Overview of the Worm Gearbox Market for Conveying Systems in Poland

We observe Poland as one of Central Europe’s fastest-growing industrial hubs, driven by strong investments in manufacturing automation, logistics infrastructure, food processing, mining, and material handling systems. At the core of these industries are conveying systems, where worm gearboxes play a critical role due to their compact design, high torque output, smooth operation, and self-locking capability.

In 2026, Polish end users and system integrators increasingly demand worm gearboxes that deliver reliability, efficiency, long service life, and easy integration with various conveyor types, including belt conveyors, chain conveyors, roller conveyors, screw conveyors, and inclined conveyors.

Below, we present the Top 10 worm gearbox manufacturers widely used for conveying systems in Poland, combining established European leaders with competitive global challengers.

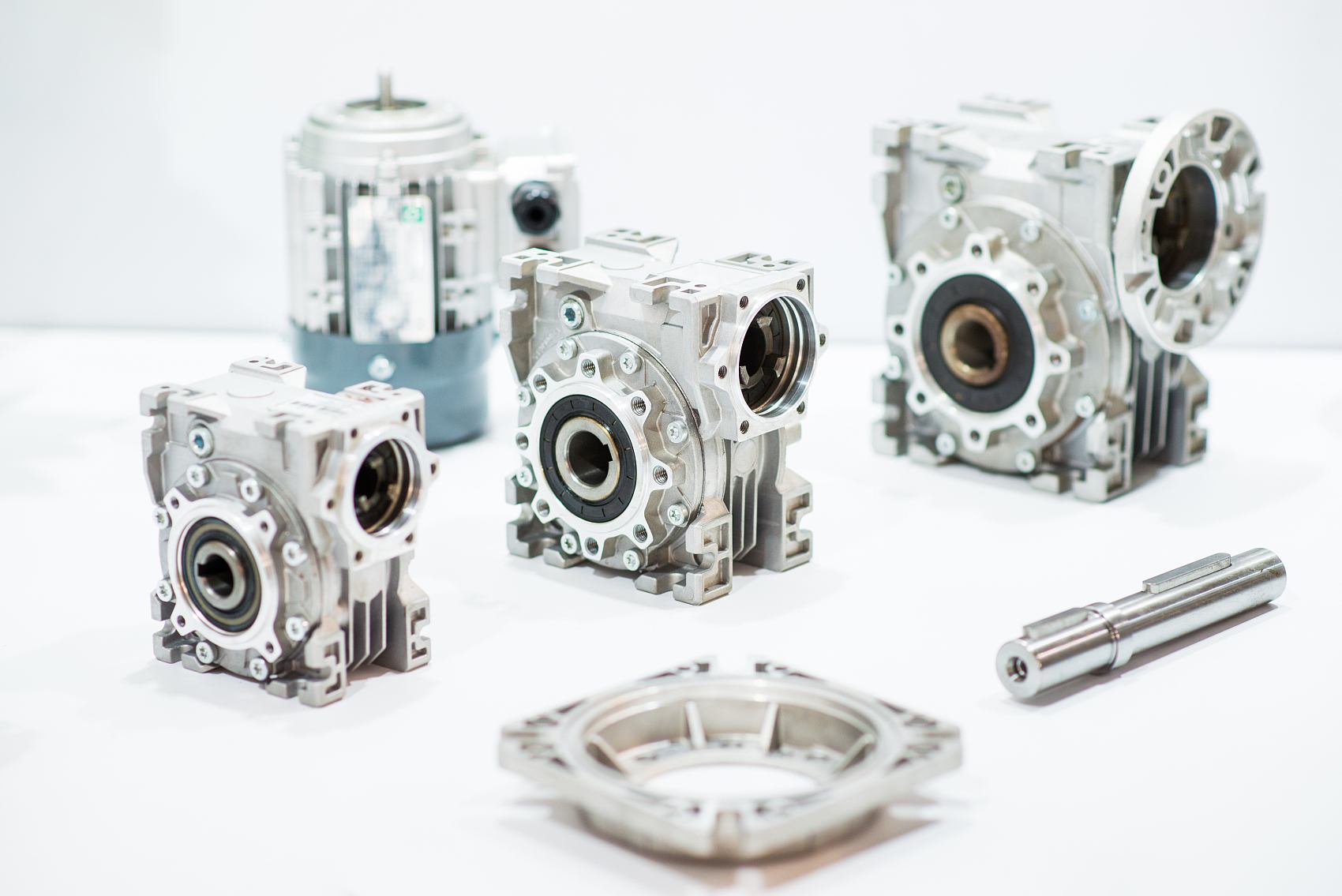

![worm gearbox worm gearbox]()

1. SEW-EURODRIVE – Market Leader in Conveyor Drive Solutions

We recognize SEW-EURODRIVE as the dominant supplier of worm and helical-worm gearboxes for conveying systems in Poland. Its gear units are extensively used in logistics centers, automotive plants, and bulk material handling facilities.

Key strengths:

Precision-engineered worm gear units

Excellent compatibility with belt and roller conveyors

High efficiency and long operating life

Strong local presence and after-sales support in Poland

SEW’s solutions are preferred for continuous-duty conveyor applications requiring stable torque and minimal downtime.

![sew-eurodrive sew-eurodrive]()

2. NORD Drivesystems – Robust Gearboxes for Heavy Conveyor Loads

We see NORD Drivesystems widely adopted in chain conveyors, inclined conveyors, and screw conveyors across Polish industrial plants. Its worm gearboxes are known for durability and modular design.

Key strengths:

High torque density

Corrosion-resistant housings

Flexible mounting positions

Strong performance in harsh industrial environments

NORD remains a trusted brand for food processing, mining, and bulk handling conveyors.

![nord nord]()

3. Bonfiglioli – Compact and Efficient Worm Gearbox Solutions

Bonfiglioli holds a strong position in Poland’s conveying systems market, particularly for compact conveyor layouts and space-restricted installations.

Key strengths:

Smooth and quiet operation

High reduction ratios

Excellent efficiency for inclined conveyors

Proven reliability in packaging and logistics conveyors

Bonfiglioli gearboxes are frequently selected for belt and roller conveyor systems requiring precise speed control.

![bonfiglioli bonfiglioli]()

4. Rossi – Heavy-Duty Worm Gearboxes for Industrial Conveyors

We observe Rossi gearboxes widely applied in heavy industrial conveying systems, including steel plants, cement facilities, and recycling lines in Poland.

Key strengths:

Exceptional mechanical strength

High load-bearing capacity

Long service life under continuous operation

Excellent thermal performance

Rossi is favored for large screw conveyors and inclined conveyors handling abrasive or high-density materials.

![蜗杆齿轮箱的白色背景 蜗杆齿轮箱的白色背景]()

5. Motovario – Versatile Solutions for Conveyor Applications

Motovario is well established in Poland for supplying cost-effective and reliable worm gearboxes for diverse conveyor systems.

Key strengths:

Motovario is commonly used in chain conveyors, belt conveyors, and automated material handling systems.

![NMRV Gearbox for Conveying equipment NMRV Gearbox for Conveying equipment]()

6. Varvel – Precision Worm Gearboxes for Automation Conveyors

We identify Varvel as a specialist manufacturer offering high-precision worm gearboxes for automated conveyor applications.

Key strengths:

High manufacturing accuracy

Compact footprint

Smooth torque transmission

Excellent compatibility with servo and induction motors

Varvel solutions are often found in roller conveyors and packaging lines across Poland.

7. Bauer Gear Motor – Reliable Gearboxes for Continuous Conveying

Bauer Gear Motor maintains a solid reputation for robust worm gearboxes used in continuous conveying operations.

Key strengths:

High operational reliability

Optimized for long duty cycles

Strong sealing and protection

Suitable for harsh environments

Bauer is commonly selected for industrial belt and chain conveyors requiring stable, uninterrupted operation.

8. STM Group – Flexible and Cost-Effective Conveyor Gearboxes

We see STM Group gaining traction in Poland due to its flexible gearbox configurations and competitive pricing.

Key strengths:

Modular gearbox systems

Strong torque performance

Suitable for screw and inclined conveyors

Good balance between price and quality

STM serves OEM conveyor manufacturers and system integrators effectively.

9. Winsmith (Regal Rexnord) – Proven Worm Gearbox Technology

Winsmith, part of Regal Rexnord, offers heavy-duty worm gearboxes trusted for industrial conveying systems in Poland.

Key strengths:

High shock-load resistance

Long operational lifespan

Proven design for bulk material handling

Reliable performance in screw conveyors

Winsmith gearboxes are particularly valued in mining and raw material conveying.

10. Victory-Motor – A Reliable Under-Dog Worm Gearbox Manufacturer

We position Victory-Motor as a reliable under-dog worm gearbox manufacturer increasingly recognized by Polish conveyor OEMs and distributors seeking cost-effective yet dependable solutions.

Company Overview

Victory Machinery Technology Co., Ltd. is a comprehensive motor and gearbox manufacturer with more than 20 years of industry experience. Its factory, located in Changzhou, Jiangsu Province, China, spans 15,000 square meters, employs over 50 skilled workers, and operates 11 production lines with an annual output of 300,000 motor and gearbox units.

Core Advantages

Specialized in gear motors and worm gearboxes

Products certified with CE, CCC, ISO9001

100% inspection before delivery

18-month warranty, exceeding industry norms

One-stop OEM & ODM customization services

Exported to 80+ countries with 100+ successful projects

Applications in Conveying Systems

We see Victory-Motor worm gearboxes increasingly applied in:

Belt conveyors for logistics and warehousing

Chain conveyors in manufacturing lines

Roller conveyors for automated sorting systems

Screw conveyors for bulk material handling

Inclined conveyors requiring stable torque and self-locking features

Victory-Motor stands out by offering engineering practicality, flexible customization, and competitive pricing, making it an ideal partner for mid-scale conveying projects in Poland.

![yongzhuan&victory motor yongzhuan&victory motor]()

Conclusion

We conclude that the Polish conveying systems market relies heavily on worm gearboxes due to their compact structure, high torque output, and operational stability. Leading European manufacturers such as SEW-EURODRIVE, NORD, and Bonfiglioli dominate high-end and mission-critical conveyor installations.

At the same time, value-driven manufacturers like Victory-Motor play an increasingly important role by supporting OEMs, integrators, and distributors seeking reliable, customizable, and cost-effective worm gearbox solutions.

As Poland continues to expand its logistics, automation, and industrial manufacturing sectors, worm gearbox suppliers that combine technical reliability, flexible production, and global supply capability will remain essential to the success of modern conveying systems.

![RV输出方式1 RV输出方式1]()

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी