Introduction: The Importance of Induction Motors in the Philippines

As of 2025, the Philippine industrial sector is rapidly modernizing, with a strong focus on energy efficiency, automation, and sustainable infrastructure. From manufacturing plants and commercial buildings to municipal utilities and agriculture, the demand for durable and cost-effective induction motors is growing fast.

Induction motors are critical in driving essential systems—pumps, compressors, conveyor belts, fans, and HVAC units. To meet the rising demand, many global and local suppliers are stepping up to deliver high-quality solutions across Luzon, Visayas, and Mindanao.

![Application of 3 phase AC Electric Motor Application of 3 phase AC Electric Motor]()

What Are Induction Motors?

Let’s break it down. An induction motor is an AC electric motor that uses electromagnetic induction to create motion. Picture a stator generating a rotating magnetic field that pulls the rotor along, like a dancer twirling to the beat of a song. No brushes, no fuss—just a simple, reliable design that’s been around since the 1800s. You’ll find them in single-phase versions for smaller tasks like household appliances or three-phase models for heavy-duty industrial jobs. Their versatility makes them a staple across the Philippines.

Why Induction Motors Are Essential in the Philippines

Induction motors are like the heartbeat of Philippine industry. They power manufacturing lines churning out goods, pumps irrigating rice fields, and conveyor systems moving products in bustling warehouses. In a country where agriculture, manufacturing, and logistics are economic pillars, these motors are indispensable. Their rugged design and low maintenance make them perfect for the Philippines’ diverse and sometimes harsh environments, from humid farms to dusty factories. So, what’s fueling their demand in 2025?

Top Applications for Induction Motors in the Philippines

· Manufacturing (CNC machines, conveyor systems)

· HVAC and building automation

· Water pumping stations (rural and municipal)

· Mining and cement industries

· Agro-industrial processing

· Renewable energy systems

![Why choose IE3 Electric Motors Why choose IE3 Electric Motors]()

Philippines Market Demand of Induction Motor in 2025

The demand for induction motors in the Philippines is skyrocketing. The global induction motor market hit $20.3 billion in 2024 and is expected to grow at a 6.4% CAGR through 2034, with the Philippines riding this wave. Why? The country’s push for industrial automation, renewable energy, and infrastructure development is driving the need for efficient motors. From Manila’s manufacturing hubs to Davao’s agricultural plants, businesses are investing in motors to boost productivity.

What Makes a Great Induction Motor Supplier?

Before diving into the list, it's important to know what criteria define a top-tier supplier:

· Product Quality: High efficiency, NEMA or IEC-compliant motors.

· Technical Support: On-site service, installation help, and local repair centers.

· Availability: Fast delivery times and local inventory.

· Energy Efficiency Compliance: Offering IE3, IE4-rated motors.

Leading Induction Motor Suppliers in 2025 Philippines

Let’s meet the heavy hitters supplying induction motors in the Philippines. These 10 stand out for their quality, reliability, and market presence in 2025.

#1. Siemens Philippines – Global Power, Local Presence

Siemens Philippines, a subsidiary of Siemens AG, leads the market with its SIMOTICS motor line, which includes robust low and medium-voltage induction motors.

✅Why Siemens?

· High-efficiency IE3 and IE4 motors

· Seamless integration with automation systems

· Cloud-based monitoring via MindSphere

· Ideal for factories, water utilities, and industrial parks

✅Key Product: SIMOTICS SD200 Severe Duty Motors

✅Website: https://www.siemens.com/ph

![siemens siemens]()

#2. WEG Philippines – Trusted for Industrial Efficiency

WEG, a global giant from Brazil, has a solid Philippine presence through regional partners and direct supply chains.

