Introduction

In modern industry, electrical motors are everywhere—powering pumps, fans, conveyors, compressors, and countless other machines. But not all motors are designed the same. Some motors can operate at only one rated voltage, while others, called dual-voltage motors, are designed to run at two different voltage levels.

For example, you may see a motor nameplate with ratings like 230/460V or 220/380V. At first glance, this may seem confusing—how can a single motor handle two voltages? The answer lies in the design of the stator windings and the way they are connected.

Dual-voltage motors are widely used in industries because they offer flexibility, efficiency, and global compatibility. Instead of requiring different motors for different power supplies, manufacturers can produce one motor that works across multiple voltage standards.

In this article, we’ll break down the engineering behind dual-voltage motors, how they operate, their advantages, applications, and best practices for installation and maintenance.

![Why choose IE3 Electric Motors Why choose IE3 Electric Motors]()

Understanding Dual-Voltage Design

The secret to a dual-voltage motor lies in its winding design and configuration. Unlike a single-voltage motor, where the stator winding is fixed to operate at a specific voltage, a dual-voltage motor allows for two different connection setups.

Basic Concept

A motor winding is essentially a coil of wire that produces a magnetic field when current passes through it.

The number of turns in the coil and how the coils are connected determine the operating voltage.

By rearranging the windings into different configurations, the motor can adapt to run at a higher or lower voltage.

Dual-Voltage vs. Standard Motors

Standard Motor – Designed for one voltage only (e.g., 400V).

Dual-Voltage Motor – Can be wired for two voltages, typically with a 2:1 ratio (e.g., 230/460V).

This flexibility is especially useful in regions where power supply voltages vary. For example, in the United States, many industrial plants use 230V, while others rely on 460V. Instead of stocking two separate motors, a single dual-voltage motor can meet both requirements.

The Role of Stator Windings

The stator winding is at the heart of a dual-voltage motor’s design. To understand why it can run at two voltages, we need to look at how the windings are connected.

Series Connection (High Voltage Operation)

When the windings are connected end-to-end (series), the voltage across each winding is divided.

This means the motor can handle a higher total voltage (e.g., 460V).

Current is lower in this mode, reducing copper losses.

Parallel Connection (Low Voltage Operation)

When the windings are connected in parallel, each coil receives the same voltage.

The motor can now run at a lower voltage (e.g., 230V).

Current is higher in this mode, but the power output remains the same.

Example

If a motor is rated for 230/460V:

At 230V, windings are connected in parallel.

At 460V, windings are connected in series.

This clever design allows one motor to serve two different power networks without any loss of performance.

![pump and ie3 electric motors pump and ie3 electric motors]()

How Dual-Voltage Motors Operate

The operation of dual-voltage motors depends on the way they are wired during installation. The motor doesn’t automatically “switch” between voltages—it must be configured correctly before running.

Running at Low Voltage (e.g., 230V)

Windings are placed in parallel.

The same voltage is applied to each coil, so they share the current load.

The motor draws more current, but the torque and power remain consistent.

Running at High Voltage (e.g., 460V)

Windings are placed in series.

Voltage is divided between coils, so each coil receives half the total supply voltage.

The motor draws less current, making it more suitable for high-voltage networks.

Typical Voltage Ratings

230/460V → Common in the U.S.

220/380V → Common in Asia and Europe.

240/415V → Used in regions with 50 Hz systems.

No matter the voltage, the motor delivers the same horsepower (HP) or kilowatt (kW) rating. The difference is only in how the current and voltage are distributed across the windings.

Advantages of Dual-Voltage Motors

The core advantage of a dual - voltage motor is its ability to adapt to two different voltage levels of power supplies. It can be used in different power supply environments without additional modification, and its flexibility and versatility are much higher than those of single - voltage motors.

1. Flexible Voltage Adaptation and Strong Scenario Compatibility

This is the most crucial advantage of dual - voltage motors. By changing the connection method of the windings (star / delta), it can adapt to two voltages (commonly 380V/220V, 440V/220V, etc.). Unlike single - voltage motors, it doesn't have to be matched with a fixed - voltage power supply. For example, a 380V/220V dual - voltage motor can operate normally with 380V three - phase power in a factory. If it is moved to a small workshop or an overseas environment with 220V three - phase power, it can be used just by re - wiring, without the need to replace the motor.

2. Reduction of Procurement and Inventory Costs

For enterprises that need to use motors across regions and standards (such as foreign - trade factories, multinational construction teams), there is no need to purchase multiple single - voltage motors separately for different voltage environments. Just stocking one type of dual - voltage motor can cover multiple scenarios. This can reduce the number of motors purchased. At the same time, it can also lower the variety and cost of warehouse inventory, and avoid the idling or waste of motors caused by voltage mismatch.

3. Reduction of Modification Risks for Voltage Adaptation

If a single - voltage motor needs to adapt to other voltages, its windings need to be disassembled and rewound. This is not only time - consuming and labor - intensive, but also may lead to a decrease in motor efficiency, serious overheating, or even burnout due to sub - standard winding processes (such as incorrect wire diameter and number of turns). The winding design of a dual - voltage motor is inherently compatible with two voltages. Just switch the wiring method (star / delta) according to the instructions on the nameplate. The operation is simple and there is no modification risk, which is safer.

4. Adaptation to Different Regional Grid Standards

The three - phase grid voltage standards vary in different countries and regions around the world. For example, in China and Europe, it is mostly 380V/400V, while in some Southeast Asian and North American regions, 220V/240V three - phase power may be used. Dual - voltage motors can directly adapt to these different - standard power grids. For export - type equipment (such as machine tools, water pumps, compressors), there is no need to customize motors for different markets, which greatly improves the export versatility of the equipment.

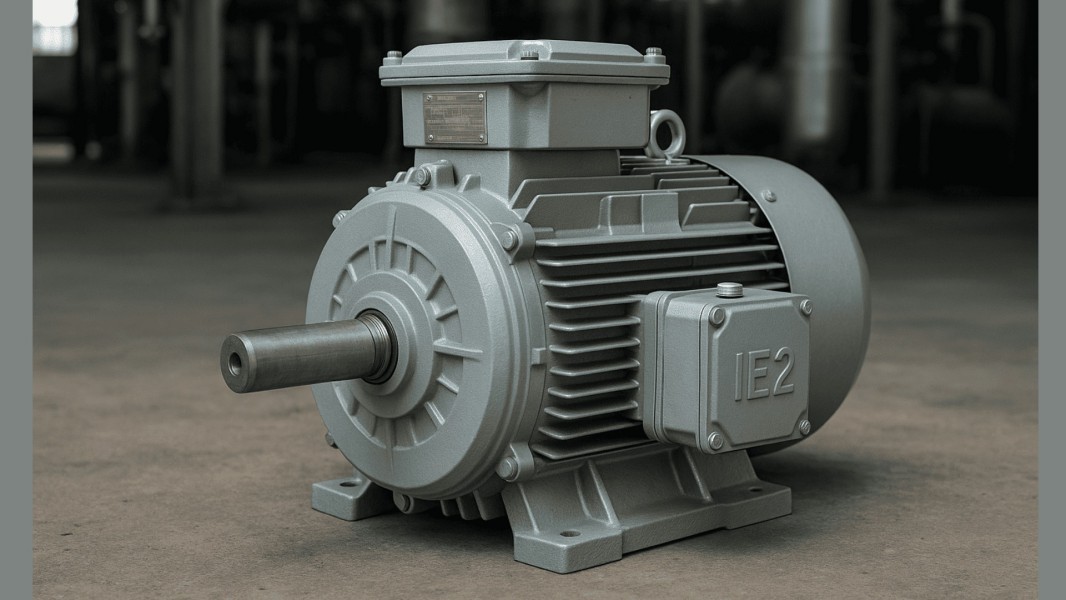

![Installation and Maintenance of ie2 electric motors Installation and Maintenance of ie2 electric motors]()

Common Applications of Dual-Voltage Motors

Dual-voltage motors are not just a clever engineering trick—they are practical solutions used across a wide range of industries. Their ability to adapt to two different voltage supplies makes them a go-to choice for OEMs (Original Equipment Manufacturers), exporters, and industries with variable power setups.

1. Mobile or Portable Industrial Equipment

Scenario Examples: Mobile air compressors, concrete mixers for field construction, and water pump units for temporary power supply.

Reasons: This type of equipment often needs to operate in different sites (such as construction sites, temporary workshops, outdoors), and the supply voltage may not be fixed (for example, the temporary power at a construction site may be 380V, and a small temporary shed may be connected to 220V three - phase power). A dual - voltage motor can ensure that the equipment starts normally under different power supply conditions without relying on a fixed voltage.

2. Export - type or Multinational - used Electromechanical Products

Scenario Examples: Machine tools, printing machines, food processing equipment exported to different countries, as well as globally - unified procurement equipment of multinational enterprises.

Reasons: It avoids the need to design motors separately due to different voltages in the target markets, reducing the R & D and production costs of the equipment. At the same time, it enables the equipment to directly adapt to the power grid of the importing country without the need to install additional transformers (transformers increase costs and energy consumption).

3. Multi - purpose Equipment in Small Factories or Family Workshops

Scenario Examples: Bench drills in small hardware factories, textile machines in family workshops, and feed crushers in township enterprises.

Reasons: In some small - scale places, there may be situations of "unstable voltage" or "the need to switch power sources" (for example, sometimes using 380V power from the factory, and sometimes using 220V three - phase power from a generator due to a power outage). A dual - voltage motor can adapt to both power supplies, preventing the equipment from stopping due to voltage problems.

4. Emergency or Backup Power Supply Scenarios

Scenario Examples: Backup negative - pressure fans in hospitals, backup cooling water pumps in data centers, and power motors for emergency lighting in shopping malls.

Reasons: During emergency power supply (such as generator power supply), the voltage may be different from that of the normal power grid (for example, the normal voltage is 380V, and the generator outputs 220V three - phase power). A dual - voltage motor can quickly switch the wiring in an emergency state to ensure that critical equipment does not stop running.

![3 phase ac induction motor pump 3 phase ac induction motor pump]()

Installation and Wiring Considerations

Dual-voltage motors provide flexibility, but only if they are wired correctly. Miswiring can cause overheating, reduced efficiency, or even motor failure.

1. Checking the Nameplate

Every dual-voltage motor comes with a nameplate diagram that shows how to wire the motor for either low or high voltage. This is the first reference point for installers.

2. Low-Voltage Connection (Parallel Wiring)

The motor windings are divided into multiple coil groups.

For low voltage (e.g., 230V), these groups are connected in parallel, ensuring each winding sees the same supply voltage.

This doubles the current but keeps the motor running safely.

3. High-Voltage Connection (Series Wiring)

For high voltage (e.g., 460V), windings are connected in series.

This means each coil receives half the voltage, preventing overheating.

The motor draws less current at higher voltage.

4. Risks of Improper Wiring

Wrong series/parallel setup can cause excessive current flow, overheating, or tripping of circuit breakers.

If a motor wired for 460V is accidentally connected to 230V, it may fail to start or run underpowered.

Conversely, wiring for 230V and connecting to 460V will cause immediate burnout.

5. Safety Guidelines

Always double-check the wiring diagram.

Ensure the supply voltage matches the motor connection.

Use certified electricians for industrial installations.

Consider motor protection devices like thermal relays and overload protectors.

Correct installation ensures that dual-voltage motors run efficiently and avoid costly downtime.

![Application of 3 phase AC Electric Motor Application of 3 phase AC Electric Motor]()

Comparison Table for Dual-Voltage Motor Wiring Methods (Taking 380V/220V as an Example)

This table focuses on the most common dual-voltage motors that use "star connection for 380V and delta connection for 220V". It clarifies the terminal connection logic, operation points, and risk warnings, and is applicable to most small and medium-sized dual-voltage three-phase asynchronous motors (such as the YE3-112M-4 motor).

| Comparison Dimension | Star Connection (Suitable for 380V Three-Phase Power Supply) | Delta Connection (Suitable for 220V Three-Phase Power Supply) |

| Applicable Supply Voltage | Line voltage of 380V (three-phase five-wire system/three-phase four-wire system, e.g., industrial power in factories) | Line voltage of 220V (common in some overseas power grids and small generator power supplies) |

| Winding Voltage Matching Logic | The rated phase voltage of the motor winding is 220V. Under star connection, the voltage across the winding equals the power supply phase voltage (380V/√3≈220V), which matches the rated value. | The rated phase voltage of the motor winding is 220V. Under delta connection, the voltage across the winding equals the power supply line voltage (220V), which directly matches the rated value. |

| 6-Terminal Connection Steps | 1. Locate the 6 terminals (marked U1, U2, V1, V2, W1, W2) in the motor terminal box.2. Use a connecting plate to horizontally short-circuit the three terminals U2, V2, and W2.3. Connect the three-phase power lines (L1, L2, L3) to terminals U1, V1, and W1 respectively.4. Tighten the terminal screws to ensure no loose connections. | 1. Locate the 6 terminals (marked U1, U2, V1, V2, W1, W2) in the motor terminal box.2. Use connecting plates to vertically short-circuit U1 with W2, V1 with U2, and W1 with V2 respectively (forming a delta loop).3. Connect the three-phase power lines (L1, L2, L3) to terminals U1 (or W2), V1 (or U2), and W1 (or V2) respectively.4. Tighten the terminal screws to ensure no loose connections. |

| Simplified Terminal Box Diagram | Short-circuit state: U2 - V2 - W1 (horizontal short-circuit)Wiring state: U1 connected to L1, V1 connected to L2, W1 connected to L3 | Short-circuit state: U1-W2, V1-U2, W1-V2 (vertical short-circuit in pairs)Wiring state: U1 connected to L1, V1 connected to L2, W1 connected to L3 |

| Key Notes | 1. Ensure the supply voltage is 380V. If mistakenly connected to a 220V power supply, the motor will suffer from "insufficient output, reduced speed, excessive current, and motor overheating" due to insufficient voltage.2. When short-circuiting U2, V2, and W2, ensure the connecting plates have good contact to avoid terminal ablation caused by poor local contact. | 1. Ensure the supply voltage is 220V. If mistakenly connected to a 380V power supply, the windings will be burned instantly due to excessive voltage (380V > rated 220V), and even short-circuit faults may occur.2. For delta connection, terminals must be connected strictly in accordance with "U1-W2, V1-U2, W1-V2". Reverse connection (e.g., U1 connected to U2) will cause winding short-circuit. |

| Common Errors and Consequences | - Error: Connecting power lines directly to U1, V1, W1 without short-circuiting U2, V2, W2.Consequence: No current flows through the motor, and it cannot start. | - Error: Short-circuiting U1 with U2, V1 with V2, W1 with W2 (horizontal short-circuit) and then connecting to a 220V power supply.Consequence: The windings are short-circuited, and the circuit trips or the windings burn out immediately after power-on. |

![ie3 electric motors ie3 electric motors]()

Customized Dual-Voltage Motor Wiring Operation Manual (Adapting to Multiple Voltage Specifications and Terminal Identifications)

1. Scope of Application

This manual applies to common dual-voltage three-phase asynchronous motors, including but not limited to the following voltage combinations:

380V/220V (most commonly used in China)

440V/220V (for some export equipment)

400V/230V (commonly used in European standards)

380V/660V (special specification for high-voltage motors)

2. Terminal Identification Guide (for non-U, V, W marking types)

Terminal markings of motors from different manufacturers may vary. The following is the corresponding relationship of common markings:

| Standard Marking (U, V, W System) | Alternative Marking 1 (A, B, C System) | Alternative Marking 2 (1, 2, 3 System) | Winding Function Description |

| U1 | A1 | 1 | Start end of the first-phase winding |

| U2 | A2 | 4 | End end of the first-phase winding |

| V1 | B1 | 2 | Start end of the second-phase winding |

| V2 | B2 | 5 | End end of the second-phase winding |

| W1 | C1 | 3 | Start end of the third-phase winding |

| W2 | C2 | 6 | End end of the third-phase winding |

Identification Tips:

Terminals are usually arranged in order (e.g., U1, V1, W1 in one row, U2, V2, W2 in another row).

Check the wiring diagram on the motor nameplate (the most authoritative reference).

Measure with a multimeter's resistance range: The resistance value between the two terminals of the same-phase winding is small (usually a few ohms), and the resistance between different phases is infinite.

![high-overload-capacity three-phase asynchronous motors high-overload-capacity three-phase asynchronous motors]()

3. Wiring Method Comparison Table for Different Voltage Specifications

3.1 380V/220V Motor (Most Commonly Used)

| Connection Type | Applicable Voltage | Wiring Steps (Taking U, V, W System as an Example) | Key Principle |

| Star (Y) | 380V | 1. Short-circuit U2, V2, W22. Connect power lines L1, L2, L3 to U1, V1, W1 | Phase voltage = 380/√3≈220V, matching the rated voltage of the winding |

| Delta (△) | 220V | 1. Short-circuit U1-W2, V1-U2, W1-V22. Connect power lines to the three connection points | Phase voltage = line voltage = 220V, matching the rated voltage of the winding |

3.2 440V/220V Motor (for Export to North America and Other Regions)

| Connection Type | Applicable Voltage | Wiring Steps | Key Principle |

| Star (Y) | 440V | 1. Short-circuit U2, V2, W22. Connect power lines to U1, V1, W1 | Phase voltage = 440/√3≈254V (the rated voltage of the winding must match) |

| Delta (△) | 220V | 1. Short-circuit U1-W2, V1-U2, W1-V22. Connect power lines to the three connection points | Phase voltage = 220V, matching the rated voltage of the winding |

3.3 380V/660V Motor (for High-Voltage Equipment)

| Connection Type | Applicable Voltage | Wiring Steps | Key Principle |

| Delta (△) | 380V | 1. Short-circuit U1-W2, V1-U2, W1-V22. Connect power lines to the three connection points | Phase voltage = 380V |

| Star (Y) | 660V | 1. Short-circuit U2, V2, W22. Connect power lines to U1, V1, W1 | Phase voltage = 660/√3≈380V |

![3 phase motor 3 phase motor]()

4. Wiring Operation Process (Standardized Steps)

4.1 Preparation

Cut off the power supply and confirm it is disconnected (test with an electroprobe).

Open the motor terminal box and clean up dust and debris inside.

Prepare appropriate connecting plates (copper, matching the terminals).

Prepare tools such as insulating gloves and screwdrivers.

4.2 Identification and Marking

Identify the 6 terminals according to Part 2 of this manual.

Mark each terminal with a marker pen (e.g., U1, U2, etc.).

Confirm the voltage-connection correspondence on the motor nameplate.

4.3 Connection Operation

Install connecting plates according to the wiring requirements for the corresponding voltage.

Connect the power lines (it is recommended to distinguish by color: L1-yellow, L2-green, L3-red).

Tighten all screws (apply moderate force to avoid thread stripping).

Check for short-circuit risks (whether exposed wires are in contact).

4.4 Testing and Confirmation

Recheck the correctness of the wiring before power-on.

Jog the motor (short-term power-on) and observe whether the rotation direction is correct.

Operate for 3-5 minutes, touch the motor housing, and confirm there is no abnormal overheating.

Measure the operating current, which should be within the rated current range.

5. Troubleshooting Guide

| Fault Phenomenon | Possible Cause | Solution |

| Motor does not start and makes no sound | Wiring error causing open circuit | Recheck terminal connections to ensure proper short-circuiting |

| Motor trips immediately after starting | Delta connection mistakenly connected to 380V power supply | Confirm the matching between voltage and connection, and rewire |

| Motor overheats severely and has low speed | Star connection mistakenly connected to 220V power supply | Switch to delta connection (when using 220V) |

| Abnormal noise during operation | Poor terminal contact or loose connecting plates | Retighten all connection points |

If need more detailed wiring guidance for a specific motor model (such as other models in the YE3 series), contact us and provide the specific model.

![iec motor iec motor]()

Maintenance of Dual-Voltage Motors

Like all motors, dual-voltage motors require regular maintenance to ensure long life and consistent performance.

1. Routine Checks

Inspect wiring connections for looseness or wear.

Look for signs of overheating or insulation breakdown.

Monitor noise and vibration, which can signal mechanical issues.

2. Voltage Compatibility Testing

Ensure the motor is connected to the correct supply voltage.

Periodically check the voltage balance between phases.

An imbalance greater than 5% can cause excessive heating.

3. Protecting Against Voltage Fluctuations

Use voltage stabilizers or automatic voltage regulators (AVRs) in areas with unstable power.

Motors running at low voltage may overheat, while those exposed to high voltage risk insulation failure.

4. Lubrication and Bearings

Bearings must be greased regularly to reduce wear.

Lack of lubrication increases friction, leading to abnormal heating and vibration.

5. Preventive vs. Reactive Maintenance

Troubleshooting Voltage Issues

Sometimes, even properly installed motors develop issues. Here are the most common problems related to dual-voltage operation:

1. Overheating

Cause: Incorrect wiring, overloading, or unbalanced voltage supply.

Solution: Re-check wiring, measure supply voltage, reduce load.

2. Reduced Efficiency

3. Incorrect Connections

4. Frequent Tripping of Breakers

5. Failure to Start

Proper troubleshooting ensures the motor continues to deliver reliable performance without unnecessary downtime.

![Three-phase asynchronous motor and control panel Three-phase asynchronous motor and control panel]()

Conclusion

Dual-voltage motors are a brilliant example of engineering flexibility. By allowing operation at two voltage levels—typically with a 2:1 ratio—they eliminate the need for separate motors for different supply conditions.

Their clever use of series and parallel winding connections ensures that the same motor can adapt to low-voltage and high-voltage networks without compromising efficiency or performance.

From industrial machinery and pumps to HVAC systems and exported equipment, dual-voltage motors are a preferred choice for industries worldwide. However, proper installation, wiring, maintenance, and troubleshooting are essential to avoid problems like overheating or reduced efficiency.

In short, dual-voltage motors offer the perfect combination of flexibility, cost-effectiveness, and reliability, making them one of the most valuable motor types in the modern industrial world.

FAQs About Dual-Voltage Motors

1. Can dual-voltage motors run on single-phase power?

No, they are designed for three-phase systems unless specifically built as dual-voltage single-phase motors.

2. What happens if a dual-voltage motor is wired incorrectly?

It can overheat, fail to start, or burn out completely depending on the mismatch between wiring and supply voltage.

3. Do dual-voltage motors affect efficiency?

No, efficiency remains the same whether running at low or high voltage, as long as it is wired correctly.

4. Are dual-voltage motors suitable for VFDs (Variable Frequency Drives)?

Yes, they can be used with VFDs, provided the wiring is set to the correct voltage level supported by the VFD.

5. Which industries benefit most from dual-voltage motors?

Industries involved in manufacturing, agriculture, HVAC, and export machinery benefit the most due to their versatility.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी