Introduction to the European Conveyor Motor Market

Market Evolution and Industrial Demand

The European industrial landscape continues to evolve at a rapid pace, and at the heart of this transformation lies the conveyor system, a critical backbone of manufacturing, logistics, mining, and processing industries. As we move toward 2026, demand for 3-phase induction motors for conveyors is accelerating due to automation, energy efficiency regulations, and the expansion of high-throughput facilities across Europe. We observe that conveyor systems demand motors capable of operating continuously under varying loads, often in harsh environments, while maintaining consistent performance and low operating costs.

Why 3-Phase Induction Motors Dominate Conveyor Systems

Europe’s emphasis on sustainability, coupled with strict efficiency regulations, has positioned 3-phase induction motors as the preferred solution for conveyor applications. These motors deliver robustness, reliability, and efficiency that align perfectly with modern industrial expectations. From distribution centers in Germany to mining operations in Eastern Europe, conveyors powered by these motors ensure uninterrupted material flow. The supplier ecosystem has matured accordingly, with established manufacturers investing heavily in innovation, localized production, and service networks. Understanding this market is essential for identifying the top motor suppliers in Europe for 2026, particularly those capable of meeting the evolving technical and regulatory requirements of conveyor-driven industries.

![Polymer production line for conveying plastic pipes Polymer production line for conveying plastic pipes]()

Understanding 3-Phase Induction Motors for Conveyors

Core Operating Principles

3-phase induction motors are widely regarded as the industrial standard for conveyor systems due to their simple construction, high durability, and predictable torque characteristics. These motors operate on electromagnetic induction, eliminating the need for brushes or commutators, which significantly reduces maintenance requirements. For conveyor applications, this translates into fewer stoppages, longer service intervals, and improved operational continuity.

Key Performance Metrics for Conveyor Applications

Performance metrics such as starting torque, thermal stability, load adaptability, and efficiency class are especially critical in conveyor environments. Conveyors often handle variable loads, start and stop frequently, or operate continuously for extended periods. High-efficiency motors, particularly those compliant with IE3, IE4, and emerging IE5 standards, help reduce energy consumption while maintaining consistent speed and torque. European regulations have further reinforced the adoption of premium-efficiency motors, making compliance a non-negotiable factor when selecting suppliers. As a result, leading manufacturers differentiate themselves through advanced designs, superior materials, and integrated monitoring capabilities tailored specifically for conveyor operations.

![Punching and bending machine Punching and bending machine]()

Selection Criteria for Conveyor Motor Suppliers

Choosing the right supplier for 3-phase induction motors for conveyors involves far more than comparing price lists. We focus on suppliers that demonstrate proven reliability across diverse industries, supported by long operational lifecycles and minimal downtime. Lifecycle cost, rather than upfront investment, has become the dominant decision factor, particularly for large-scale conveyor installations.

Customization capability is another decisive criterion. Conveyor systems are rarely standardized, and suppliers that offer application-specific motor designs, tailored mounting options, and optimized cooling solutions provide a measurable advantage. Equally important is after-sales support. A strong European service network ensures rapid response, availability of spare parts, and technical assistance, all of which are vital for maintaining conveyor uptime. Suppliers that combine engineering expertise with regional presence consistently outperform competitors in demanding industrial environments.

TOP 20 Major 3-Phase Induction Motor Suppliers for Conveyors in Europe 2026

1. Siemens AG

Siemens AG remains a dominant force in the European motor market, offering a comprehensive portfolio of high-efficiency 3-phase induction motors engineered for conveyor systems. Their motors are renowned for precision engineering, advanced insulation systems, and seamless integration with automation platforms. Siemens’ strong focus on digitalization and predictive maintenance solutions further enhances conveyor reliability.

2. ABB Ltd

ABB continues to lead in energy-efficient motor technology, with conveyor motors designed to meet IE4 and IE5 efficiency standards. Their extensive manufacturing footprint across Europe ensures consistent quality and rapid delivery. ABB’s motors are widely used in logistics hubs and heavy-duty material handling applications.

3. Schneider Electric

Schneider Electric combines motor technology with advanced control solutions, making it a preferred supplier for intelligent conveyor systems. Their 3-phase induction motors emphasize energy optimization, thermal performance, and compatibility with variable frequency drives.

4. SEW-Eurodrive

SEW-Eurodrive specializes in drive solutions for conveyors, offering motors that excel in modularity and application-specific customization. Their strong presence in intralogistics and automated warehouses positions them as a top-tier supplier for 2026.

5. WEG Industries

WEG has expanded aggressively in Europe, delivering robust induction motors known for durability and competitive efficiency ratings. Their conveyor motors are particularly popular in mining and bulk material handling sectors.

6. NORD Drivesystems

NORD Drivesystems offers integrated motor and gearbox solutions optimized for conveyors. Their focus on corrosion-resistant coatings and hygienic designs makes them a strong choice for food and beverage conveyors.

7. Bonfiglioli Group

Bonfiglioli’s conveyor motors are engineered for precision and longevity. Their European manufacturing base ensures compliance with regional standards while offering tailored solutions for complex conveyor layouts.

8. Leroy-Somer (Nidec)

Leroy-Somer delivers high-performance induction motors with excellent thermal characteristics. Their motors are widely deployed in continuous-duty conveyor applications across Europe.

9. VEM Group

VEM Group is recognized for heavy-duty motors designed for extreme conveyor environments. Their products are frequently used in mining, cement, and steel industries.

10. Cantoni Motor

Cantoni Motor provides cost-effective yet reliable induction motors for conveyors, with a strong reputation in Central and Eastern Europe.

11. ATB Motors

ATB Motors focuses on industrial-grade solutions, offering conveyor motors with reinforced bearings and enhanced cooling systems.

12. Brook Crompton

Brook Crompton’s long-standing expertise in electric motors translates into dependable conveyor solutions with global support.

13. CG Power Europe

CG Power delivers standardized and customized induction motors suitable for diverse conveyor applications.

14. Regal Rexnord Europe

Regal Rexnord integrates motor technology with mechanical power transmission, offering complete conveyor drive solutions.

15. Lafert Group

Lafert Group specializes in premium-efficiency motors with compact designs, ideal for space-constrained conveyor systems.

16. Elvem Motors

Elvem Motors offers robust induction motors tailored for continuous conveyor operation in demanding industrial settings.

17. EBM-Papst Industrial Drives

EBM-Papst brings innovation in motor efficiency and compactness, increasingly relevant for automated conveyors.

18. MGM Motori Elettrici

MGM focuses on safety and braking solutions integrated with conveyor motors, enhancing operational control.

19. Motive S.p.A.

Motive provides versatile induction motors with a strong emphasis on energy efficiency and reliability.

20. CMG Motors Europe

CMG Motors Europe completes the top 20 with a portfolio designed for heavy-duty conveyor applications.

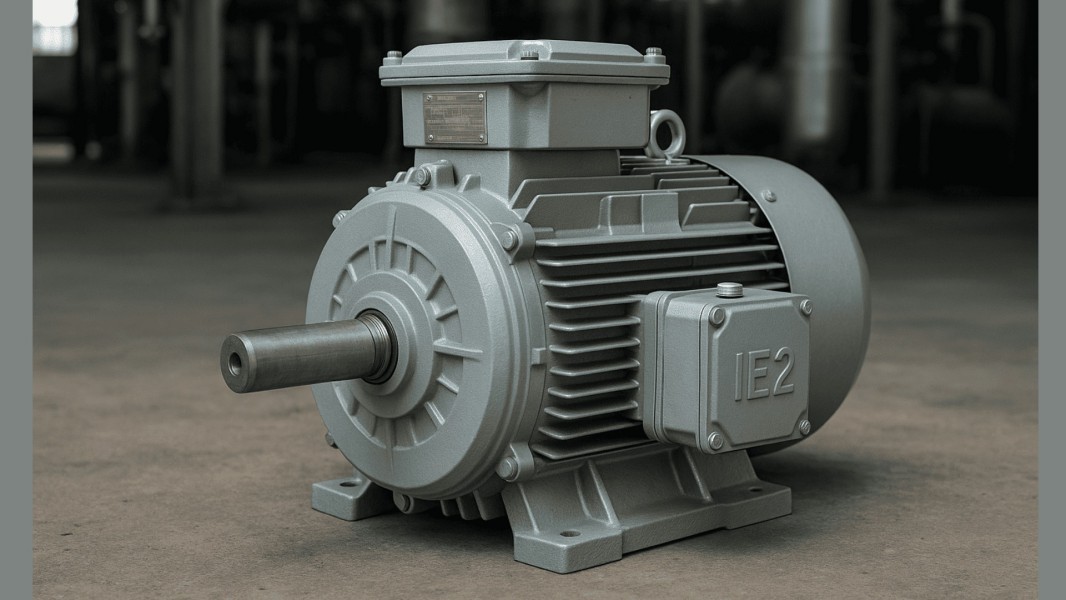

![3 phase motor 3 phase motor]()

Technology Trends Shaping Conveyor Motors in 2026

Technological innovation is redefining conveyor motor performance across Europe. The transition toward IE4 and IE5 ultra-premium efficiency motors is accelerating, driven by energy cost pressures and sustainability goals. Digital monitoring, embedded sensors, and smart diagnostics are becoming standard features, enabling predictive maintenance and reducing unplanned downtime. Sustainability initiatives further push suppliers to adopt recyclable materials and low-loss designs, aligning conveyor operations with broader environmental objectives.

Future Outlook for European Conveyor Motor Suppliers

Looking ahead to 2026, we anticipate continued investment in research and development, particularly in efficiency optimization and digital integration. Suppliers with strong European manufacturing bases and agile supply chains will gain a competitive edge. As conveyor systems become more automated and interconnected, motor suppliers that offer intelligent, efficient, and reliable solutions will define the future of industrial material handling in Europe.

Conclusion

The European market for 3-phase induction motors for conveyors is characterized by innovation, efficiency, and intense competition. The top 20 suppliers identified here represent the most reliable and forward-thinking manufacturers positioned to lead the market in 2026. By combining engineering excellence, regulatory compliance, and strong service networks, these suppliers ensure that conveyor systems across Europe operate with maximum reliability and efficiency.

FAQs

1. Why are 3-phase induction motors preferred for conveyors?

They offer durability, consistent torque, low maintenance, and high efficiency, ideal for continuous conveyor operation.

2. What efficiency standards are most relevant in Europe?

IE3 is widely adopted, while IE4 and IE5 are increasingly preferred for energy-intensive conveyor systems.

3. How important is after-sales support for conveyor motors?

Critical, as rapid service and spare parts availability directly impact conveyor uptime.

4. Are smart motors becoming standard in conveyors?

Yes, digital monitoring and predictive maintenance features are rapidly gaining adoption.

5. Which industries drive the highest demand for conveyor motors?

Logistics, mining, food processing, and manufacturing are the primary demand drivers.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Hrvatski

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Беларуская мова

Български

ქართული

guarani

ʻŌlelo Hawaiʻi

Lietuvių

Lëtzebuergesch

Македонски

Malti

मराठी