✅What WEG Offers

· W22 series for industrial and severe-duty use

· IE3-rated energy-saving motors

· Custom motors for agriculture and mining sectors

· Strong after-sales support

✅Key Product: W22 NEMA Premium Efficiency Motor

✅Website: https://www.weg.net

![weg weg]()

#3. ABB Philippines (Baldor) – Smart Motor Systems

ABB Philippines combines smart technology with rugged motor engineering. Its acquisition of Baldor adds even more credibility in the field of premium induction motors.

✅ABB Benefits

· Baldor-Reliance motors for HVAC, water, and industry

· IoT-enabled for predictive maintenance

· NEMA Premium and IE4 efficiency ratings

· Extensive engineering support across Luzon

✅Key Product: Baldor-Reliance® RPM XE and Super-E® NEMA motors

✅Website: https://new.abb.com/ph

![abb abb]()

#4. Yongzhuan Motor – Leading Manufacturer From China

✅Background and Product Offerings

Yongzhuan-Motor Co., LTD is a comprehensive motor design and manufacturing enterprise with 25-years experience, which covers an area of 10,000 square meters and annual production of 3000,000 motors. Their main products are YE3(IE3), YE4(IE4) high-efficiency three-phase induction motor, YBX3 explosion-proof three-phase induction motor, gear motor, gear reducer, gearbox, and other special customized motors.

✅Key Industry Uses and Trusted Reputation

Their motors are extensively used in many industries, like mining and metalworking, due to their rugged design. The products have passed CE, authoritative third party quality testing and other certifications. Their products are mainly exported to the United States, Germany, Japan, Italy and other dozens of countries and regions.

✅Most Cost-effective and High Customization capability

Yongzhuan-Motor stands out for offering some of the most cost-effective induction motor solutions in the European market. Their ability to provide high-quality motors at competitive prices makes them an attractive choice for businesses looking to optimize their operational costs. Additionally, Yongzhuan-Motor excels in customization, offering tailored solutions to meet specific industry needs and unique application requirements.

✅Key Product: IEC Standard IE2 IE3 IE4 Induction Motor, Special 3-phase motor(Brake Motor, Explosion-proof Motor, VFD Motor), Helical Gear Motor, Cycloidal Gear Motor, Specialized Induction Motor for Gearboxes

✅Website: https://www.victory-motor.com/

![yongzhuan&victory motor yongzhuan&victory motor]()

#5. Mitsubishi Electric Asia – Precision Engineering in Motors

Mitsubishi Electric offers a full range of general-purpose and inverter-duty induction motors through its Philippine operations.

✅Key Advantages

· Known for motor-drive system integration

· Compact motors with low noise and vibration

· Strong in commercial, utility, and processing industries

✅Distributor: Meco Philippines, Inc.

✅Website: https://ph.mitsubishielectric.com

![Mitsubishi Electric Asia Mitsubishi Electric Asia]()

#6. Hitachi Asia Ltd. – Robust Industrial Induction Motors

Hitachi Asia Philippines provides motors for heavy industrial use, especially in power generation, oil and gas, and cement sectors.

✅Why Choose Hitachi?

· Large-frame motors with anti-corrosion features

· High thermal endurance for tropical climates

· Compliance with global energy standards

✅Website: https://www.hitachi.com.sg

![Hitachi Hitachi]()

#7. Schneider Electric Philippines – Energy-Saving Motor Solutions

Schneider Electric may be known for power systems, but they also offer compact low-voltage induction motors through partners.

✅Schneider Edge

· EcoDesign™ compliant motors

· Best for commercial, HVAC, and automation sectors

· Integration-ready with motor control centers (MCCs)

✅Website: https://www.se.com/ph

![schneider schneider]()

#8. Fuji Electric – Automation-Ready Motors for Every Industry

Fuji Electric Philippines delivers induction motors integrated with variable frequency drives (VFDs)—perfect for process control and energy saving.

✅Industry Use

· Packaging, bottling, and electronics manufacturing

· Easy installation and VFD-ready

· Compact and noise-controlled motors

✅Website: https://www.fujielectric.com

![Fuji Electric Fuji Electric]()

#9. Emerson Electric (Vertiv) – Reliable Motor Control Systems

While Emerson (Vertiv) focuses on power and data centers, their motor control technologies support induction motor optimization.

✅Why Emerson?

· Offers high-quality motor starters and soft starters

· Paired with induction motors for HVAC and data infrastructure

· Strong reseller network across NCR and Visayas

✅Website: https://www.vertiv.com

![emerson emerson]()

#10. Meiji Electric Philippines – Local Supplier, Global Standards

Meiji Electric is a homegrown brand providing IEC-standard induction motors for small-scale industry, commercial setups, and retail use.

✅Meiji Highlights

· Affordable general-purpose motors

· Strong nationwide dealer network

· Motor control panels and accessories available

✅Website: https://meijielectric.ph

![Meiji Electric Philippines Meiji Electric Philippines]()

Challenges Facing Induction Motor Suppliers

Even the best suppliers face hurdles in the Philippine market. Let’s look at the biggest challenges in 2025.

Import Dependency

The Philippines relies heavily on imported motors, with China, Japan, and Taiwan supplying most of the 4,404 induction motor shipments recorded by August 2024. This dependency creates risks like supply chain delays and currency fluctuations. Local suppliers like Arizona and KHM must navigate these challenges to keep motors flowing, especially for time-sensitive industrial projects. It’s like trying to keep a kitchen stocked when the grocery store’s across the ocean.

Cost and Availability

Price volatility is a real headache. Material shortages, like copper and rare earth elements, drive up costs, while global demand spikes make motors harder to source. Suppliers like RS and Lockerbi work to keep prices competitive, but fluctuations can hit small businesses hard. Plus, lead times for custom or high-power motors can stretch to weeks, slowing down operations. It’s a balancing act between cost and availability.

![Key Features of Explosion Proof Electric Motors IE3 Key Features of Explosion Proof Electric Motors IE3]()

How to Choose the Right Induction Motor Supplier

Picking the right supplier is like choosing a dance partner—you need someone who moves with you. Here’s how to make the right choice.

Assessing Motor Quality and Specifications

Not all motors are created equal. Check the power rating (HP or kW), voltage (110 V to 440 V), and efficiency class (like IE1 or IE3). Consider your application—single-phase for small pumps or three-phase for heavy machinery? Look for durable designs, like those with E/B/F insulation for heat and moisture resistance. Suppliers like Yongzhuan Motor provides detailed specs to help you match the motor to your needs.

Evaluating Supplier Reliability

A great motor is only as good as the supplier behind it. Look for companies with strong local presence, like Arizona or KHM, or foreign manufacturers with excellent export experiences for years, like Yongzhuan Motor, for faster delivery. Check their customer support—do they offer technical guidance or quick repairs?

![Plenty Stock of IE2 Electric Motors Plenty Stock of IE2 Electric Motors]()

The Future of Induction Motors in the Philippines

What’s next for induction motors in the Philippines? The industry’s evolving fast, with some exciting trends on the horizon.

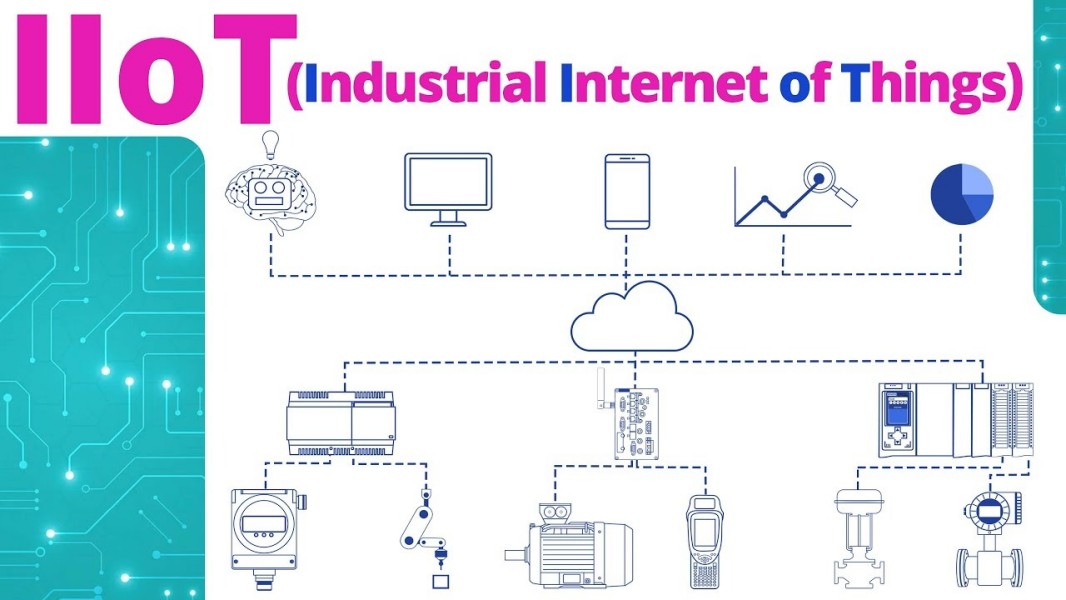

Smart Motors and IoT Integration

Imagine a motor that texts you when it’s overheating. That’s where IoT is taking us. Smart induction motors with sensors are gaining traction, offering real-time data on performance and maintenance needs. Suppliers like RS are starting to offer IoT-enabled motors, helping businesses prevent downtime. It’s like giving your motor a brain to think for itself.

Sustainability and Green Solutions

With energy costs rising and environmental concerns growing, green motors are the future. The Philippines is pushing for energy-efficient motors (IE3 and IE4) to cut industrial power use, which accounts for over 70% of electricity in some sectors. Suppliers like Yongzhuan Motor and ABB are stocking high-efficiency motors to meet these demands, helping businesses save money and the planet.

![IIoT Integration IIoT Integration]()

Frequently Asked Questions (FAQs)

1. Which induction motor brand is best for Philippine industries?

Answer: Brands like Siemens, ABB, and WEG are ideal for their energy efficiency, tropicalized builds, and local availability.

2. Are induction motors energy efficient?

Answer: Yes. Modern motors are rated IE3 or higher, meaning they consume less power over long operational hours.

3. Where can I get cost-effective IEC-compliant IE3/IE4 motors that can be customized in small quantities?

Answer: As a leading manufacturer of induction motors from China, Yongzhuan Motor can provide efficiency motors that comply with IEC standards and support customization, which ranges from case size, power, frequency, voltage, poles, temperature, material to additional features of the motor. For speed requirements, a wide range of gearbox customer solutions are also available. With high quality raw materials and an excellent supply system in China, the price of induction motors is not too high. Yongzhuan Motor aims to provide customers with motor solutions to help them increase their sales margins!

4. Where are induction motors used the most in the Philippines?

Answer: Common in manufacturing, HVAC, agriculture, and water pumping systems.

5. Do these suppliers provide warranties and support?

Answer: Yes. Most suppliers offer 1 to 2 years warranty, technical support, and even on-site servicing.

![Installation and Maintenance of ie2 electric motors Installation and Maintenance of ie2 electric motors]()

Conclusion: Choosing the Right Motor Supplier in the Philippines

Finding the right induction motor supplier in the Philippines depends on your operational needs, energy targets, and after-sales expectations. Whether you’re running a manufacturing plant, utility service, or building automation project, you’ll benefit by choosing suppliers that offer technical support, compliance certifications, and localized service.

Always ask about:

· Efficiency ratings (IE3, IE4)

· Motor warranty coverage

· Delivery time and inventory

· On-site or remote support

For businesses looking to upgrade or maintain sustainable motor operations in 2025, these ten suppliers are your best bet for performance and peace of mind.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी