.

Environmental Causes

· Poor foundation or structural resonance.

· Excessive humidity, dust, or temperature extremes.

Each category interacts with the others. For example, an electrical imbalance may create mechanical stress, which in turn causes bearings to wear prematurely. Therefore, effective troubleshooting requires a holistic approach rather than focusing on one possible cause.

![heavy-duty motor heavy-duty motor]()

Mechanical Causes of Motor Vibration

1. Shaft Misalignment

Shaft misalignment occurs when the motor shaft and the driven equipment shaft are not in perfect alignment. Even small deviations can cause cyclic vibrations, leading to premature bearing failure. Misalignment can be:

· Angular misalignment – shafts intersect at an angle.

· Parallel misalignment – shafts are offset but parallel.

· Combination misalignment – includes both angular and parallel misalignments.

Signs:

· High axial vibration levels.

· Excessive coupling wear.

· Elevated bearing temperatures.

Check & Repair:

2. Bearing Failure

Bearings are one of the most common sources of motor vibration. When bearings wear, pit, or lack lubrication, they produce high-frequency vibrations that worsen over time.

Causes of bearing failure:

· Inadequate lubrication or use of wrong grease.

· Overloading or improper installation.

· Contamination from dirt, dust, or moisture.

Signs:

· Audible grinding or whining noise.

· Heat generation around bearing housing.

· Vibration signatures at specific frequencies.

Check & Repair:

· Regular lubrication with manufacturer-approved grease.

· Replace worn bearings before they seize.

· Maintain cleanliness to prevent contamination.

3. Rotor Imbalance

Even a small imbalance in the rotor can generate vibration, especially at high speeds. Imbalance may result from uneven distribution of weight due to manufacturing defects, wear, or accumulation of dirt.

Signs:

Check & Repair:

4. Loose Components

Loose foundation bolts, couplings, or motor mounts are another frequent cause. Over time, vibration itself loosens components further, creating a vicious cycle.

Signs:

Check & Repair:

![Applications of 3-Phase AC Brake Motors Applications of 3-Phase AC Brake Motors]()

Electrical Causes of Motor Vibration

While mechanical faults are common, electrical issues are often overlooked as sources of vibration. Yet, they can be just as damaging.

1. Unbalanced Supply Voltage

An imbalance in supply voltage causes unequal magnetic pull on the rotor, leading to uneven torque and vibration.

Causes:

Signs:

Check & Repair:

· Measure phase voltages with a multimeter or power analyzer.

· Balance load distribution across phases.

· Inspect and tighten all electrical connections.

2. Magnetic Pull and Air Gap Irregularities

If the motor’s air gap (between rotor and stator) is not uniform, the rotor experiences uneven magnetic pull, causing vibration.

Causes:

Signs:

Check & Repair:

· Inspect air gap uniformity.

· Re-seat or re-center rotor.

· Consult manufacturer if defect is structural.

3. Stator Winding Issues

Shorted or damaged windings create magnetic imbalance, which reflects as vibration.

Causes:

Signs:

Check & Repair:

![pump pump]()

Environmental Causes of Motor Vibration

Beyond mechanical and electrical faults, the operating environment has a major impact on motor vibration. Even a perfectly aligned and electrically sound motor can experience abnormal vibration if installed in poor conditions.

1. Poor Foundation and Structural Resonance

If a motor is mounted on a weak or uneven foundation, vibration is amplified. Concrete foundations with cracks, thin base plates, or loose anchor bolts allow the motor to move slightly during operation. This results in structural resonance, where the natural frequency of the foundation matches the motor frequency, causing vibrations to intensify.

Check & Repair:

· Ensure foundations are solid and vibration-dampening pads are used.

· Re-grout damaged foundations.

· Use vibration isolators to minimize transmission.

2. Ambient Conditions

Extreme temperatures, moisture, and dust can affect motor stability. For example:

· Dust clogs ventilation and causes overheating.

· Moisture weakens insulation and corrodes bearings.

· Extreme cold stiffens lubricants, affecting smooth rotation.

Check & Repair:

· Use motors with appropriate IP ratings for the environment (e.g., IP55 for dust/water protection).

· Maintain proper enclosures in outdoor installations.

· Ensure sufficient ventilation or air-conditioning in hot areas.

3. External Vibrations

Sometimes vibration is not caused by the motor itself but by nearby machines. If heavy equipment such as crushers or hammers operate in the same area, their vibration can transfer to the motor via the floor or structure.

Check & Repair:

![Bearing Failures Bearing Failures]()

Methods to Check and Diagnose Motor Vibration

Identifying the cause of vibration requires accurate measurement and analysis. Here are the most common diagnostic methods:

1. Visual Inspection

The first step is always a physical check. Look for loose bolts, cracked foundations, worn couplings, or oil leaks. Often, a visual check reveals obvious causes of vibration.

2. Vibration Measurement Instruments

Special tools help quantify vibration:

· Vibration Meters: Measure overall vibration velocity (mm/s).

· Accelerometers: Detect high-frequency vibrations from bearings.

· FFT Analyzers (Fast Fourier Transform): Identify frequency-specific issues such as imbalance (1x RPM) or misalignment (2x RPM).

3. Electrical Tests

· Voltage imbalance check.

· Insulation resistance test.

· Current signature analysis to detect winding faults.

4. Thermal Imaging

Overheating often accompanies vibration. Infrared thermal cameras can spot hot spots in bearings, windings, or couplings.

5. Trend Monitoring

Modern plants use condition monitoring systems that continuously track vibration signatures. Any deviation triggers alerts, preventing sudden breakdowns.

![single & 3 phase motor single & 3 phase motor]()

Repair Techniques for Abnormal Vibration

Once the root cause is identified, appropriate corrective actions can be taken.

1. Mechanical Repairs

· Misalignment: Correct using laser or dial indicator alignment tools.

· Imbalance: Perform rotor balancing.

· Bearing Failure: Replace bearings and ensure proper lubrication.

· Loose Components: Tighten foundation bolts, couplings, and housing.

2. Electrical Repairs

· Unbalanced Supply Voltage: Balance phase loads and repair faulty connections.

· Winding Issues: Rewind stator or replace windings.

· Air Gap Issues: Re-seat rotor or replace damaged stator cores.

3. Environmental Adjustments

· Strengthen foundations.

· Install proper enclosures.

· Relocate motors away from vibration-heavy zones.

By addressing the specific fault, motors can be restored to smooth, reliable operation.

![Three-Phase Asynchronous Motor Three-Phase Asynchronous Motor]()

Preventive Maintenance to Avoid Vibration Issues

The best strategy is not just to repair vibration problems, but to prevent them from occurring.

1. Regular Lubrication

· Follow manufacturer schedules.

· Use the correct type and amount of grease.

· Avoid over-greasing, which causes overheating.

2. Alignment Checks

3. Load Management

4. Periodic Vibration Analysis

5. Environmental Protection

With proper preventive care, the motor lifespan can be extended significantly, while downtime and costs are minimized.

![315kw-4 315kw-4]()

Role of VFDs (Variable Frequency Drives) in Controlling Vibration

Variable Frequency Drives (VFDs) are increasingly used with 3-phase motors for speed and torque control. Interestingly, they also help in reducing vibration if applied correctly.

How VFDs Reduce Vibration:

· Soft Starting: Reduces mechanical stress during motor startup.

· Precise Speed Control: Prevents operation at resonance frequencies.

· Balanced Phase Supply: Modern VFDs maintain voltage balance across phases.

· Condition Monitoring: Some VFDs come with built-in vibration and thermal monitoring systems.

Caution with VFDs:

· Poorly configured VFDs may introduce harmonics, leading to electrical vibration.

· Always use filters and follow manufacturer setup guidelines.

When properly integrated, VFDs not only improve efficiency but also help maintain stable, vibration-free motor operation.

![Variable Frequency Explosion-Proof Motor Variable Frequency Explosion-Proof Motor]()

Case Studies of Vibration Problems in 3-Phase Motors

Case 1: Misalignment in a Pump Motor

A water treatment plant experienced recurring vibration in its 7.5 kW pump motor. Maintenance teams initially suspected bearing damage, but vibration analysis revealed high axial vibration, pointing to shaft misalignment. After realigning the motor and pump shaft using laser tools, vibration levels dropped by 60%, preventing further damage.

Case 2: Rotor Imbalance in a Fan Motor

In a cement plant, a 15 kW fan motor developed excessive vibration at running speed. On inspection, technicians found cement dust accumulation on the fan blades, causing imbalance. Cleaning and rebalancing the rotor solved the issue and restored smooth operation.

Case 3: Electrical Supply Imbalance

A textile mill reported overheating and vibration in multiple motors. Measurements showed one phase consistently had a 10% lower voltage. After fixing faulty connections in the distribution board, vibration levels returned to normal.

These examples highlight how different root causes require different solutions, reinforcing the importance of accurate diagnosis.

Advanced Diagnostic Tools for Motor Vibration

Modern technology has made it easier to identify the exact cause of abnormal vibration.

Portable Vibration Analyzers – Allow technicians to measure vibration at different points on the motor.

Online Condition Monitoring Systems – Continuously record data and issue alerts when vibration exceeds thresholds.

Spectrum Analysis (FFT) – Identifies unique frequency signatures of imbalance, misalignment, or bearing defects.

Ultrasound Detectors – Useful for early detection of bearing wear and lubrication issues.

Smart Sensors & IoT Devices – Mounted directly on motors, sending real-time data to cloud platforms for predictive maintenance.

By combining these tools, industries can shift from reactive repairs to predictive maintenance strategies, reducing downtime and costs.

![Installation and Maintenance for IE3 Electric Motors Installation and Maintenance for IE3 Electric Motors]()

Troubleshooting Checklist for Abnormal Vibration

Here’s a step-by-step approach for technicians to systematically diagnose and repair motor vibration:

Initial Inspection

· Check foundation bolts, couplings, and bearings.

· Listen for unusual noise.

Measure Vibration Levels

Check Electrical Supply

Analyze Vibration Patterns

Confirm with Advanced Tools

Apply Corrective Action

· Mechanical repairs (alignment, balancing, bearing replacement).

· Electrical repairs (rewinding, tightening connections).

· Environmental corrections (foundation reinforcement, isolation).

This systematic approach ensures issues are not misdiagnosed and repairs are efficient and effective.

![Yongzhuan 3 Phase AC Electric Motor Yongzhuan 3 Phase AC Electric Motor]()

Conclusion

Abnormal vibration in 3-phase motors is more than just an inconvenience—it’s a warning signal of deeper mechanical, electrical, or environmental problems. Left unchecked, it can lead to premature motor failure, increased downtime, and costly repairs.

By understanding the causes—ranging from shaft misalignment, bearing wear, rotor imbalance, electrical faults, to poor foundations—and applying proper diagnostic tools and repair methods, industries can extend the life of their motors.

Preventive maintenance, including regular lubrication, alignment checks, vibration monitoring, and load management, ensures that motors run smoothly and efficiently. Additionally, using VFDs and smart monitoring tools further reduces risks.

In short, keeping a close eye on vibration patterns not only protects your motors but also boosts overall plant productivity and reliability.

FAQs About Abnormal Vibration in 3-Phase Motors

1. What is the acceptable vibration level in 3-phase motors?

According to ISO standards, small motors should not exceed 2.8 mm/s RMS, while larger motors may allow up to 4.5 mm/s RMS.

2. Can electrical issues cause motor vibration?

Yes. Problems such as unbalanced supply voltage, winding faults, and uneven air gaps can cause abnormal vibration.

3. How often should vibration analysis be done?

For critical motors, vibration analysis should be performed every 6 months, while routine monitoring should be continuous for large industrial setups.

4. What is the quickest way to reduce motor vibration?

Start with alignment checks, tightening loose parts, and balancing the rotor. If vibration persists, perform electrical and advanced diagnostics.

5. Is it worth investing in smart vibration monitoring systems?

Absolutely. IoT-enabled sensors provide real-time data and predictive maintenance capabilities, helping industries save costs and prevent downtime.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी